Front seats: Difference between revisions

| Line 356: | Line 356: | ||

* 1 - Two air cushions for the shoulder region | * 1 - Two air cushions for the shoulder region | ||

* 2 - Two air cushions for the side region | * 2 - Two air cushions for the side region | ||

* 3 - Three air cushions for the | * 3 - Three air cushions for the lumbar support region | ||

* 4 - Operating switches | * 4 - Operating switches | ||

|} | |} | ||

The multicontour backrest of the multicontour seat enables individual | The multicontour backrest of the multicontour seat enables individual | ||

adjustment of the seat backrest by filling and venting a total of seven | adjustment of the seat backrest by filling and venting a total of seven | ||

| Line 376: | Line 375: | ||

pressure values) is possible with the memory feature. | pressure values) is possible with the memory feature. | ||

As of 01/06/2001 the switch group has a different design. | As of 01/06/2001 the switch group has a different design. | ||

The modifications are shown in the | The modifications are shown in the multicontour switch section below. | ||

===Multicontour seat control module=== | |||

<!-- GF91.25-P-2101S, Multicontour seat control module, location/task/design/function, 27.4.98 | |||

MODELS 215, 220 up to 31.8.02 with CODE (404b) Multicontour backrest driver seat | |||

MODELS 215, 220 up to 31.8.02 with CODE (405b) Multicontour backrest passenger seat | |||

MODEL 220 up to 31.8.02 with CODE (224c) Electrically adjustable rear single seats, with seat ventilation, seat heater and memory package | |||

--> | |||

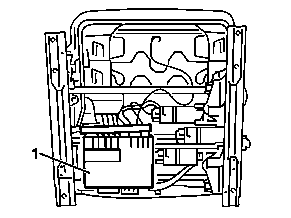

The left front multicontour backrest control module (N32/15)/the right front multicontour | |||

backrest control module (N32/16) is located under the respective seat. | |||

The rear multicontour backrest control module (N32/14) is located under the right half of the rear seat bench. | |||

Apart from the actuation/evaluation | |||

electronics, pressure control valves (one for | |||

each air cushion) are located in all control | |||

modules of the multicontour backrests. The | |||

air cushions are filled and emptied via these | |||

pressure control valves. | |||

The control module reads in the switch | |||

conditions of the switch groups of the | |||

multicontour backrests, detects the air | |||

pressure in the air cushions via piezoresistive | |||

pressure sensors, actuates the pressure | |||

control valves and receives/sends data from/ | |||

to the respective seat control module. | |||

{| | |||

|[[File:W220_left_front_multicontour_backrest_control_module.jpg]] | |||

| | |||

* | * N32/15 - Left front multicontour backrest control module | ||

* | * N32/16 - Right front multicontour backrest control module | ||

|} | |||

{| | |||

|[[File:W220_rear_multicontour_backrest_control_module.jpg]] | |||

| | |||

* N32/14 - Rear multicontour backrests control module | |||

|} | |||

''' | <!-- GF91.25-P-2101-02S, Multi-contour seat control modules, purpose --> | ||

The multi-contour backrest control module is responsible for: | |||

* Inflating and deflating the multi-contour backrest according to the control actions read in from the multi-contour backrest switches | |||

* Control of dynamic lumbar feature, actuated with multi-contour backrest switch ''"PULSE" button'' | |||

* Sensing of actual pressure values in air cushions with piezoresistive pressure sensors | |||

* Generating status data logs on the cushion inflation and transferring these logs to the associated seat control module via a bidirectional, serial interface. | |||

In context with the memory feature: | |||

* | * Communication with the corresponding control module via interface, particularly regarding storage and recall of stored seat positions | ||

* | * Setting stored seat positions (pressure values) and other settings when the memory feature is called | ||

===Multicontour seat switches=== | |||

<!-- GF91.25-P-2100S, Multi-contour seat switches, location/purpose/design/function, 27.4.98 | |||

MODEL 215, 220 with CODE (404b) Driver's seat with multi-contour backrest | |||

MODEL 215, 220 with CODE (405b) Passenger seat with multi-contour backrest | |||

MODEL 220 with CODE (224c) Rear bucket seats, electrically adjustable, with seat ventilation, seat heater and memory package | |||

--> | |||

<!-- GF91.25-P-2100-01S, Multi-contour seat switch position--> | |||

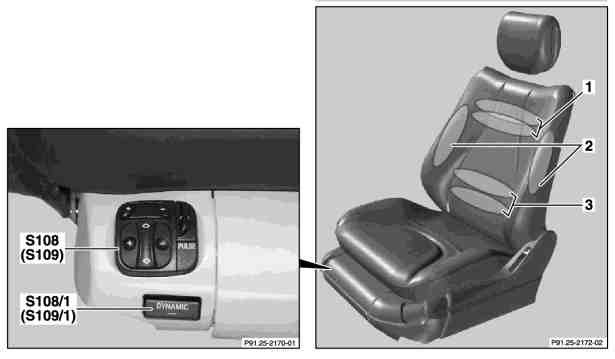

The switch train for the front right (S108)/front left (S109)/rear right (S103)/rear left | |||

(S104) multi-contour backrest is located in the corresponding seat, on the outer side of the | |||

seat cushion frame. | |||

{| | |||

|[[File:W220_multicontour_seat_switch_up_to_31-05-2001.jpg|thumb|none|Front left seat up to 31/05/2001.]] | |||

| | |||

* 1 - Switch train for front left multi-contour backrest (S109) | |||

|} | |||

The switch can be used for manually inflating and deflating lumbar | |||

cushion group, side backrest cushions and also, on front seats only, shoulder cushion | |||

group. An additional switch serves for activating and deactivating the dynamic | |||

lumbar adjustment feature. | |||

The switch positions are voltage-coded by means of resistors. | |||

The coded voltages are then read in by the corresponding multi-contour backrest control module. | |||

''' | <!-- GF91.25-P-2100-02S, Multi-contour seat switch structure --> | ||

'''Front seat switch''' | |||

The | The switch train in the left/right front seat is equipped with a rocker switch for controlling | ||

shoulder cushion and lumbar cushion pulsation. A further rocker switch is used | |||

right front | to control the inflation and deflation of the two seat backrest cushions for lateral support. | ||

A ''"PULSE"'' button is additionally available for switching the dynamic lumbar support on and off. | |||

{| | |||

|[[File:W220_front_seat_switch_train_up_to_31-05-2001.jpg|thumb|none|Front seat switch train up to 31/05/2001.]] | |||

* Switch | |[[File:W220_front_seat_switch_train_as_of_01-06-2001.jpg|thumb|none|Front seat switch train as of 01/06/2001.]] | ||

