Crankshaft position sensor: Difference between revisions

No edit summary |

|||

| Line 99: | Line 99: | ||

|} | |} | ||

==DIY | ==DIY Tests== | ||

CPS can be tested by measuring its resistance and checking whether it generates voltage. | CPS can be tested by measuring its resistance and checking whether it generates voltage. | ||

Revision as of 20:08, 19 November 2016

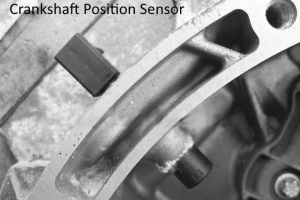

Description

|

|

|

The crankshaft position sensor (CPS) is located on driver’s side, towards the rear of engine. Back of engine, near the firewall. It monitors the engine crankshaft position and speed and is one of the most important input sensors that is used by the Engine Control Unit (ECU). If the crankshaft position sensor fails, it will not send information about the position of the crankshaft and speed of the engine RPMs to the ECU. As a result, the ECU doesn't know when to send the spark plugs and how to adjust the fuel mixture. This can cause your car to stall or hesitate to start.

Problems with the Crankshaft Position Sensor on Mercedes-Benz cars are fairly common. If you have been experiencing stalling or no start conditions, a failed crankshaft position sensor is often the problem.

Symptoms of fault:

- The engine may crank, but it will not start (starting problems are initially random, but more frequent when the engine is hot).

- The engine cranks longer in order to get it to start.

- Car runs for a short time, or until it gets warm and then it dies.

- Poor acceleration, engine vibrations, poor throttle response, bad fuel economy.

- Impact on transmission shifting. In some cases, it can cause the transmission to go into limp mode.

Hint: If you are stuck on a parking lot and the car will not start, let the car cool down at least 30 minutes and then try again. What happens is when the car gets hot, the sensor's resistance goes open circuit, thus the car dies. Now since the sensor is still hot, the sensor is still open circuit, but once it cools off, the resistance comes back into spec, thus the car starts.

If your check engine light is on, then your ECU has recorded some sort of trouble code. You can check these codes with a diagnostic scan tool. Codes between P0335 and P0339 correspond to crankshaft sensor problems. This is probably the most straightforward and the most certain way to test for and identify a crankshaft sensor problem. Unfortunately, the crankshaft sensor is usually pretty far gone by the time that the check engine light is on. You might already be experiencing crankshaft sensor problems before the ECU has noted any sign of trouble.

| Error Code | Description |

|---|---|

| P0335 | Crankshaft Position Sensor A Circuit Malfunction (L5) |

| P0336 | Crankshaft Position Sensor A Circuit Range/Performance |

| P0337 | Crankshaft Position Sensor A Circuit Low Input |

| P0338 | Crankshaft Position Sensor A Circuit High Input |

| P0339 | Crankshaft Position Sensor A Circuit Intermittent |

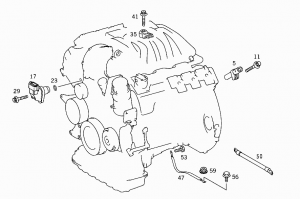

Parts

W220 uses magnetic impulse triggering sensor with two wires.

- CPS OE A0031532728 (Replaced by A0031532828)

- CPS OE A0031532828 (~125EUR)

- CPS BOSCH part 0261210170 (~50EUR)

- Screw N910142006001

- Pin bushing housing A1685453028

|

|

|

DIY Replacement

|

|

|

|

|

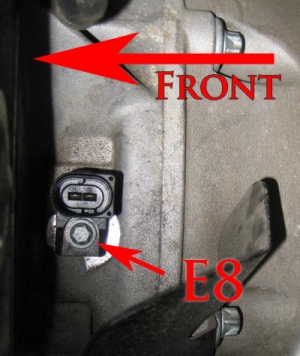

Tools needed:

- E8 torx 1/4 socket.

- Ratchet with 6-inch 1/4 extension.

Steps:

- Remove engine cover.

- Unplug the electrical connector from the CPS sensor.

- Remove bolt using E8 torx socket.

- Install in opposite order.

Note: If a heat shield is installed, there may be too small space for hand to fit. The way around it to not actually remove the connector, but just blindly remove the E8 torx bolt and use the connector and line to fish the CPS out.

DIY Tests

CPS can be tested by measuring its resistance and checking whether it generates voltage.

- You can remove the sensor, and then test the resistance. Attach one end of the multimeter to each wiring lead of the sensor. Resistance of zero means that the there is a short circuit. Infinite resistance means there is an open circuit. Either one of those readings indicates that the sensor is not working. For any other reading, check it against the manufacturer's specifications. If your reading is not close to the recommended resistance, then you should replace the sensor.

- Another way to test the crankshaft sensor with a multimeter is by checking the output voltage with the engine cranking. You will need an assistant to do this. Be very careful around moving parts as you do this. Probe the wiring connectors and measure the output voltage in AC millivolts. Typically, this reading is around 200 millivolts, but this can vary from vehicle to vehicle. Check the manufacturer's specifications. If there is no output voltage, then, obviously, your sensor is not working.

Resources

- http://www.doityourself.com/stry/warning-signs-of-a-bad-crankshaft-position-sensor

- http://www.mercedesmedic.com/crank-shaft-position-sensor/

- https://www.1aauto.com/content/articles/crank-sensor-testing

- http://www.benzworld.org/forums/w220-s-class/1307031-2000-s500-problem-please-help.html

- http://www.benzworld.org/forums/w220-s-class/1496096-diy-cps-write-up.html

- http://www.benzworld.org/forums/w220-s-class/1635675-how-replace-cps-crankshaft-position-sensor.html

- http://mbworld.org/forums/s-class-w220/326637-how-replace-crank-position-sensor-cps-s500.html