Crankcase ventilation cylinder head cover: Difference between revisions

(Loctite product description added.) |

|||

| Line 28: | Line 28: | ||

==== Sealant ==== | ==== Sealant ==== | ||

* A003989982010 (OE) - EUR 26 | * A003989982010 50ml (OE) - EUR 26 | ||

* Loctite 5970 (OEM) - EUR 18 | * Loctite 5970 300ml (OEM) - EUR 18 | ||

* Elring Dirko - EUR 5 | * Elring Dirko 70ml - EUR 5 | ||

{| | {| | ||

|[[File:A003989982010_sealant_compound_50ml.jpg|thumb|none|A003989982010 sealing compound 50ml]] | |[[File:A003989982010_sealant_compound_50ml.jpg|thumb|none|A003989982010 sealing compound 50ml]] | ||

|[[File: | |[[File:Loctite_SI_5970_sealant_300ml.jpg|thumb|none|Loctite 5970 sealing compound 300ml]] | ||

|[[File:Elring_dirko_sealant_black.jpg|thumb|none|Elring Dirko sealant 70ml]] | |[[File:Elring_dirko_sealant_black.jpg|thumb|none|Elring Dirko sealant 70ml]] | ||

|} | |} | ||

| Line 41: | Line 41: | ||

The correct sealant must be used and it must be made sure that the sealing surfaces are ABSOLUTELY clean of any dirt, oil, or moisture BEFORE applying the new CORRECT sealant. | The correct sealant must be used and it must be made sure that the sealing surfaces are ABSOLUTELY clean of any dirt, oil, or moisture BEFORE applying the new CORRECT sealant. | ||

{| | |||

| | |||

* Loctite 7200 (EUR 15) 400 ml spray - Parts Cleaner - gasket remover. Removes gasket sealants in 10-15 minutes. | * Loctite 7200 (EUR 15) 400 ml spray - Parts Cleaner - gasket remover. Removes gasket sealants in 10-15 minutes. | ||

Removes all types of chemical gaskets eliminating excessive scraping. Softens chemical gaskets quickly. Will not run, even on vertical surfaces. Removes cured chemical gaskets by softening the gasket material on the flanges, avoiding excessive scraping. Dissolves also sealants, adhesives, carbon deposits, and dried oils. Once applied the product foams, preventing run off from the desired location. Application: Protect painted surfaces, as Gasket Remover attacks the paint. Hold can upright and spray from distance of about 20 - 30 cm onto the flange or surface. Allow 10 - 15 minutes to soften the gasket, for silicone gaskets 30 minutes are necessary. Remove gasket with a soft scraper. Wipe the surface with a rag. Repeat procedure if it is necessary. | |||

|[[File:Loctite-sf-7200.jpg|100px]] | |||

|} | |||

{| | |||

| | |||

* Loctite 7063 (EUR 12) 400 ml spray - Parts Cleaner - general purpose. For use prior to bonding and sealing applications. Leaves no residue. | * Loctite 7063 (EUR 12) 400 ml spray - Parts Cleaner - general purpose. For use prior to bonding and sealing applications. Leaves no residue. | ||

** A001986717110 (EUR 10) 150ml spray | ** A001986717110 (EUR 10) 150ml spray | ||

Excellent for surface preparation. High cleaning power. Rapid flash off. Use to prepare surfaces to be bonded. The product flashes off very quickly and it allows cleaning directly prior to adhesive/sealant application. It is non-corrosive and non toxic. Application: Spray a sufficient amount of product on the surface to be cleaned and wipe while still wet to ensure heavy contamination and excess solvent is removed. | |||

|[[File:Loctite-sf-7063.jpg|100px]] | |[[File:Loctite-sf-7063.jpg|100px]] | ||

|} | |} | ||

| Line 114: | Line 120: | ||

Work instructions: | Work instructions: | ||

* Aluminum bolts (1). Installation: Install new bolts. | * Aluminum bolts (1). Installation: Install new bolts. | ||

* Clean. When cylinder head covers are installed, cover oil ducts with rags. Do not use any sharp-edged tools or abrasive paper as this will damage the sealing surfaces. Oil channels clogged with sealant will damage the engine. Cleaning materials: Loctite 7200 | * Clean. When cylinder head covers are installed, cover oil ducts with rags. Do not use any sharp-edged tools or abrasive paper as this will damage the sealing surfaces. Oil channels clogged with sealant will damage the engine. Cleaning materials: Loctite 7200 and Loctite 7063 cleaning spray 150 ml (A001986717110). | ||