* Switch | | | ||

* | * S108 - Switch train for front right multi-contour backrest | ||

* S109 - Switch train for front left multi-contour backrest | |||

* S108s1/S109s1 - Switch for dynamic lumbar support adjustment | |||

* S108s2/S109s2 - Switch for seat cushion side adjustment | |||

* S108s3/S109s3 - Switch for lumbar support adjustment | |||

* S108s4/S109s4 - Switch for shoulder area adjustment | |||

|} | |||

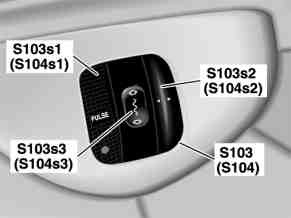

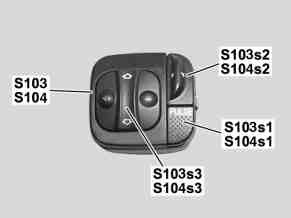

''' | '''Rear seat switch''' | ||

The switch train in the left/right rear individual seat is equipped with a rocker switch for | |||

controlling lumbar support cushion pulsation. A further rocker switch is used to control the | |||

inflation and deflation of the two seat backrest cushions for lateral support. A ''"PULSE"'' button is | |||

additionally available for switching the dynamic lumbar support on and off. | |||

{| | |||

|[[File:W220_individual_rear_seat_switch_train_up_to_31-05-2001.jpg|thumb|none|Individual rear seat switch train up to 31/05/2001.]] | |||

|[[File:W220_individual_rear_seat_switch_train_as_of_01-06-2001.jpg|thumb|none|Individual rear seat switch train as of 01/06/2001.]] | |||

| | |||

* S103 - Switch for rear right multi-contour backrest | |||

* S104 - Switch for rear left multi-contour backrest | |||

* S103s1/S104s1 - Switch for dynamic lumbar support adjustment | |||

* left | * S103s2/S104s2 - Switch for seat cushion side adjustment | ||

* | * S103s3/S104s3 - Switch for lumbar support adjustment | ||

|} | |||

* | |||

===Adjust front multicontour seats function=== | ===Adjust front multicontour seats function=== | ||

| Line 569: | Line 551: | ||

air cushions as per the stored values. | air cushions as per the stored values. | ||

As of 01/09/2002 codes 344 and 343 | |||

As of 01/09/2002 the left front dynamic seat control module (N32/19) | the left front dynamic seat control module (N32/19) | ||

and right front dynamic seat control module (N32/22) are | and right front dynamic seat control module (N32/22) are | ||

responsible for the memory feature. | responsible for the memory feature. | ||

===Manual | |||

===Manual adjustment of air cushions in the multicontour seat=== | |||

<!-- GF91.25-P-2000S, Manual filling/emptying of air in the air cushions in the multicontour seat, function, 29.4.98 | <!-- GF91.25-P-2000S, Manual filling/emptying of air in the air cushions in the multicontour seat, function, 29.4.98 | ||

MODEL 220 with CODE (404b) Multicontour backrest driver seat | MODEL 220 with CODE (404b) Multicontour backrest driver seat | ||

| Line 587: | Line 570: | ||

* Circuit 15 ON | * Circuit 15 ON | ||

The air cushions of the multicontour backrest can be adjusted | The air cushions of the multicontour backrest can be adjusted | ||

manually via the right rear/left rear multicontour backrest switch | manually via the right rear/left rear multicontour backrest switch | ||

| Line 604: | Line 586: | ||

module. | module. | ||

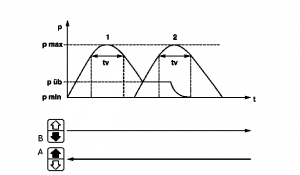

'''Manual adjustment of the shoulder region''' | |||

and | Manual adjustment of the shoulder region by switch for the | ||

shoulder region (S103s4/S104s4). | |||

For driver's and front passenger's seat only. | |||

This provision for adjustment is not realized for the individual rear seats. | |||

{| | {| | ||

|[[File:W220_manual_adjustment_of_the_shoulder_region.png]] | |[[File:W220_manual_adjustment_of_the_shoulder_region.png|thumb|none|Manual adjustment of the shoulder region.]] | ||

| | | | ||

* A - Top half of the switch | * A - Top half of the switch | ||

* B - Bottom half of the switch | * B - Bottom half of the switch | ||

|} | |} | ||

Pressing the bottom half of the switch: | |||

Air cushions 1 and 2 of the shoulder region are filled in sequence | Air cushions 1 and 2 of the shoulder region are filled in sequence | ||

from top to bottom up to the maximum pressure and then emptied | from top to bottom up to the maximum pressure and then emptied | ||

| Line 629: | Line 607: | ||

air cushion 2 is at minimum pressure. | air cushion 2 is at minimum pressure. | ||

Pressing the top half of the switch: | |||

The air cushions are filled in the reverse order, thus from the bottom | The air cushions are filled in the reverse order, thus from the bottom | ||

upwards and then emptied (see above). | upwards and then emptied (see above). | ||

| Line 644: | Line 613: | ||

The transfer pressure p üb and the dwell period tv are adjustable. | The transfer pressure p üb and the dwell period tv are adjustable. | ||

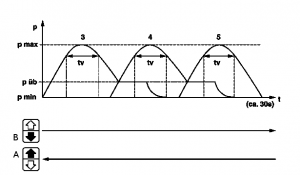

'''Manual adjustment of the lumbar support region''' | |||

Manual adjustment of the lumbar support region by the lumbar | |||

support adjustment switch (S103s3/S104s3) right front/left front | |||

lumbar support adjustment switch (S108s3/S109s3). | |||

{| | {| | ||

|[[File:W220_manual_adjustment_of_the_lumbar_support_region_of_the_front_rear_seat.png]] | |[[File:W220_manual_adjustment_of_the_lumbar_support_region_of_the_front_rear_seat.png|thumb|none|Manual adjustment of the lumbar support region.]] | ||

| | | | ||

* A - Top half of the switch | * A - Top half of the switch | ||

| Line 659: | Line 626: | ||

|} | |} | ||

Pressing the bottom half of the switch: | |||

Air cushions 3, 4, 5 of the lumbar support region are filled from top to | |||

Pressing the bottom half of the switch | |||

bottom up to the maximum pressure and then emptied again down to | bottom up to the maximum pressure and then emptied again down to | ||

the minimum pressure. The process stops as soon as air cushion 5 | the minimum pressure. The process stops as soon as air cushion 5 | ||

has reached the minimum pressure. | has reached the minimum pressure. | ||

Pressing the top half of the switch: | |||

The air cushions are filled in the sequence 5, 4, 3, so from top to | The air cushions are filled in the sequence 5, 4, 3, so from top to | ||

bottom and then emptied again (see above). | bottom and then emptied again (see above). | ||

The transfer pressure p üb and the dwell period tv are adjustable. | The transfer pressure p üb and the dwell period tv are adjustable. | ||

===Dynamic lumbar support of multicontour backrest=== | |||

===Dynamic | |||

<!-- GF91.25-P-2001S, Dynamic filling/emptying of air in the air cushions in the multicontour seat, function, 29.4.98 | <!-- GF91.25-P-2001S, Dynamic filling/emptying of air in the air cushions in the multicontour seat, function, 29.4.98 | ||

MODEL 220 with CODE (404b) Multicontour backrest driver seat | MODEL 220 with CODE (404b) Multicontour backrest driver seat | ||

| Line 708: | Line 647: | ||

with CODE (434) Right dynamic seat, incl. multicontour seat | with CODE (434) Right dynamic seat, incl. multicontour seat | ||

