Headlamp cleaning system: Difference between revisions

No edit summary |

(Headlamp cleaning system initial) |

||

| Line 1: | Line 1: | ||

== Headlamp cleaning system (HCS) == | |||

The purpose of headlamp cleaning system (HCS) is cleaning headlamp lenses. | |||

<!-- GF82.15-P-0002-03S Headlamp cleaning system (HCS), location of components --> | |||

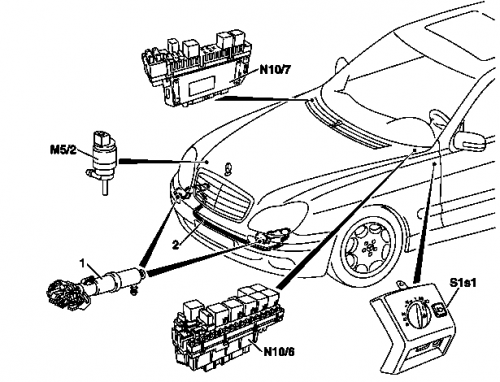

Location of components: | |||

{| | |||

|[[File:W220_headlamp_cleaning_system_components.png|500px]] | |||

|Illustrated on model 220: | |||

* 1 - Telescoping nozzle | |||

* 2 - Washing water hose for headlamp cleaning system | |||

* M5/2 - Headlamp cleaning system pump | |||

* N10/6 - Left front SAM control module | |||

* N10/7 - Right front SAM control module | |||

* S1s1 - Headlamp cleaning system switch | |||

|} | |||

<!-- GF82.15-P-0002-04S Headlamp cleaning system (HCS), interlinkage of components --> | |||

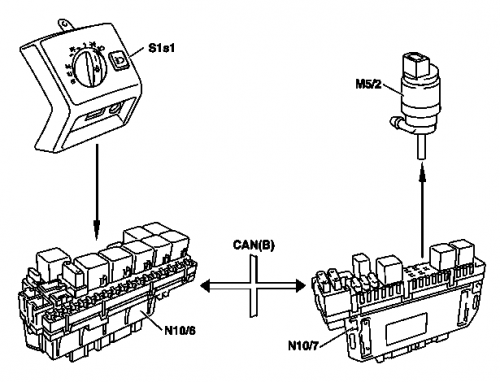

{| | |||

|[[File:W220_headlamp_cleaning_system_interlinkage.png|500px]] | |||

| | |||

Interlinkagae of components: | |||

* CAN (B) - CAN (passenger compartment) | |||

* M5/2 - Headlamp cleaning system pump | |||

* N10/6 - Left front SAM control module | |||

* N10/7 - Right front SAM control module | |||

* S1s1 - Headlamp cleaning system switch | |||

|} | |||

<!-- GF82.15-P-0002S Headlamp cleaning system (HCS), function | |||

MODEL 215, 220 with CODE (600a) Headlamp cleaning system --> | |||

Function precondition: | |||

* Circuit 15 ON | |||

'''Manual operation''' | |||

* The headlamp cleaning system (HCS) is switched on by pressing the HCS switch (S1s1). | |||

* This connects the corresponding input of the left front SAM control unit (N10/6), which reads in the signal of the HCS switch (S1s1), to ground. | |||

* The left front SAM control unit (N10/6) places the switch-on pulse onto the class B Controller Area Network bus (interior) (CAN-B) as a message. | |||

* The right front SAM control unit (N10/7) reads in this message and connects circuit 15 to the HCS pump (M5/2) for a switch-on time of approx. 1 s via an electronic switch (transistor). | |||

* The HCS pump (M5/2) builds up water pressure in the line. | |||

* The water pressure acts against the return springs in the telescopic nozzle. | |||

* Before the telescopic nozzles extend, spraying water on the headlamp lenses. | |||

* After expiration of the switch-on time, the pressure in the water line decreases and the telescopic nozzles are retracted to their initial position by the spring force. | |||

Pressing the HCS switch (S1s1) again when a headlamp cleaning cycle is being performed has no effect. | |||

Another headlamp cleaning cycle cannot be activated until the preceding one has completed. | |||

'''Automatic operation (in vehicles as of 1.6.04)''' | |||

After the windshield washer system has been operated 15 times the HCS pump (M5/2) is actuated automatically. | |||

This automatic control is performed by the right front SAM control unit (N10/7). | |||

Function: For each actuation of the windshield washer fluid pump (M5/1) the internal counter in the right front SAM control unit (N10/7) is incremented by 1 until it reaches the value "15", then the HCS pump (M5/2) is actuated and the counter is reset to "0". | |||

