WIS 82.25 Signalling Equipment/Emergency Alarm System

Issues - Turn Signal Indicators

Applying a turn signal produces an error code such as "check the right turn indicator globe" and fast (double frequency) flashing of the dashboard light. The external turn indicators still flash at the correct frequency.

The issue may only happen occasionally and resets when the ignition is turned off, although the ECU stores a fault.

It can be very frustrating especially when you check all the turn indicator globes and they appear all OK.

There are several possible causes for the error code such as "check the right turn indicator globe".

Issue 1 - Problem with External Mirror Turn Signal Indicators

A common issue with the External Mirror Turn Signal LEDs is a broken wire where the wires flex when the mirror folds.

One or all of the LEDs work intermittently caused by bad connections on the LED printed circuit boards.

The LEDs in an external mirror may be glowing dimly.

The problem can be, but is most likely NOT, the passenger side door control module (DCM) which controls the seat heater, seat controls, window and mirrors.

Solution 1A - Broken Wires in External Mirror Turn Signal LEDs

- Remove the mirror by pressing in a small spring clip at the top.

- Release the mirror housing cover by also pressing in a spring clip near the outer edge.

- Unclip the LED unit from the housing.

- Plug the LED unit into the connector.

- Turn the emergency flashers on (no need for the ignition switch to be on).

- Test by carefully pulling and pushing the thin, identical black wires where they bend when the mirror folds until you find a faulty wire.

- Usually they break inside the insulation, which is not visible.

- It may also be inside the mirror structure where a splice is not possible.

- Remove the insulation at the break.

- Splice in an additional two-inch piece of wire which should allow you to pull the broken ends out of the structure

- Complete the repair by splicing together each broken end.

- Take the time to very carefully seal the seams on the LED unit with clear RTV silicone, which helps prevent water getting into the unit.

- Reinstall

Problem solved - less than an hour and no cost.

- With thanks to wallyp at reference: http://www.benzworld.org/forums/w220-s-class/1707657-s500-w220-mirror-turn-signal-issues.html

Solution 1B - Faulty LEDs or LED Joints in External Mirror Turn Signal LEDss

- Remove the mirror by pressing in a small spring clip at the top.

- Release the mirror housing cover by also pressing in a spring clip near the outer edge.

- Unclip the LED unit from the housing.

- Test the individual LEDs on the bench with a suitable power supply.

- The OEM LED joints are crimped.

- Resolder all the LED joints.

- If any LEDs are faulty they can be replaced individually.

- Factory LEDs are 4.5W.

- Typical replacements are 5W but don’t have enough resistance.

- Solder three 33 Ohm, 1/2 W resistors from Radio Shack, in to the wiring.

- Clean and lubricate all the connectors with rubber grease (helps prevent water ingress).

- Put rubber grease on the seals.

- Reinstall

Issue 2 - Problem with Rear Turn Signal Indicators

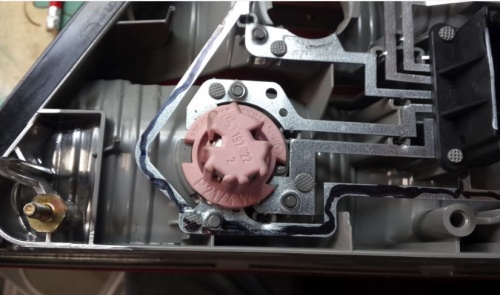

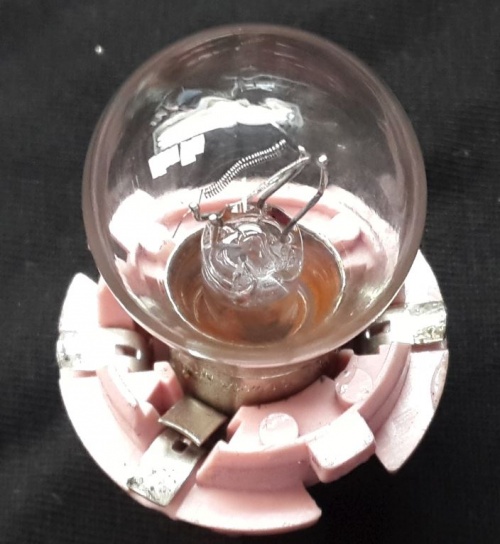

A common issue with the Rear Turn Signal Indicators is oxidized contacts on the bulb socket. The next photograph shows the Rear Left Tail Light and Fog Light Bulb Holder in its socket.