--> | --> | ||

In order to prevent stresses in the back on longer journeys, the | |||

multicontour backrest is equipped with the dynamic lumbar support | |||

function. The function is controlled in the relevant seat by the | |||

multicontour backrest control module. It is triggered by pressing ''"PULSE" button'' on | |||

the dynamic lumbar support adjustment switch (S103s1/S104s1/S108s1/S109s1) | |||

in the left rear/right rear multicontour backrest | |||

switch group (S103, S104) and right front/left front multicontour | |||

backrest switch group (S108, S109). | |||

Lumbar support: curvature of spine in lumbar region. | |||

Starting with the air cushion which is currently active the pulsation | |||

occurs alternately in the two lumbar support cushions in the | |||

sequence lower and upper lumbar (sequence is parameterizable). | |||

Filling starts with the active lumbar support cushion up to the next | |||

pressure level, unless the upper pressure level has already been | |||

reached or exceeded. Each air pressure adjustment is held for | |||

approx. 10 seconds before the next condition is assumed. After | |||

approx. 8 minutes the program is terminated automatically and the | |||

original air cushion pressures are reproduced. | |||

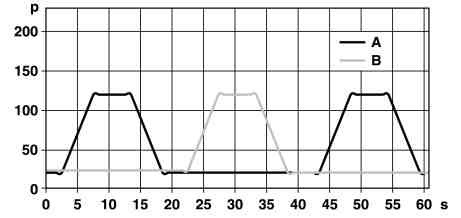

Illustration shows function sequence for dynamic lumbar support: | Illustration shows function sequence for dynamic lumbar support: | ||

[[File:W220_function_sequence_for_dynamic_lumbar_support.png|400px]] | [[File:W220_function_sequence_for_dynamic_lumbar_support.png|400px]] | ||

First of all the three lumbar support air cushions of the multicontour | First of all the three lumbar support air cushions of the multicontour | ||

| Line 722: | Line 679: | ||

The function can be terminated at any time by pressing the switch again. | The function can be terminated at any time by pressing the switch again. | ||

== Dynamic seat function == | |||

<!-- GF91.25-P-0001S --> | |||

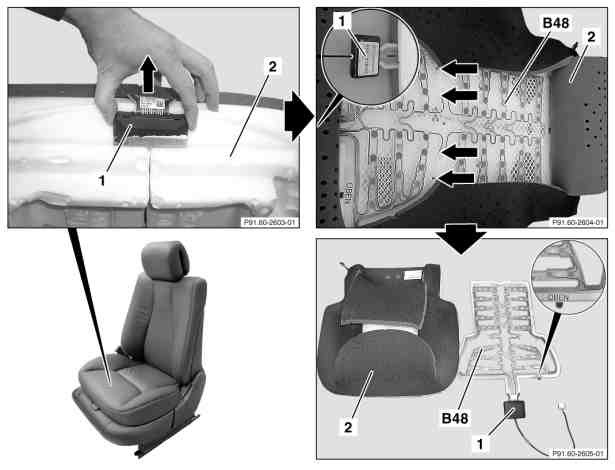

'''Dynamic seat (FDS) as of 01/09/2002 function with codes 433 and 434''' | |||

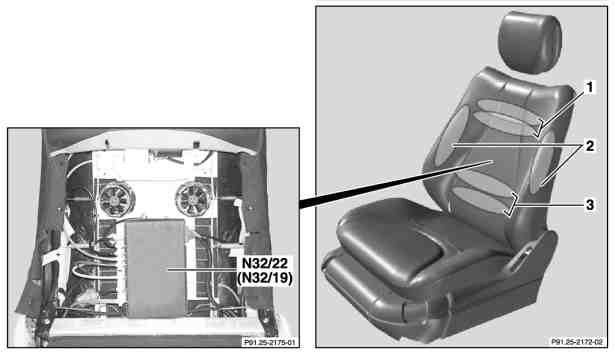

Illustration shows Dynamic seat (FDS) as of 01/09/2002 with codes 433 and 434: | |||

{| | {| | ||

|[[File: | |[[File:W220_dynamic_seat_facelift.jpg]] | ||

| | | | ||

* | * 1 - Air cushion for the shoulder region (coupled) | ||

* | * 2 - Air cushion for the respective side region | ||

* 3 - Air cushion for the upper and lower lumbar support region | |||

|} | |} | ||

| Line 748: | Line 695: | ||

driver's seat and also apply to the front passenger's seat. | driver's seat and also apply to the front passenger's seat. | ||

'''Dynamic lumbar support''' | The dynamic seat comprises the functions: | ||

* Memory multicontour backrest (MMKL) | |||

* Dynamic side support | |||

'''Memory multicontour backrest (MMKL)''' | |||

The multicontour backrests enable individual adjustment of the | |||

respective seat backrest by filling and emptying up to three air | |||

cushion groups: | |||

* Air cushion for the upper and lower shoulder region | |||

* Air cushion for the respective side region | |||

* Air cushion for the upper and lower lumbar support region | |||

The "Dynamic lateral support" function is switched on or off by | |||

pressing the FDS ''"DYNAMIC"'' button and is controlled by the left front dynamic | |||

seat control module (N32/19). If the function is activated, this is | |||

displayed by an LED in the FDS ''"DYNAMIC"'' button. The left front dynamic seat | |||

control module (N32/19) adjusts after that a corresponding basic | |||

pressure in the lateral support cushions and, when cornering, | |||

ensures better retention in the lateral support by temporarily adding | |||

pressure to the lateral support cushions on the outside of the curve. | |||

This essentially happens as a function of the instantaneous speed | |||

and the lateral acceleration. This information comes from the traction | |||

systems control module (N47) and is transmitted by central gateway | |||

control module (N93) from CAN-C (engine compartment) to CAN-B | |||

(interior). If the data for the FDS function fail for more than 2 | |||

seconds, the function is switched off and remains switched off. | |||

The extent and speed with which the lateral support cushions for the | |||

driver's and front passenger's seat are filled can be adjusted via the | |||

second operating level of the instrument cluster (A1). | |||

'''Priority sequence of the functions''' | |||

The priorities are set in the sequence: | |||

* Priority 1 Lumbar support | |||

* Priority 2 Shoulder region (not for individual rear seats) | |||

* Priority 3 Lateral support | |||

* Priority 4 Dynamic lumbar support and dynamic lateral support (front seats only) | |||

When pressing multiple rocker switches at the same time, only the | |||

adjustment movement with the highest priority is executed. | |||

'''Abort criteria''' | |||

All functions are interrupted if there is overvoltage or undervoltage. | |||

The relevant function is not performed if a valve has overheated or | |||

there is a leakage fault. | |||

'''Limit stop emptying''' | |||

If the end point is reached after the lumbar support wave has | |||

passed, the inactive air cushion is emptied for as long as the switch | |||

is pressed, but for a maximum period of 1 minute. | |||

'''Control functions''' | |||

The adjusted specified pressures of the individual cushion areas are | |||

controlled by the left front dynamic seat control module (N32/19) and | |||

right front dynamic seat control module (N32/22) in each case in a | |||

manner which is unnoticeable for the customer provided that the | |||

function conditions for manual adjustment are met. | |||

The contour and surface hardness of the seat backrest can be | |||

adjusted manually via the: | |||

* Switch group for right front multicontour backrest (S108) | |||

* Switch group for left front multicontour backrest (S109) | |||

* the "dynamic lumbar support" function. | |||

'''Dynamic lateral support (driver's/front passenger's seat)''' | |||

Function requirements: | |||

* Circuit 15R ON | |||

* Circuit 15 ON | |||

* No undervoltage or overvoltage | |||

* No overtemperature sensor | |||

* No leakage fault in the lateral support region | |||

Sport (stage 1): Extra pressure is applied more quickly and more intensely to the | |||

lateral support cushions on the outside of the curve. | |||

Comfort (stage 2): Extra pressure is applied slowly and less intensely to the lateral | |||

support cushions on the outside of the curve. | |||

Definitively the following control modules are involved in the dynamic seat: | |||