The internal counter is always reset to "0" whith circuit 15 off. | |||

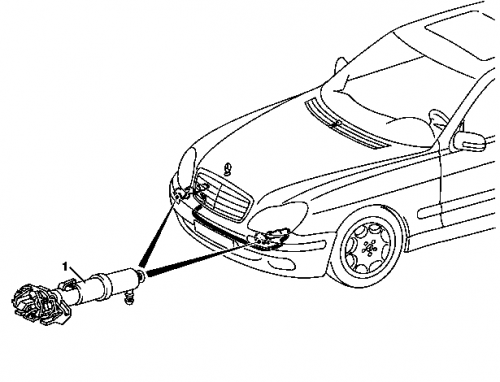

=== Telescoping nozzles === | |||

<!-- GF82.15-P-2100-01S Telescoping nozzle headlamp cleaning system, location --> | |||

{| | |||

|[[File:W220_headlamp_cleaning_system_nozzles.png|500px]] | |||

|* 1 - Telescoping nozzles | |||

|} | |||

<!-- GF82.15-P-2100S | |||

Telescoping nozzle headlamp cleaning system (HCS), location/purpose/design/ function | |||

MODEL 215, 220 with CODE (600a) Headlamp cleaning system --> | |||

The telescoping nozzles are hydraulically extending telescopic tubes with integrated return spring. | |||

They are not connected electrically. | |||

<!-- GF82.15-P-2100-04B | |||

Telescoping nozzle headlamp cleaning system, function --> | |||

When it starts running the washing water pump builds up pressure in the washing water line. | |||

The nozzles extend in a telescopic manner at a pressure of 1-1.6 bar. | |||

When a pressure of 3 bar is exceeded a valve opens on each telescoping nozzle | |||

and a precise quantity of washing water is sprayed onto the headlamp lenses. | |||

Eddy chambers are attached to the tips of the telescopic nozzles | |||

which control the spray from the water jets even at high vehicle speeds. | |||

Following the cleaning process the telescopes are retracted to the initial position by return springs. | |||

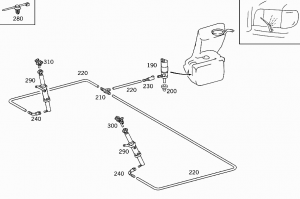

=== Parts === | |||

[[File:W220_headlamp_washer_EPC.png|thumb|none|Parts in [[EPC]] related to headlamp washing system]] | [[File:W220_headlamp_washer_EPC.png|thumb|none|Parts in [[EPC]] related to headlamp washing system]] | ||

Revision as of 19:05, 11 February 2023

Headlamp cleaning system (HCS)

The purpose of headlamp cleaning system (HCS) is cleaning headlamp lenses.

Location of components:

Function precondition:

- Circuit 15 ON

Manual operation

- The headlamp cleaning system (HCS) is switched on by pressing the HCS switch (S1s1).

- This connects the corresponding input of the left front SAM control unit (N10/6), which reads in the signal of the HCS switch (S1s1), to ground.

- The left front SAM control unit (N10/6) places the switch-on pulse onto the class B Controller Area Network bus (interior) (CAN-B) as a message.

- The right front SAM control unit (N10/7) reads in this message and connects circuit 15 to the HCS pump (M5/2) for a switch-on time of approx. 1 s via an electronic switch (transistor).

- The HCS pump (M5/2) builds up water pressure in the line.

- The water pressure acts against the return springs in the telescopic nozzle.

- Before the telescopic nozzles extend, spraying water on the headlamp lenses.

- After expiration of the switch-on time, the pressure in the water line decreases and the telescopic nozzles are retracted to their initial position by the spring force.

Pressing the HCS switch (S1s1) again when a headlamp cleaning cycle is being performed has no effect. Another headlamp cleaning cycle cannot be activated until the preceding one has completed.

Automatic operation (in vehicles as of 1.6.04)

After the windshield washer system has been operated 15 times the HCS pump (M5/2) is actuated automatically. This automatic control is performed by the right front SAM control unit (N10/7).

Function: For each actuation of the windshield washer fluid pump (M5/1) the internal counter in the right front SAM control unit (N10/7) is incremented by 1 until it reaches the value "15", then the HCS pump (M5/2) is actuated and the counter is reset to "0". The internal counter is always reset to "0" whith circuit 15 off.

Telescoping nozzles

|

* 1 - Telescoping nozzles |

The telescoping nozzles are hydraulically extending telescopic tubes with integrated return spring.

They are not connected electrically.

When it starts running the washing water pump builds up pressure in the washing water line. The nozzles extend in a telescopic manner at a pressure of 1-1.6 bar. When a pressure of 3 bar is exceeded a valve opens on each telescoping nozzle and a precise quantity of washing water is sprayed onto the headlamp lenses.

Eddy chambers are attached to the tips of the telescopic nozzles which control the spray from the water jets even at high vehicle speeds. Following the cleaning process the telescopes are retracted to the initial position by return springs.

Parts

Check also the windshield washing system.

Headlight Washer Removal