Front axle: Difference between revisions

(→DIY Fitted Bolt: updated photo) |

|||

| Line 321: | Line 321: | ||

For more flexible suspention adjustment a fitted bolt A2203330171 can be installed. | For more flexible suspention adjustment a fitted bolt A2203330171 can be installed. | ||

[[File:W220_A2203330171_fitted_bolt.jpg|thumb|none|Fitted bolt (A2203330171)]] | [[File:W220_A2203330171_fitted_bolt.jpg|thumb|none|Fitted bolt (A2203330171)]] | ||

=== Replace supporting joint === | |||

<!-- AR33.20-P-0440I | |||

MODEL 215 | |||

MODEL 220 (except 220.08 /18 /87) | |||

except CODE (979) Special protection version | |||

except CODE (Z07) Top protection | |||

25.2.98 --> | |||

{| | |||

| | |||

* 5 - Steering knuckle | |||

* 7 - Support joint | |||

|[[File:W220_Replace_supporting_joint_front_suspension.jpg]] | |||

|} | |||

# Remove steering knuckle (5) | |||

# Check supporting joint (7) | |||

# Press supporting joint (7) out of steering knuckle (5) | |||

# Install in the reverse order | |||

==Torque Specifications - Complete Front Axle/Suspension== | ==Torque Specifications - Complete Front Axle/Suspension== | ||

Revision as of 12:28, 28 September 2018

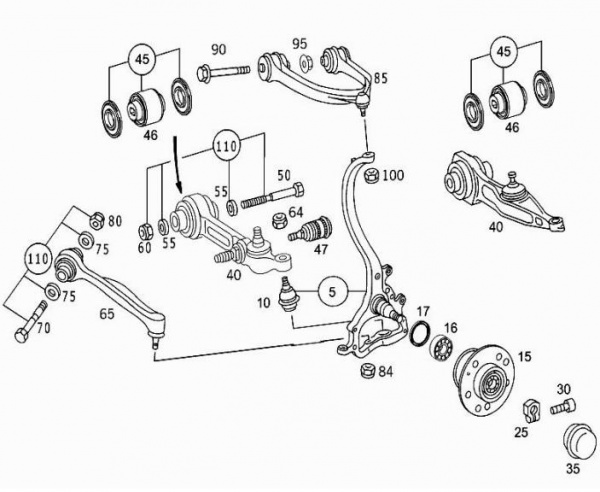

Description - Complete Front Axle/Suspension

Transverse Control Arm Top or Upper Control Arm Item 85 - Complete Front Axle/Suspension

Transverse Control Arm Top/Upper (also called Upper Control Arm (UCA)), Item 85 Right and Left.

Steering Knuckle Item 5 - Complete Front Axle/Suspension

Steering Knuckle (also Spindle or Hub) (Item 5)

Transverse Control Arm Lower or Lower Control Arm Item 40 - Complete Front Axle/Suspension

Transverse Control Arm Bottom/Lower (Lower Control Arm (LCA)) Item 40 Right and Left

Ball Joint Steering Knuckle to Lower Control Arm Item 10 - Complete Front Axle/Suspension

Ball Joint Steering Knuckle to Lower Control Arm (Item 10)