* left front dynamic seat control module (N32/19) | |||

* right front dynamic seat control module (N32/22) | |||

* central gateway control module (N93) | |||

* traction systems control module (N47) | |||

'''Background functions''' | |||

In the lumbar support region the cushions are arranged overlapping | |||

and consequently coupled in their function during the wave | |||

sequence. As only one air cushion is active in each case, the | |||

adjacent cushions are considered as not active i.e. empty. The | |||

following background functions are necessary to ensure this. | |||

'''Idle time emptying (optional)''' | |||

While the pressure is kept constant in the active air cushion | |||

(residence time), the adjacent non-active air cushions are emptied. | |||

'''Backgrounds emptying''' | |||

If the active air cushion is emptied, then the residual pressure in the | |||

adjacent non-active air cushions is also reduced, as soon as the air | |||

cushions have the same pressure. | |||

the | |||

The subsequent regulation follows, for example, in the event of | |||

pressure deviations caused by: | |||

* The respective person sitting in or leaning on the seat | |||

* Leakage in the seat inflators | |||

* Temperature changes caused by heated seats, insolation, air conditioning and user warmth | |||

Sudden changes in pressure which arise due to the person sitting in | |||

on leaning on the seat are adjusted immediately and in a comfort- | |||

orientated manner. The control parameters that are listed can be | |||

programmed using diagnosis. | |||

===Dynamic seat control module=== | ===Dynamic seat control module=== | ||

| Line 810: | Line 856: | ||

under the front multicontour backrest switch group on the seat cushion. | under the front multicontour backrest switch group on the seat cushion. | ||

The switch turns the dynamic lateral support function on and off. | |||

{| | {| | ||

| Line 824: | Line 870: | ||

|} | |} | ||

=== | ===Manual adjustment of air cushions in the dynamic multicontour seat=== | ||

All the following provisions for adjustment are explained on the | |||

driver's seat and also apply to the front passenger's seat. | |||

'''Manual adjustment of the shoulder region as of 01/09/2002 with codes 433 and 434''' | |||

Air cushions 1 and 2 of the shoulder region are coupled and are | |||

adjusted with the shoulder region adjustment switch (S109s4). | |||

When the rocker switch is pressed towards "+" or "-" the backrest | |||

contour in the shoulder region is changed by filling/emptying the air | |||

cushions. | |||

This provision for adjustment is not realized for the individual rear seats. | |||

'''Manual Adjustment of the lumbar support region as of 01/09/2002 with codes 433 and 434''' | |||

''' | |||

The | The lumbar support region of the seat is operated by the lumbar | ||

support adjustment switch (S109s3). | |||

When the cross rocker is pressed towards "+" or "-" the backrest contour changes in the | |||

lumbar support region by filling/emptying the air cushion which is | |||

currently active. | |||

When the cross rocker of the bottom half of the switch is pressed the | |||

backrest contour in the lumbar support region is changed sequentially. | |||

First, the lower air cushion is filled/emptied again and | |||

then the upper air cushion is filled. Only one air cushion is actuated | |||

actively in this process. This sequence starts with the air cushion | |||

which has just become active. | |||

When the cross rocker of the top half of the switch is pressed the | |||

sequence is the same as when the bottom half of the switch is | |||

pressed, only in the reverse order. | |||

The upper air cushion is emptied first and then the lower air cushion | |||

is filled. | |||

===Dynamic lumbar support=== | |||

<!-- GF91.25-P-2001S--> | |||

All the following provisions for adjustment are explained on the | |||

driver's seat and also apply to the front passenger's seat. | |||

''' | In order to prevent stresses in the back on longer journeys, the | ||

dynamic seat multicontour backrest is equipped with the dynamic lumbar support | |||

function. The function is controlled in the relevant seat by the | |||

multicontour backrest control module. | |||

It is triggered by pressing ''"PULSE" button'' on | |||

the dynamic lumbar support adjustment switch (S103s1/S104s1/S108s1/S109s1) | |||

in the left rear/right rear multicontour backrest | |||

switch group (S103, S104) and right front/left front multicontour | |||

backrest switch group (S108, S109). | |||

Lumbar support: curvature of spine in lumbar region. | |||

Starting with the air cushion which is currently active the pulsation | |||

occurs alternately in the two lumbar support cushions in the | |||

sequence lower and upper lumbar (sequence is parameterizable). | |||

Filling starts with the active lumbar support cushion up to the next | |||

pressure level, unless the upper pressure level has already been | |||

reached or exceeded. Each air pressure adjustment is held for | |||

approx. 10 seconds before the next condition is assumed. After | |||

approx. 8 minutes the program is terminated automatically and the | |||

original air cushion pressures are reproduced. | |||

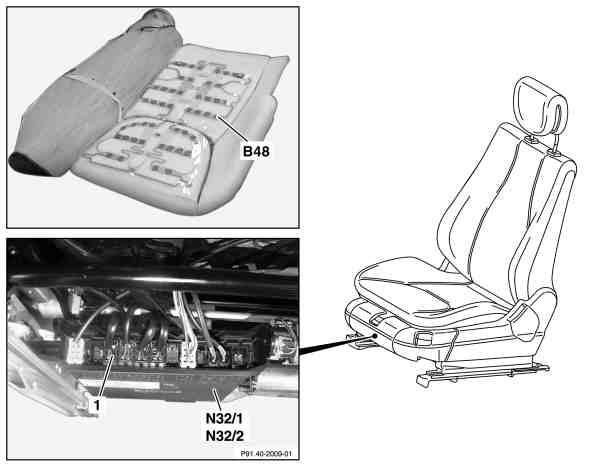

Illustration shows function sequence of dynamic lumbar support as of 01/09/2002 with codes 433 and 434: | |||

