EVAP system: Difference between revisions

| Line 175: | Line 175: | ||

USA with ORVR: | USA with ORVR: | ||

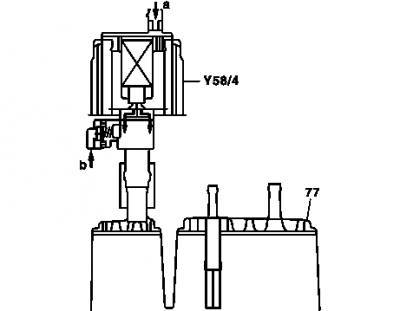

* 77 - Activated charcoal canister | * 77 - Activated charcoal canister | ||

* Y58/4 - Activated charcoal canister shutoff valve | |||

|[[File:W220_activated_charcoal_canister_with_orvr_location.jpg|400px]] | |||

|} | |||

=== Activated charcoal canister shutoff valve (USA) === | |||

<!-- | |||

GF47.30-P-4033L, Activated charcoal canister shutoff valve location/task/design/function, 10.7.96 | |||

MODEL 129 with ENGINE 104.943 /991 as of 1.8.96, 112.923 /943, 113.961, 119.982, 120.983 with CODE (494) USA version | |||

MODEL 140 with ENGINE 104.944 /994 as of 1.8.96, 119.981 /980, 120.982 with CODE (494) USA version | |||

MODEL 163 with ENGINE 112.942 /970, 113.942 /965 with CODE (494) USA version | |||

MODEL 170 with ENGINE 111.946 as of 1.6.98, 111.943 /973 /983, 112.947 with CODE (494) USA version | |||

MODEL 202 with ENGINE 104.941 as of 1.8.96, 111.921 as of 1.9.98, 111.974, 111.975 as of 1.8.96, 111.944 /945, 112.910 /920 with CODE (494) USA version | |||

MODEL 203 with ENGINE 112.912 /916 /946 /953 with CODE (494) USA version up to Model Year 8 | |||

MODEL 208 with ENGINE 111.944 /975, 112.940, 113.943 with CODE (494) USA version | |||

MODEL 209 with ENGINE 112.912 /955, 113.968 with CODE (494) USA version | |||

MODEL 210 with ENGINE 104.995, 112.911 /914 /921 /941, 113.940, 119.985 /980 with CODE (494) USA version | |||

MODEL 215 with ENGINE 113.960, 137.970 with CODE (494) USA version | |||

MODEL 220 with ENGINE 112.944 /972 /975, 113.941 /948 /960 /966, 137.970 with CODE (494) USA version | |||

MODEL 230 with ENGINE 112.973, 113.963 with CODE (494) USA version up to Model Year 8 | |||

MODEL 211 with ENGINE 112.913 /917 /949 /954, 113.967 /969 with CODE (494) USA version | |||

--> | |||

{| | |||

| | |||

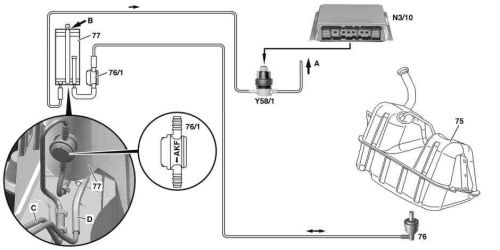

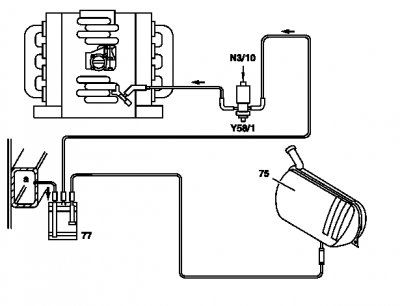

Shown in the design of model 210: | |||

* 77 - Activated charcoal canister | |||

* Y58/4 - Activated charcoal canister shutoff valve | |||

* A - Ventilation via the shutoff valve | |||

* B - Ventilation via the safety valve | |||

|[[File:W220_activated_charcoal_canister_shutoff_valve.png|400px]] | |||

|} | |||

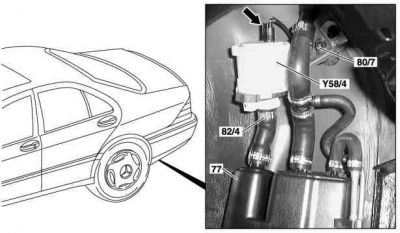

The task of the activated charcoal canister shutoff valve is to close the ventilation of the activated charcoal canister for a leakage test of the fuel system. | |||

The shutoff valve contains a solenoid which closes the valve when energizing. Additionally a mechanical safety valve is installed. | |||

The shutoff valve is located on the top at the vent connection of the activated charcoal canister. | |||