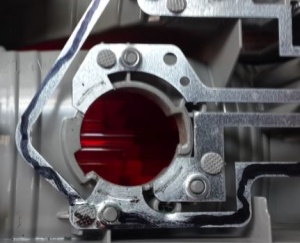

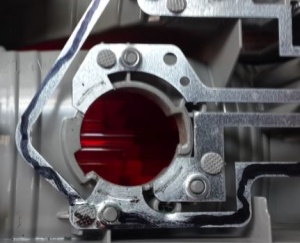

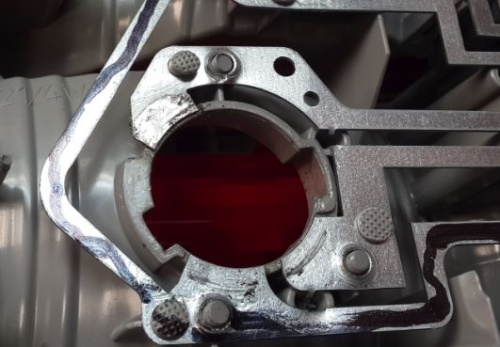

The next photograph shows the oxidized contact marks on the socket when the Rear Left Tail Light and Fog Light Bulb Holder is removed.

Obviously if the Turn Signal Indicators are showing signs of oxidation then so are all the other bulb holders and their sockets.

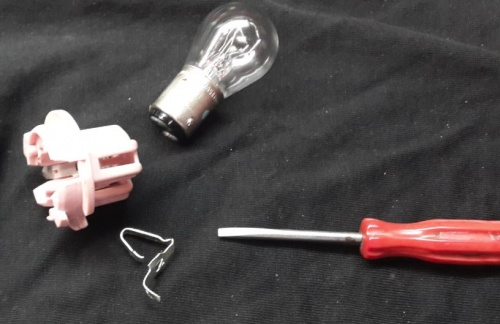

Solution 2 - Problem with oxidized contacts on the Rear Bulb Holders

- Remove the boot lining as required.

- Remove the Rear Light Assembly. [10mm socket]

- Note the position of the coloured bulb holders.

- Black - Reverse Light

- White - Turn Indicator

- Pink - Fog and Tail Lights

- Remove just one bulb holder from its socket (Even though the bulb holders are all uniquely coded it is easier to modify them one at a time.)

- Note the position of the contact marks on the bulb holder socket. (The contact marked with a black felt tip pen is the earth or zero volts contact.)

- Clean the contact points on the bulb holder socket with solvent.

- Lightly scuff the contact points on the bulb holder socket with sand paper.

- Using a soldering iron tin the contact points on the bulb holder socket.

- Repeat for the other contact points on this socket.

- Now move your attention to the mating Bulb Holder.

- Inspect this Bulb Holder Socket's Contact points and note the oxidation.

- Remove the globe.

- Remove just one contact by depressing the tab with a small screw driver.

- Clean the contact areas on the bulb holder contact with solvent.

- Lightly scuff the contact areas on the bulb holder contact with sand paper.

- Using a soldering iron tin the contact areas on the bulb holder contact.

- Reinsert the bulb holder contact into the bulb holder BEFORE doing the next one.

- Repeat for all other contacts.

- Reinstall the Bulb Holder in its socket, BEFORE moving on to the next one.

- Repeat for all other bulb holders and sockets.

- Check the resistances of each light and its circuit by using a DVM to measure the resistances from the cable connection. (Clip one side of the DVM to the earth lead marked with a black felt tip pen in the photo above.)

- Reverse Light (Black Bulb Holder) 0.6 Ohms.

- Turn Indicator (White Bulb Holder) 0.6 Ohms.

- Tail Light (One filament in Pink Bulb Holder) 0.6 Ohms.

- Fog Light (one filament in Pink Bulb Holder) 5 Ohms.

- Reinstall the rear tail light assembly and repeat for the other side.