{| | {| | ||

|[[File: | |[[File:W220_function_sequence_of_dynamic_lumbar_support_code_443_434.jpg]] | ||

| | | | ||

* | * A - Upper lumbar support | ||

* | * B - Lower lumbar support | ||

|} | |} | ||

The function is controlled by the left front dynamic seat control | |||

module (N32/19). The program is started and stopped by the | |||

dynamic lumbar support adjustment switch (S109s1) ''"PULSE" button''. The active | |||

function is displayed by illuminating the LED in the switch. | |||

After the switch is pressed, first the air pressures of the air cushion in | |||

the lumbar support region are stored by the left front dynamic seat | |||

control module (N32/19). | |||

'' | |||

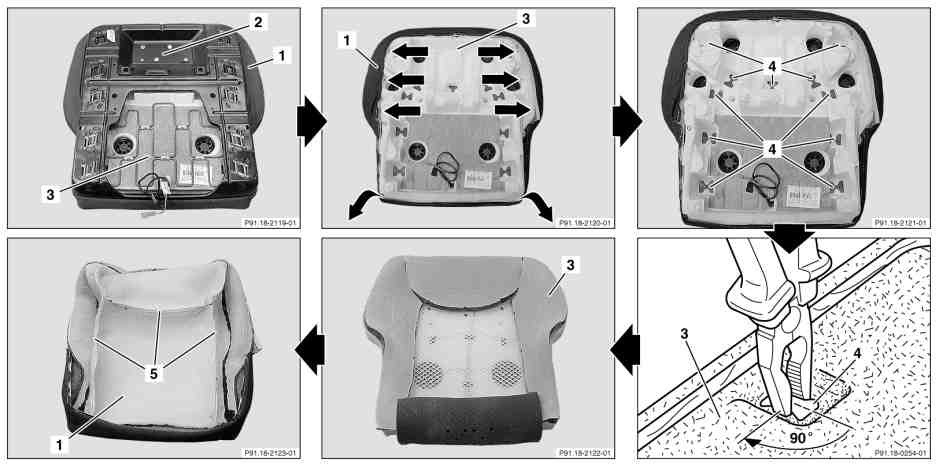

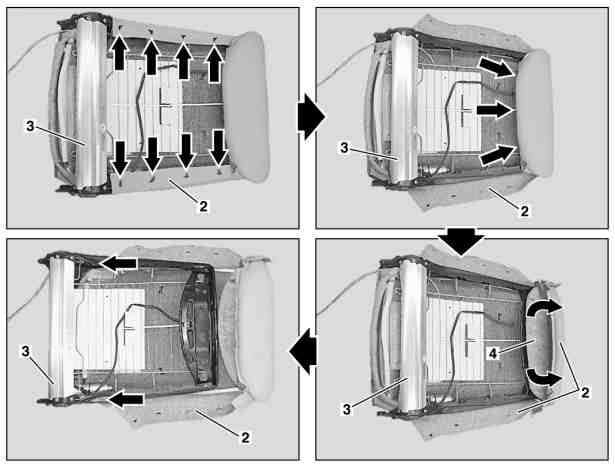

==Remove/install front seat backrest seat-back lining== | ==Remove/install front seat backrest seat-back lining== | ||

Revision as of 15:47, 30 August 2017

Front seat adjustment

The seat adjustment switches are located on the front doors.

- (1) Head restraint height

- (2) Seat height

- (3) Seat cushion tilt

- (4) Seat cushion depth

- (5) Seat fore and aft adjustment

- (6) Seat backrest tilt

To adjust the seat switch on ignition or open the respective door.

Seat fore and aft adjustment: Press the switch forward or backward in the direction of arrow (5). Adjust seat to a comfortable seating position that still allows you to reach the accelerator/brake pedal safely. The position should be as far to the rear as possible, consistent with ability to properly operate controls.

Seat cushion tilt: Press the switch up or down in the direction of arrow (3) until your upper legs are lightly supported.

Seat cushion depth: Press the switch forward or backward in the direction of arrow (4) until your legs are supported comfortably.

Seat backrest tilt: Press the switch forward or backward in the direction of arrow (6) until your arms are slightly angled when holding the steering wheel.

Seat height: Press the switch up or down in the direction of arrow (2).

Head restraint height: Press the switch up or down in the direction of arrow (1).

Head restraint tilt: Manually adjust the angle of the head restraint. Push or pull on the lower edge of the head restraint cushion.

Unoccupied front passenger seat automatic adjusting: The feature below is deactivated at the factory. If you wish to have it activated, use DAS. The front passenger seat head restraint automatically lowers after a few seconds when the front passenger seat is not occupied. This improves the driver's outward view as well as the forward view from the rear passenger compartment. When the front passenger seat is occupied again, the front passenger seat head restraint returns to the last set position within a few seconds. If the front passenger seat was moved fore or aft while not being occupied, the front passenger seat head restraint returns to a position that corresponds best with the seat’s axial position when the seat is occupied again.

Electric seat adjustment (ESA) function

Electric seat adjustment: The driver's and front passenger's seat are electrically adjustable. The adjustment takes place manually via the adjustment switches in the respective door control module. The ergo-function up to 31/05/2001 facilitates the adjustment. The individual seat positions can be stored and called up via the memory feature.

As of 01/06/2001 the ergonomics function is not used anymore for the front seat adjustment.

If the electrically adjustable rear bench seat is fitted (special equipment, model 220 only) the longitudinal position of the left and right halves of the seat bench can be adjusted manually using the adjusting switch in the respective door control module.

If electrically adjustable individual rear seats with memory are fitted (special equipment, model 220 only) likewise the longitudinal position and the backrest angle of the seat can be adjusted manually using the adjusting switches in the door control module. In addition it is possible to call up seat positions stored previously using the memory function

Electrically adjustable individual rear seats with memory: In addition it is possible to adjust the longitudinal position and the backrest angle of the front seat (front passenger's seat) via the door control module in the rear on the front passenger's side.

Entry/exit aid as of 01/09/2002 with code 275a: With the entry/exit aid the seat control module actuates the following control module when the key is removed:

- SAM/F (steering column)

- Overhead control panel (inside rearview mirror)

- Door control module (outside mirror)

The entry/exit aid enables the driver to get into and out of the vehicle more easily. Before the driver gets out the steering column is moved upwards and the seat is moved back. After getting in the position of the seat last adjusted is approached again or the last memory position is approached.

The driving position is stored key-dependent as is the memory position. Because of this if a key is changed a new driving position of seat, steering column and mirrors assigned to the key is adjusted. The entry/exit aid can be configured via the instrument cluster. The function can be switched off completely or partially (only the steering column is still active). On the V220 with individual rear seat system with code 275a the adjustment of a permanently defined position of the front passenger's and rear seat (park position) is possible from the rear door control module.

Adjusting front seats function

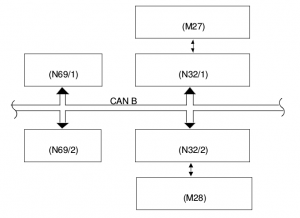

Block diagram for front seat adjustment:

Function requirements:

- No overvoltage or undervoltage

- Term.15R or 15 ON

- Respective vehicle door open

Adjusting front seats: The positions of the left and right front seat can be adjusted manually with the respective adjustment switches in the left front door control module (N69/1) and right front door control module (N69/2) in the driver's door and front passenger's door.

The following can be adjusted independently:

- The height of the head restraint

- The angle of the backrest

- The longitudinal position of the complete seat

- The position of the seat cushion

- The height of the rear half of the seat

- The height of the front half of the seat

Ergo function up to 31/05/2001:

The Ergo function up to 31/05/2001 facilitates manual adjustment. For this the seat adjustment must be correctly normalized.

Driver side: With the Ergo default setting, finding the right driver's seat position and the associated adjustments of the left and right outside mirrors, of the inside rearview mirror and steering column is facilitated. Once the default setting is complete only an individual fine adjustment is still necessary.