Strut Item 65 - Complete Front Axle/Suspension

Strut (also called Thrust Arm or Torque Strut) Item 65 Right and Left

Rod Torsion Bar Item 25 - Complete Front Axle/Suspension

Rod Torsion Bar (Sway Bar Link) Item 25 Right and Left

Part Numbers - Complete Front Axle/Suspension

| Item no. | Part number | Designation/description | Quantity |

|---|---|---|---|

| 5 | A 220 330 37 20 | STEERING KNUCKLE LEFT Code: -Z04 | 001 |

| 5 | A 220 330 37 20 | STEERING KNUCKLE RIGHT Code: -Z04 | 001 |

| 10 | A 220 333 07 27 | JOINT . LEFT | 001 |

| 10 | A 220 333 07 27 | JOINT . RIGHT | 001 |

| 15 | A 220 330 07 25 | FRONT WHEEL HUB WITH BEARING | 002 |

| 16 | A 002 980 65 02 | TAPERED ROLLER BEARING . WHEEL HUB, OUTSIDE. Code: -Z07 | 002 |

| 16 | A 140 981 03 05 | TAPERED ROLLER BEARING. WHEEL HUB, INSIDE. Code: -Z07 | 001 |

| 16 | A 140 981 03 05 | TAPERED ROLLER BEARING. WHEEL HUB, INSIDE | 001 |

| 17 | A 022 997 97 47 | SEAL RING. WHEEL HUB . Code: -Z07 | 001 |

| 17 | A 022 997 97 47 | SEAL RING. WHEEL HUB | 001 |

| 25 | A 116 334 03 72 | NUT FRONT WHEEL HUB TO STEERING KNUCKLE | 002 |

| 30 | N 000000 003358 | HEXALOBULAR BOLT FRONT WHEEL HUB TO STEERING KNUCKLE M6X25 | 002 |

| 35 | A 168 357 00 89 | PLUG FRONT WHEEL HUB TO STEERING KNUCKLE | 002 |

| 40 | A 220 330 89 07 | TRANSVERSE CONTROL ARM BOTTOM LEFT Code: -487-Z07 | 001 |

| 40 | A 220 330 90 07 | TRANSVERSE CONTROL ARM BOTTOM RIGHT Code: -487-Z07 | 001 |

| 45 | A 220 330 91 07 | TS SPRING LINK PARTS KIT LEFT AND RIGHT Code: -Z07 . [408] ONLY REPLACEABLE BY PAIRS | 002 |

| 46 | A 220 333 31 14 | BEARING SPRING CONTROL ARM . . Code: -Z07 | 002 |

| 47 | A 211 323 00 68 | JOINT. LEFT | 001 |

| 47 | A 211 323 00 68 | JOINT. RIGHT | 001 |

| 50 | A 220 333 00 71 | BOLT SPRING CONTROL ARM AT FRAME M14X1.5 | 002 |

| 50 | A 220 333 01 71 | FITTED BOLT FOR ADJUSTING WORK ONLY M14X1.5 | 002 |

| 55 | A 220 333 00 76 | SHIM SPRING CONTROL ARM AT FRAME | 004 |

| 60 | N 000000 003281 | HEXAGON NUT SPRING CONTROL ARM AT FRAME M14X1,5 | 002 |

| 64 | N 000000 003281 | HEXAGON NUT SPRING LINK ON SUPPORTING JOINT M14X1,5 | 002 |

| 65 | N 000000 003281 | STRUT LEFT | 001 |

| 65 | N 000000 003281 | STRUT RIGHT | 001 |

| 70 | A 220 333 00 71 | BOLT STRUT AT FRAME M14X1.5 | 002 |

| 70 | A 220 333 01 71 | FITTED BOLT FOR ADJUSTING WORK ONLY M14X1.5 | 002 |

| 75 | A 220 333 00 76 | SHIM STRUT AT FRAME | 004 |

| 80 | N 000000 003281 | HEXAGON NUT STRUT AT FRAME M14X1,5 | 002 |

| 84 | N 000000 003281 | HEXAGON NUT STRUT TO STEERING KNUCKLE M14X1,5 | 002 |

| 85 | A 220 330 93 07 | TRANSVERSE CONTROL ARM TOP, LEFT | 001 |

| 85 | A 220 330 94 07 | TRANSVERSE CONTROL ARM TOP, RIGHT | 001 |

| 90 | A 004 990 81 04 | BOLT UPPER CONTROL ARM TO FRAME M10X95 | 004 |

| 95 | N 913023 010002 | NUT UPPER CONTROL ARM TO FRAME M10 | 004 |

| 100 | N 910113 010000 | HEXAGON NUT UPPER TRANSVERSE CONTROL ARM TO STEERING KNUCKLE M10 | 002 |

| 110 | A 000 330 00 18 | TS BOLT PARTS KIT FOR ADJUSTING WORK ONLY | 004 |

- Front end lower shock mount control arms (ABC models only) are part number 215 330 07 07.

- FL thrust arm (Lemfoerder): W0133-1717286

- FR thrust arm (Lemfoerder): W0133-160157.