<!-- GF47.30-P-4033-01M, Activated charcoal canister shutoff valve position --> | |||

{| | |||

| | |||

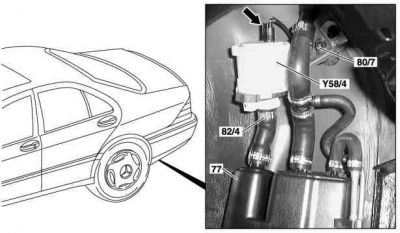

* 77 - Activated charcoal canister | |||

* 80/7 - Plastic nuts | |||

* 82/4 - Hose clamp | |||

* Y58/4 - Activated charcoal canister shutoff valve | * Y58/4 - Activated charcoal canister shutoff valve | ||

|[[File:W220_activated_charcoal_canister_with_orvr_location.jpg|400px]] | |[[File:W220_activated_charcoal_canister_with_orvr_location.jpg|400px]] | ||

Revision as of 07:50, 29 September 2021

The Evaporative Emission Control System (EVAP) is used to prevent gasoline vapors from escaping into the atmosphere from the fuel tank and fuel system at all times.

A typical system consists of the fuel tank, an EVAP vapor storage canister full of charcoal, valves, hoses and a sealed fuel tank gas cap. The EVAP system is designed to stop fuel system fumes from leaking directly into the atmosphere. Vent lines from the fuel tank pass vapors to the vapor canister, where they are trapped and stored until the engine is started. When the engine is warm and the vehicle is going down the road, the PCM then opens a purge valve allowing the vapors to be drawn from the storage canister into the intake manifold. The fuel vapors are then burned in the engine along with the air/fuel mixture.

Fuel evaporation control system function

|

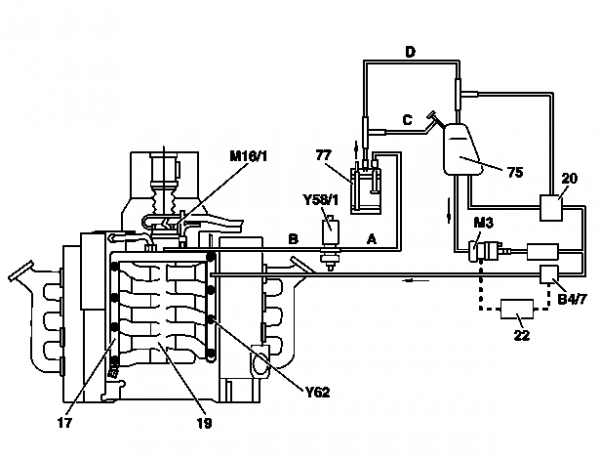

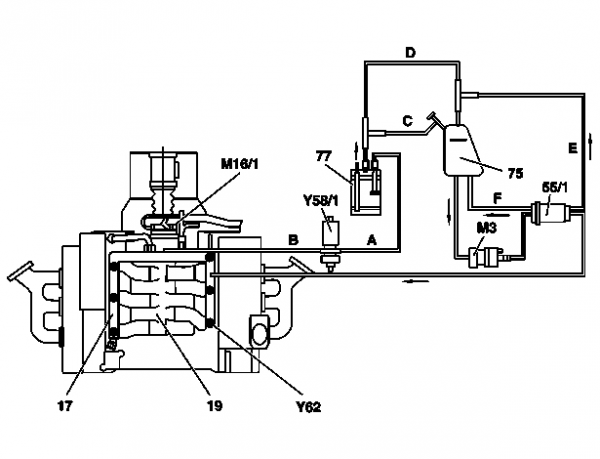

Shown on engine 119

|

|

The fuel evaporation control system prevents fuel vapors escaping to atmosphere. This is done by storing the fuel vapors temporarily in the activated charcoal canister.

When the engine is running, the fuel vapors stored in the activated charcoal canister are drawn off through the purge control valve and combusted in the engine. The activated charcoal canister is purged (re-generated) at:

- Coolant temperature > 70 °C

- Blocking time after engine start elapsed, approx. 2 minutes

- Engine not in deceleration mode

The purge quantity is controlled by the ME-SFI control unit operating the purge control valve. The purge quantity is determined by constantly opening and closing the purge control valve for on and off periods of various lengths.

The idle speed control prevents changes in engine speed resulting from purging. A richer or leaner fuel-air mixture is produced in line with the charge of the activated charcoal canister with fuel vapors.

Air admission to fuel tank. Air is admitted through the activated charcoal canister. This is done through the activated charcoal canister, whereby air is drawn out of the vent/breather line or fuel vapors are drawn from the activated charcoal canister into the fuel tank.

Air release from fuel tank. The fuel tank is vented through the activated charcoal canister. The fuel vapors flow to the activated charcoal canister, where they are stored or drawn into the intake manifold in case of simultaneous regeneration.