Passenger side: On the front passenger's side finding the correct front passenger's seat position is facilitated by the Ergo default setting.

As of 01/06/2001 the Ergo function is not used anymore, it is replaced by a further memory button.

Memory function up to 31/05/2001:

Using the memory feature, previously stored driver's and front passenger's seat positions can be approached automatically.

Driver side: On the driver's side two complete seat adjustments can be stored key-related and called up again. A total of eight memory areas are available. With the driver's seat adjustments the adjustments of the left and right outside mirrors, the inside rearview mirror and steering column are also stored.

Passenger side: On the front passenger's side two complete seat adjustments can be stored and called up again.

As of 01/06/2001 extended memory feature:

Driver side: On the driver's side three complete seat adjustments can now be stored and called up again for each transmitter key. Consequently a total of twelve memory areas are available. With the driver's seat adjustments the adjustments of the left and right outside mirrors, the inside rearview mirror and steering column are also stored.

Passenger side: On the front passenger's side three complete seat adjustments can be stored and called up again.

Seat adjusting motors position measurement function

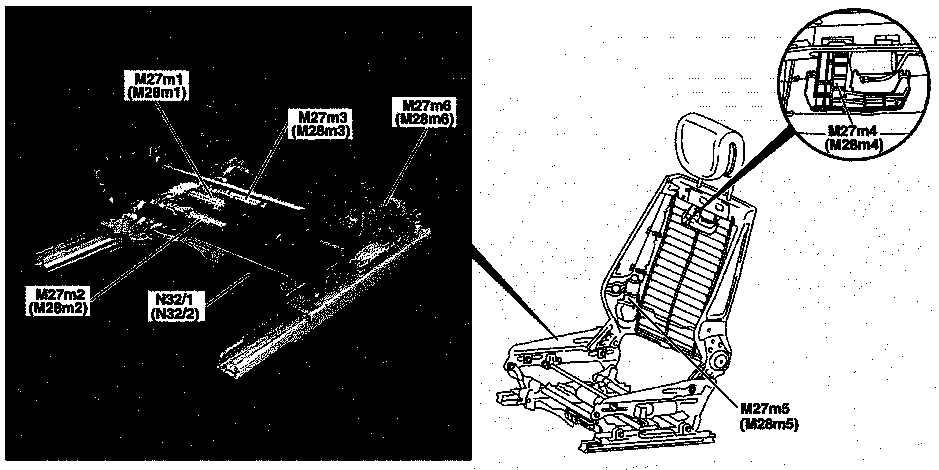

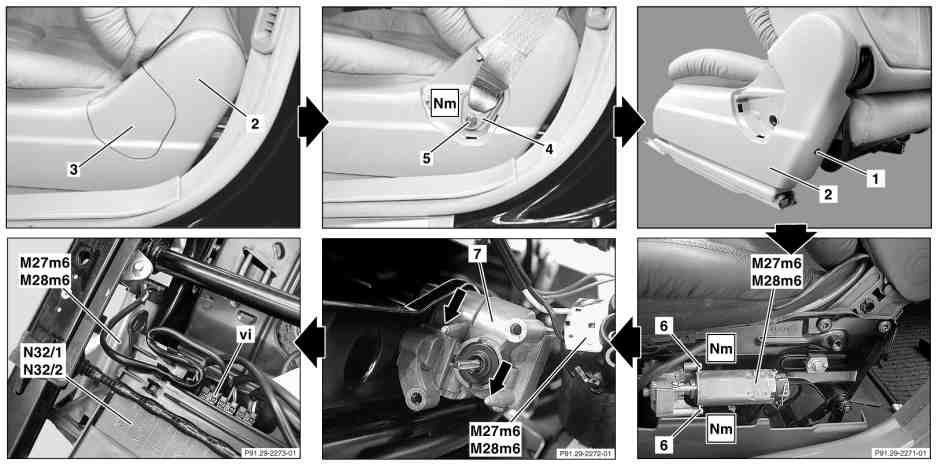

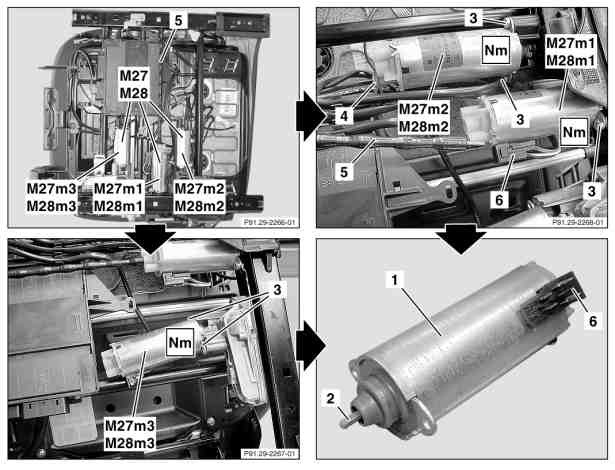

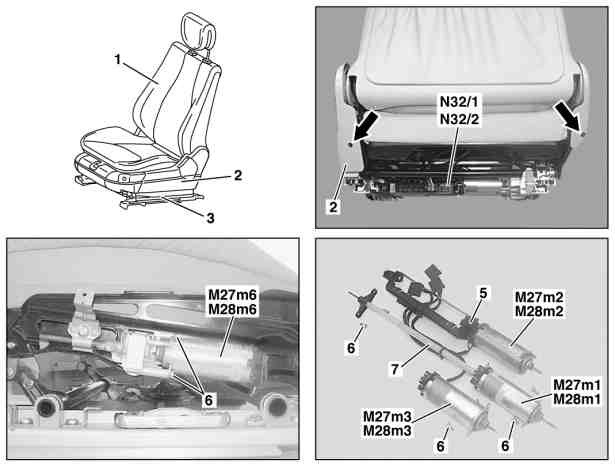

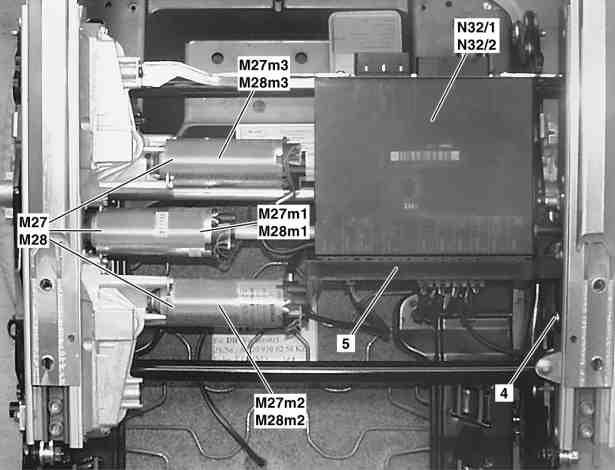

Left and right front seat: The adjustment motors of the front seats - left front seat adjustment motor group with memory (M27)/right front seat adjustment motor group with memory (M28) have one Hall sensor for position measurement.

Electrically adjustable rear bench seat/individual rear seats (special equipment, model 220 only): The adjustment motors for the left rear seat adjustment motor group (M18/1)/right (M18/2) have one Hall sensor each for position measurement.