* Sealant. Apply a 2.0 mm thick bead of sealant (A), observing the bolt holes (arrow). Do not spread the silicone bead. Process sealant within 10 minutes. To avoid leaks, use only the silicone sealant specified in the repair materials - Loctite 5970 sealant (A0039899820)! | * Sealant. Apply a 2.0 mm thick bead of sealant (A), observing the bolt holes (arrow). Do not spread the silicone bead. Process sealant within 10 minutes. To avoid leaks, use only the silicone sealant specified in the repair materials - Loctite 5970 sealant (A0039899820)! | ||

Revision as of 18:14, 4 April 2020

|

|

Crankcase ventilation

Crankcase ventilation cover (engine breather cover) is a very common source for oil leaks on Mercedes M112 V6 and M113 V8 engines. When the oil gets on exhaust manifold, it creates smell that can be felt even in the cabin. Resealing the cover is easy way to fix oil leak.

For all M112 and M113 gas engines with leaking breather chamber covers on top of engine If you own a 1998 to 2006 Mercedes with a V6 (M112) or a V8 (M113) engine this is one job you will have to deal with at some point. Just pull the top cover off your engine and look. Even cars with low mileage may have oil seeping out the breather covers on the top of the heads. Doing a proper reseal on these covers is not hard but it is tedious if you don't want them to leak again. This is one job if you want it done right you should consider doing it yoursel!!!

Parts

Several parts will be needed for replacement. Several resealing kits are available:

- https://mercedessource.com/store/1998-2006-v6-and-v8-engine-breather-cover-oil-leak-fix-kit

- https://www.fcpeuro.com/products/mercedes-breather-cover-reseal-kit-m112-m113-oem-m112bcvr

Below we provide part numbers for each part separately.

Bolts

The 5 original aluminium bolts will have to be replaced with updated stainless steel ones as the old will snap if trying to re-use them. The replacement stainless steel bolts have a 5 mm hex head rather than a torx head.

The bolts correspond to M5x18 specification and their part number is N000000004436 (~2 EUR/piece).

Sealant

- A003989982010 50ml (OE) - EUR 26

- Loctite 5970 300ml (OEM) - EUR 18

- Elring Dirko 70ml - EUR 5

|

|

|

Cleaner

The correct sealant must be used and it must be made sure that the sealing surfaces are ABSOLUTELY clean of any dirt, oil, or moisture BEFORE applying the new CORRECT sealant.

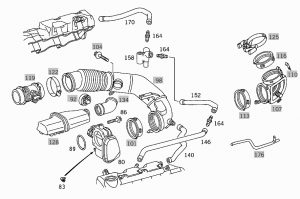

Breather hoses

Over time the rubber hoses get hard and cannot be removed without breaking. It is therefore recommended to replace 4 hoses and 3 connectors.

Engine 112 and 113 (S350/S500):

|

|

|

|

|

|

|

|

|

|

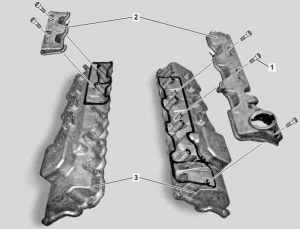

Remove/install cover for crankcase ventilation (WIS instruction)

ENGINES 112, 113

Shown on engine 113:

|

|

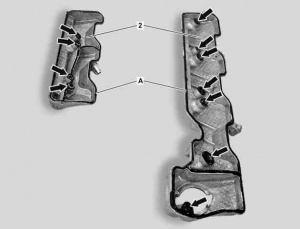

Sealant path - Shown on engine 113:

|

|

Work instructions:

- Aluminum bolts (1). Installation: Install new bolts.

- Clean. When cylinder head covers are installed, cover oil ducts with rags. Do not use any sharp-edged tools or abrasive paper as this will damage the sealing surfaces. Oil channels clogged with sealant will damage the engine. Cleaning materials: Loctite 7200 and Loctite 7063 cleaning spray 150 ml (A001986717110).

- Sealant. Apply a 2.0 mm thick bead of sealant (A), observing the bolt holes (arrow). Do not spread the silicone bead. Process sealant within 10 minutes. To avoid leaks, use only the silicone sealant specified in the repair materials - Loctite 5970 sealant (A0039899820)!