Vent valve. On vehicles fitted with a vent valve the fuel tank is vented from a pressure of 30 to 50 mbar, and air admitted at a vacuum of 1 to 16 mbar. In addition, this prevents overfilling the fuel tank.

USA as of MY 98. During refueling the fuel vapors are collected at the filler neck and passed to the activated charcoal filter (ORVR = Onboard Refueling Vapor Recovery). Large activated charcoal canister.

Engines with charging (compressor or turbocharger). A check valve in the purge line prevents the boost pressure building up toward the activated charcoal canister.

Model 215 from chassis no. A046659 (approx. 23.3.05), without USA and model 220 from chassis no. 469233 (ca. 23.3.05), without USA with ski bag (Code 282) or cooling compartment in rear backrest (Code 308) or with retrofitted additional vent valve (76/1):

The additional vent valve (76/1) prevents the vacuum from the intake manifold passing over the activated charcoal canister through to the fuel tank for enabled purging. For this purpose, the valve closes as soon as a membrane is pressurized with vacuum pressure from the activated charcoal canister. If excess pressure or vacuum pressure affects the other valve connection, it opens immediately. This means aeration/venting of the fuel tank is then possible in an unlimited fashion via the standard vent valve (76).

Pay attention to the installation position of the vent valve (76/1). Check aeration at the activated charcoal canister for contamination (e.g. dust, spider's webs).

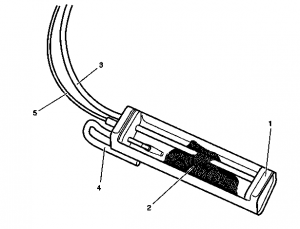

Activated charcoal canister

The task of the activated charcoal canister is ventilation and deventilation of the fuel tank and storing the fuel vapors temporarily for subsequent purging.

The hausing of the activated charcoal canister is filled with activated charcoal granulate, divided into different chambers by intermediate walls in order to achieve optimal flow through the activated charcoal. USA with ORVR: Quantities of around 2.7 to 3.5 l.

The fuel vapors released from the fuel tank (USA with ORVR or when refueling) are bonded to the activated charcoal. When purging is activated, they are drawn in by the engine and combusted. The activated charcoal is completely regenerated in the ideal case. The ventilation and deventilation of the fuel tank takes place over the activated charcoal canister.

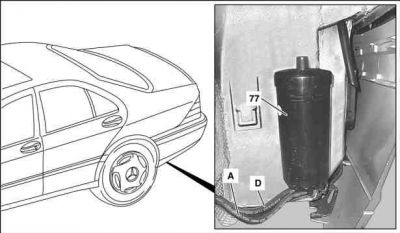

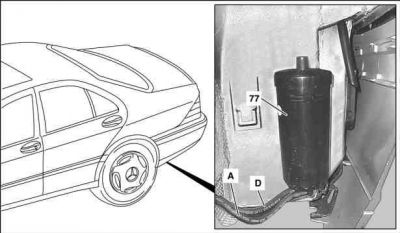

The activated charcoal canister is located at the rear in the rear left wheelhouse.

|

|

|

USA with ORVR:

|

|

Activated charcoal canister shutoff valve (USA)

|

Shown in the design of model 210:

|

|

The task of the activated charcoal canister shutoff valve is to close the ventilation of the activated charcoal canister for a leakage test of the fuel system.

The shutoff valve contains a solenoid which closes the valve when energizing. Additionally a mechanical safety valve is installed.

The shutoff valve is located on the top at the vent connection of the activated charcoal canister.

|

|

Parts

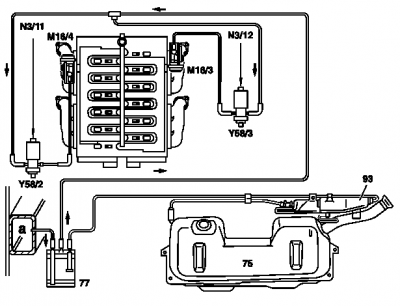

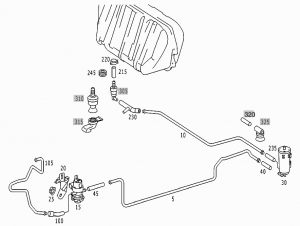

Connection diagram for evaporative emission control system (M113)

Connection diagram for evaporative emission control system (M112)

Remove/install activated charcoal canister

|

Shown on MODEL 220

|

|

- Raise vehicle.

- Remove rear left wheelhousing liner

- Detach activated charcoal canister - purge control valve line (A) and vent valve line - activated charcoal canister to fuel tank (D) at activated charcoal canister (77)

- Remove activated charcoal canister (77). Lift up and out.

- Install in the reverse order