Position measurement: The signals from these Hall sensors are read in by the left front seat adjustment control module with memory (N32/1)/right front seat adjustment control module with memory (N32/2) and rear seats control module (N25/6, model 220 only), checked for plausibility and counted in the internal position counter. The received Hall pulses are evaluated as positive or negative according to the actuation voltage of the motor. A faultless position measurement is only possible in the normalized condition. It is a prerequisite for the ergonomics default setting function.

Seat calibration function

Function requirements:

- Voltage not too high or too low

- Seat adjustment switch is not pressed.

Through normalization in the left front seat adjustment control module with memory (N32/1)/right front seat adjustment control module with memory (N32/2) the counter counts of the position recognitions of the adjustment motors are linked to the actual positions.

The normalization is a prerequisite for easy entry (model 215 only) and the Ergo function up to 31/05/2001.

Performing normalization: Separate normalization is required for each adjustment motor. Normalization occurs by approaching the respective mechanical stop. Actuation must be carried out in this position for a further 250 ms at least.

Once normalization has been carried out, the control module must be still supplied with voltage for at least 5 seconds in order to ensure a complete and faultless storage in the non-volatile memory (EEPROM).

The mechanical stop relevant to the respective normalization:

| Provision for adjustment | Engine | left |

|---|---|---|

| Seat lengthwise adjustment | M27m1, M28m1 | front |

| Seat height adjustment rear | M27m2, M28m2 | top |

| Seat height adjustment front | M27m3, M28m3 | top |

| Head restraint adjustment | M27m4, M28m4 | DOWN |

| Backrest forward/back | M27m5, M28m5 | front |

| Seat cushion adjustment | M27m6, M28m6 | front |

Seat adjustment collision avoidance function

Function prerequisites:

- Normalizing performed

To avoid collisions of the seat with the seat adjustment switch, the center console, the B-pillar or the roof, the left front seat adjustment control module with memory (N32/1) and right front seat adjustment control module with memory (N32/2) have map controls. In this connection when the motors are actuated the maximum range of adjustment is restricted by means of performance maps stored in the control module and therefore avoid the seat colliding with an obstacle. The following possibilities of a collision can arise during seat adjustment depending on the current seat position:

| Collision possibilities | Actuation 1 | Actuation 2 |

|---|---|---|

| Cushion frame/Seat adjustment switch | Seat cushion angle down | Seat height adjustment down |

| Center console/Seat cushion | Seat lengthwise adjustment to the front | Seat cushion adjustment to the front |

| B-pillar Backrest | Seat forward/back adjustment to rear | Seat backrest adjustment to the rear |

| Roof Head restraint | (Backrest adjustment vertical) | Head restraint upwards |

Blocking detection function

The control modules constantly receive signals from the Hall sensors of the actuated motors. These signals are evaluated for position measurement. If the time intervals in which they enter the control module are too large or are missing completely, blocking is recognized and after t = 2 s actuation is interrupted. Only after the switch is released is a renewed actuation possible in this direction after t = 2 seconds. In comparison an actuation in the opposite direction is possible immediately.

Overload protection function

In order to prevent an overload, the left front seat adjustment control module with memory (N32/1)/right front seat adjustment control module with memory (N32/2) and rear seats control module (N25/6, model 220 only) measures the current of connected and actuated adjustment motors. If one of the currents exceeds a threshold value dependent on the supply voltage (I = 6.3 A - 16 A), the actuation is terminated immediately.

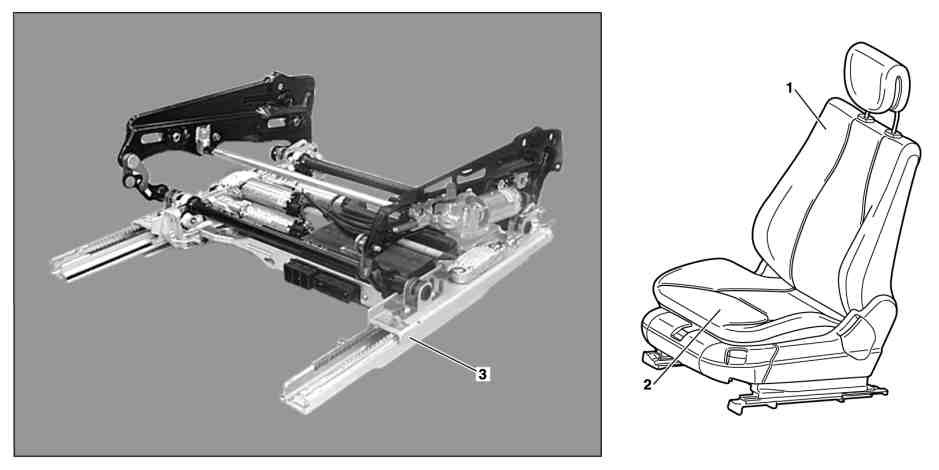

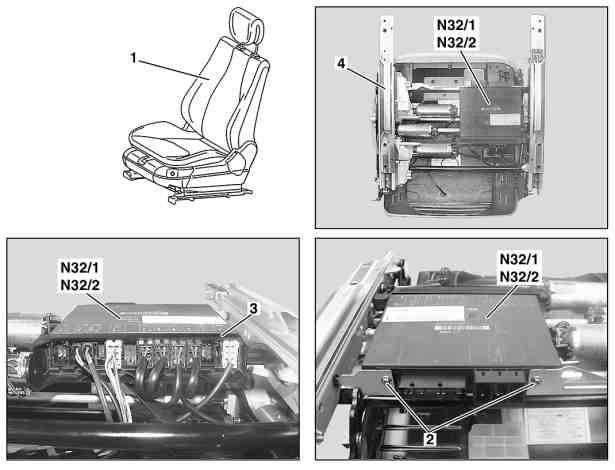

Front seat adjustment motor group

Location of front seat adjustment motor group, shown on model 220:

The six servo DC motors for adjusting the left/right front seat are actuated by the left front seat adjustment control module with memory (N32/1)/right front seat adjustment control module with memory (N32/2). They have one Hall sensor each for position recognition.

Multicontour seat function

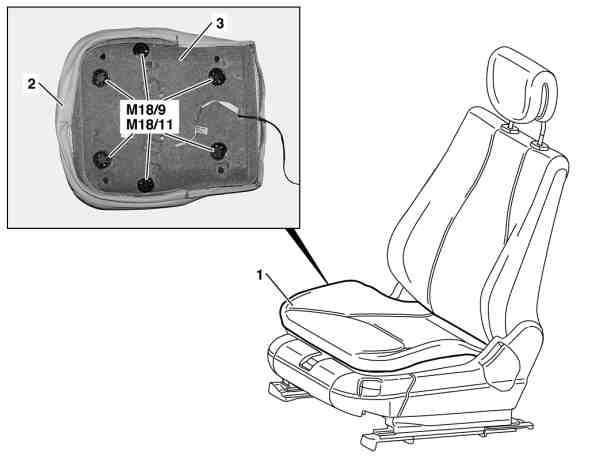

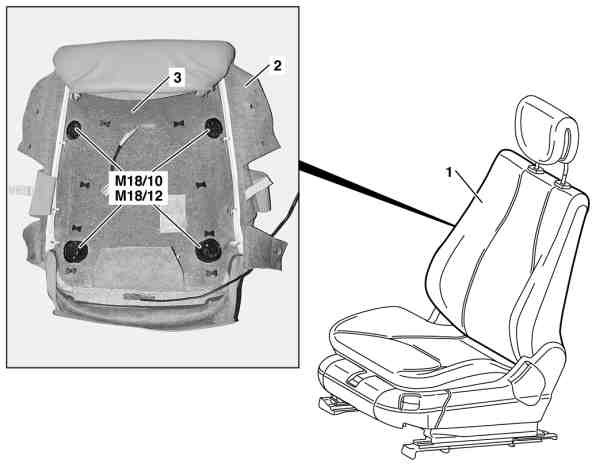

Illustration shows multicontour seat (MCS):