- All of those come with new ball joints installed.

Issues - Complete Front Axle/Suspension

Common issues with the Complete Front Axle/Suspension are;

- Front tyre/s wearing unevenly.

- Front suspension making a creaking sound at low speed indicating possible ball joint failure.

- Looseness indicated by excess movement in ball joint/s (Item 100) ie it feels worn and not firm in its socket.

- Cracks in the control arm (Item 85) bushings and ball joints.

If you experience any of the above issues, the following parts are the ones that often need replacing due to wear after about 130,000 Km (80,000 miles).

The front rear lower control arms (shock mount control arms) are not a "must replace" item. If your car has higher miles (80k+), then it would be a good idea to replace them as well. The outer end of the arm can be quite tricky to force off the ball joint at the knuckle (spindle).

The thrust arms (torque arms) wear out faster, as they take the brunt force of the vehicle under braking. Once you pull out the thrust arms, take a look at the chassis side joint. If the rubber has clearly failed (lots of cracks), then it may be a good idea to change the shock control arms as well.

- Item 85 Transverse Control Arm Top (Upper Control Arm (UCA)).

- Item 40 Transverse Control Arm Bottom/Lower (Lower Control Arm (LCA))

- Rear View of Transverse Control Arm Bottom Lower Item 40

- Front View of Transverse Control Arm Bottom Lower Item 40

- Item 65 Strut (Thrust Arm or Torque Strut)

- Item 10 Joint (Ball Joint)

- Item 25 Rod Torsion Bar (Sway Bar Link)

Special Tools Required - Complete Front Axle/Suspension

Tips for DIY Repairs - Complete Front Axle/Suspension

- Make absolutely certain that the car is properly and safely supported. You will be pulling and pushing hard on the car while you are under it.

- atmshsr says “On a recommendation of a machinist, I kept all new parts in the freezer for a few days to shrink them before assembly because the fit tolerances are so tight, and did not remove each part until just prior to installing the part.“

- Make sure to soak all the bolt/nuts a few hours before you start work with PB blaster or Penetrene.

- BenzWorld Member Tip: In hindsight, I should have replaced both the Strut (also called Thrust Arm or Torque Strut) Item 65, and control arms

- Transverse Control Arm Top/Upper (also called Upper Control Arm (UCA)), Item 85

- Transverse Control Arm Bottom/Lower (Lower Control Arm (LCA)), Item 40

at the same time because they have similar bushings that undergo the same service environment. Additionally, if I had to do it over, I would do both control arms and completely remove the Steering Knuckle (also Spindle or Hub) (Item 5) for easier access to a ball joint and ease reinstallation.

- Take your time disconnecting and reconnecting any of the electrical connectors in the area - its easy to mess these up. Use some masking tape to mark the connections.

- Once the car is jacked up and the wheels removed, release the air pressure on the top of the shock. With the key off, and the vehicle raised up, crack open the fitting at the top of the airmatic strut. Be careful not to allow any dirt in the system. Once everything is connected back up it will just fill back up once the car is turned on.

- When using the Ball Joint Separator tool, tighten it, walk away. Come back a few hours later, tighten it a little more and walkway. Repeat the steps. The ball joint normally breaks loose due to tension. If you are lucky it will let go after about 30-40 minutes.

- Use a hot air dryer on each stuck nut for about five mins each and they come out easy, the heat breaks down the lock-tight bond.

- The 5mm Alan has blue Loctite from the factory and normally requires an impact grade driver to remove. If you end up rounding the Alan out, (which can easily happen) then the drill must come out and carefully drill out the set screw. Here's how to remove them using a a miniature butane torch [1]

- Good website for more tips on how to get set screws out and ball joints separated. [2]

- If you are doing this DIY with a jack and stands the easiest way is to remove the Steering Knuckle (also Spindle or Hub) (Item 5) with the arms attached after removing the brake caliper. Just remove the tie rod end from the knuckle then disconnect the strut from the control arm, followed by releasing the upper control arm from the knuckle then control arms from the chassis. This way it is a lot easier to remove the arms from the knuckle on a work-bench.