Torque specification:

- Bolt, crankcase ventilation cover to the cylinder head valve cover: 4 Nm (Engine 112 and 113)

Remove/install cover for crankcase ventilation (alternative instruction)

Process:

- Removing the cover from the engine

- Inspecting the sealing surfaces for leaks

- Initial cleaning for the dirt and old sealant

- 2nd level cleaning of the oil and grease

- Tools and supplies to use to avoid damaging the surface of the magnesium parts

- 3rd level and final deep cleaning

- Replacement of the original aluminum bolts

- Cleaning the valve cover long bolts

- Proper application of the sealant

- Reason for quick assembly

- Using a torque wrench for final tightening of the bolts

- Inspection and final wrap up

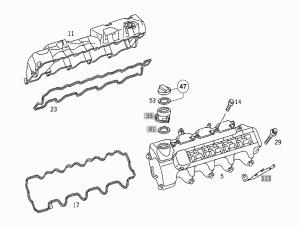

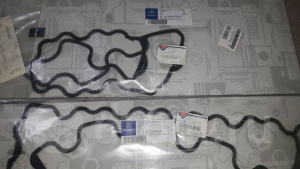

Cylinder head cover

Cylinder head cover gaskets

Engine 112 (S350):

- A1120160221 Cylinder head cover gasket (left) - EUR 20

- A1120160321 Cylinder head cover gasket (right) - EUR 20

Engine 113 (S500):

- A1120160221 Cylinder head cover gasket (left) - EUR 22

- A1120160321 Cylinder head cover gasket (right) - EUR 22

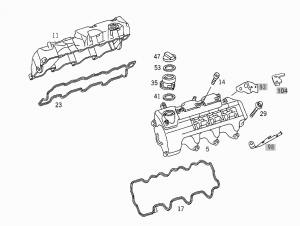

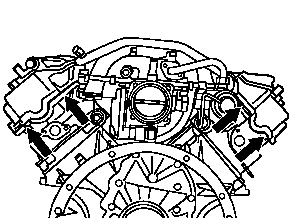

Remove/install cylinder head cover (WIS instruction)

Remove/install:

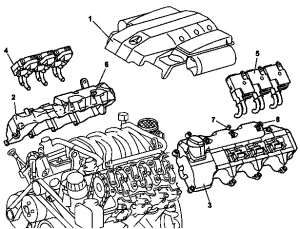

- Remove engine trim panel with integrated air filter (1). Unclip covering on front side of engine. Remove air filter by pulling vertically up and off the cylinder head covers.

- Remove air filter (Model 215.374, 220.074/174)

- Unscrew guide tube for the automatic transmission oil dipstick

- Detach right ignition coils (4), left ignition coils (5) on right cylinder head cover (2) and left cylinder head cover (3). Except engines 112.911/914/915/917/954, Engine 113.969.

- Disconnect spark plug connectors. Installation: Observe marking for spark plug connectors on the cylinder head covers and ignition coils.

- Pull off vent hoses on right connector (6) and on left connector (7) of the right cylinder head cover (2) and left cylinder head cover (3).

- Pull off engine vent hose on left connector (8) of left cylinder head cover (3).

- Disconnect fuel line at fuel rail. Only on vehicles with rigid fuel line and: Model 211.061/065/070/076/276, Model 215.374, Model 220.074, Model 230.474/475. Release fuel pressure through service valve!

- Remove right cylinder head cover (2) and left cylinder head cover (3). Installation: Check cylinder head covers for leaks, see: Ensure cylinder head cover gasket is correctly installed.

- Install in the reverse order

- Check for leaks with engine running

Torque specifications:

- Cylinder head cover bolt: 9 Nm (Engine 112 and 113)

- Bolt, ignition coils to cylinder head cover: 8 Nm (Engine 112 and 113)

- Fuel feed line to fuel distributor: 38 Nm (Engine 112 except 112.945/951/960/961)

- Fuel feed line to fuel distributor: 38 Nm (Engine 112.945)

- Fuel feed line to fuel distributor: 35 Nm (Engine 112.960/961 AMG)

- Fuel feed line to fuel distributor: 38 Nm (Engine 113.940/941/942/943/944/945/946/948/960/961/962/963/964/965/966/967/968/969/971/980/981/982/984/986/988)

- Fuel feed line to fuel distributor: 38 Nm (Engine 113.987)

- Fuel feed line to fuel distributor: 38 Nm (Engine 113.990/991)

- Fuel feed line to fuel distributor: 38 Nm (Engine 113.992/993/995)

Ensure gasket of cylinder head cover is correctly installed:

|

|