- Removing the Steering Knuckle (also Spindle or Hub) (Item 5) as a first step really frees up the area for further work. Please note that it is essential to use a 5mm hex key to hold the center stud from turning when removing the 21mm nut at the wheel hub. A long handled key with a Blackhawk brand 21mm ratcheting closed end wrench is useful.

- After strut replacement the correct procedure is to do a ride height adjustment using M-B's Star Diagnosis System (SDS) and then a four wheel alignment, failure to do so will result in bad tyre wear.

- As long as you do not extend or shorten the Tie-Rod, from the inner tie rod, after it is disconnected from the steering knuckle, there is no need for alignment. So, leave the Tie-rod alone after you separate it from the knuckle.

- When you are done with repair, put the wheels on and carefully lower the vehicle back down with the weight of the car resting on the suspension. THEN, tighten the airmatic fittings and turn the car on. The vehicle should return back to its normal height. Only tighten the lower control arm bolt to the vehicle fitting with the vehicle weight fully on the wheels (or lower the car onto car ramps), as this will prevent the rubber from being torqued and tearing in the lower control arm.

DIY Repairs - Complete Front Axle/Suspension

Before starting any DIY repairs make sure to read the Tips section above.

DIY How To Remove Ball Joints Using a Ball Joint Separater Tool

http://www.benzworld.org/forums/w220-s-class/1519699-w220-ball-joint-replacement-diy-tutorial.html

DIY How To Remove Ball Joints Using a Ball Peen Hammer

DIY How to Replace Front Lower Control Arm Bushings

http://www.benzworld.org/forums/w220-s-class/1810897-02-s500-lower-control-arm-bushings.html

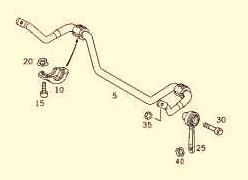

DIY Fitted Bolt

The Transverse Control Arm and Thrust Arm uses standard bolt A2203330071 fitted at factory. After an accident or through years of heavy use the chassis of the vehicle deforms which causes problems for suspension geometry adjustment. For more flexible suspention adjustment a fitted bolt A2203330171 can be installed.

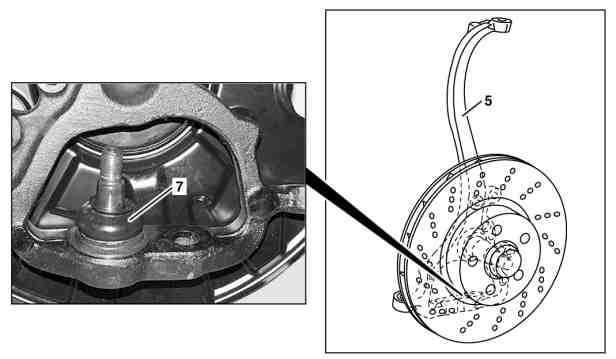

Replace supporting joint

|

|

- Remove steering knuckle (5)

- Check supporting joint (7)

- Press supporting joint (7) out of steering knuckle (5)

- Install in the reverse order

Torque Specifications - Complete Front Axle/Suspension

Torque specs for a 2004 S600 (with ABC) are as follows from WIS. According to WIS, these values apply to all W220 and 215 cars with ABC. If your 2003 S600 has ABC, then it is assumed these apply. Do double check though as we will not be held liable for any damages.

- Tie rod to steering knuckle (spindle) is 50NM then 60 degrees

- Torque arm (thrust arm) to chassis 80NM then 120 degrees

- Torque arm (thrust arm) to knuckle (spindle) 50NM then 60 degrees

- Upper control arm to knuckle (spindle): 20NM then 90 degrees

- Lower control arm (aka spring control arm-front rear lower control arm that shock mounts) to knuckle (spindle) 50NM then 60 degrees

- Lower control arm (aka spring control arm-front rear lower control arm that shock mounts) to chassis 80NM then 120 degrees

NOTE: all must be torqued under load at the correct ride height (ie the vehicle on the ground). Since most don't have a four post lift, you'll need to take careful measurements, then support each corner accordingly before fully tightening. You will also need four eccentric bolts if you wish to have a proper wheel alignment done afterwards. Eccentric bolt kits are # W0133-1630584