|

The multicontour backrest of the multicontour seat enables individual adjustment of the seat backrest by filling and venting a total of seven air cushions. The contour and surface hardness of the seat backrest can be adjusted independently of each other. For this (combined into groups) two air cushions each are used for the shoulder region (1) and the side region (2), as well as three air cushions for the lumbar region (3). The filling and emptying of the individual air cushion groups is controlled either manually, by means of the operating switch (4) in the seat cushion frame of the respective seat, or automatically by means of the multicontour backrest control module, if the function of dynamic lumbar support has been performed.

The storage and calling up of seat backrest adjustments (air cushion pressure values) is possible with the memory feature. As of 01/06/2001 the switch group has a different design. The modifications are shown in the multicontour switch section below.

Multicontour seat control module

The left front multicontour backrest control module (N32/15)/the right front multicontour backrest control module (N32/16) is located under the respective seat.

The rear multicontour backrest control module (N32/14) is located under the right half of the rear seat bench.

Apart from the actuation/evaluation electronics, pressure control valves (one for each air cushion) are located in all control modules of the multicontour backrests. The air cushions are filled and emptied via these pressure control valves.

The control module reads in the switch conditions of the switch groups of the multicontour backrests, detects the air pressure in the air cushions via piezoresistive pressure sensors, actuates the pressure control valves and receives/sends data from/ to the respective seat control module.

|

|

The multi-contour backrest control module is responsible for:

- Inflating and deflating the multi-contour backrest according to the control actions read in from the multi-contour backrest switches

- Control of dynamic lumbar feature, actuated with multi-contour backrest switch "PULSE" button

- Sensing of actual pressure values in air cushions with piezoresistive pressure sensors

- Generating status data logs on the cushion inflation and transferring these logs to the associated seat control module via a bidirectional, serial interface.

In context with the memory feature:

- Communication with the corresponding control module via interface, particularly regarding storage and recall of stored seat positions

- Setting stored seat positions (pressure values) and other settings when the memory feature is called

Multicontour seat switches

The switch train for the front right (S108)/front left (S109)/rear right (S103)/rear left (S104) multi-contour backrest is located in the corresponding seat, on the outer side of the seat cushion frame.

|

The switch can be used for manually inflating and deflating lumbar cushion group, side backrest cushions and also, on front seats only, shoulder cushion group. An additional switch serves for activating and deactivating the dynamic lumbar adjustment feature.

The switch positions are voltage-coded by means of resistors. The coded voltages are then read in by the corresponding multi-contour backrest control module.

Front seat switch

The switch train in the left/right front seat is equipped with a rocker switch for controlling shoulder cushion and lumbar cushion pulsation. A further rocker switch is used to control the inflation and deflation of the two seat backrest cushions for lateral support. A "PULSE" button is additionally available for switching the dynamic lumbar support on and off.

|

|

|

Rear seat switch

The switch train in the left/right rear individual seat is equipped with a rocker switch for controlling lumbar support cushion pulsation. A further rocker switch is used to control the inflation and deflation of the two seat backrest cushions for lateral support. A "PULSE" button is additionally available for switching the dynamic lumbar support on and off.

|

|

|

Adjust front multicontour seats function

Block diagram for multicontour backrest of front seats:

|

Function requirements:

- Circuit 15c or circuit 15R ON

- respective door open for t >20 s

- Multicontour backrest control module activated:

The left front multicontour backrest control module (N32/15)/right front multicontour backrest control module (N32/16) is activated when it receives an enable signal via a discrete line from the left front seat adjustment control module with memory (N32/1)/right front seat adjustment control module with memory (N32/2).

Manual adjusting of the air cushion groups in the multicontour backrest

The switch conditions of the multicontour backrest switch group in the left front seat (S109)/and right front seat (S108) are read in by the left front multicontour backrest control module (N32/15)/right front backrest control module (N32/16). As a result of this the control module fills and empties the corresponding air cushion groups for as long as the switch is pressed and the function prerequisites are met. At the same time data are exchanged between the relevant control module and the left front seat adjustment control module with memory (N32/1)/right front seat adjustment control module with memory (N32/2) via a discrete line so that storage and subsequent calling up of air cushion adjustments performed manually is possible via the memory feature.

Automatic adjustment of the air cushion groups in the multicontour backrest via the memory feature

The storage and calling up of adjustments performed manually is triggered and controlled by the left front door control module (N69/1)/right front door control module (N69/2). To do this, the door control module exchanges information with the relevant seat control module via CAN messages.

If this receives the request to store, the pressure values of the air cushions conveyed from the multicontour backrest control module are stored in its non-volatile memory. If there is a later request from the door control module to call up memory items, the stored air cushion pressure values are provided to the multicontour backrest control module again. Thereupon this control module fills/empties the air cushions as per the stored values.

As of 01/09/2002 codes 344 and 343 the left front dynamic seat control module (N32/19) and right front dynamic seat control module (N32/22) are responsible for the memory feature.

Manual adjustment of air cushions in the multicontour seat

Function requirements:

- Circuit 15R ON

- Circuit 15 ON

The air cushions of the multicontour backrest can be adjusted manually via the right rear/left rear multicontour backrest switch (S103, S104) and right front/left front multicontour backrest switch group (S108, S109) in the seat cushion frame (on the outside) of the respective seat - right rear/left rear/right front/left front. The adjustments of the air cushions assumed for the shoulder region, the lumbar support region and the seat backrest lateral support are stored in a volatile memory by the left front multicontour backrest control module (N32/15)/ and right front multicontour backrest control module (N32/16) and rear multicontour backrest control module (N32/14)

These values can be stored and called up again via the memory feature in the non-volatile memory of the relevant seat control module.

Manual adjustment of the shoulder region

Manual adjustment of the shoulder region by switch for the shoulder region (S103s4/S104s4).

For driver's and front passenger's seat only. This provision for adjustment is not realized for the individual rear seats.

|

|

Pressing the bottom half of the switch: Air cushions 1 and 2 of the shoulder region are filled in sequence from top to bottom up to the maximum pressure and then emptied again down to the minimum pressure. The process stops as soon as air cushion 2 is at minimum pressure.

Pressing the top half of the switch: The air cushions are filled in the reverse order, thus from the bottom upwards and then emptied (see above).

The transfer pressure p üb and the dwell period tv are adjustable.

Manual adjustment of the lumbar support region

Manual adjustment of the lumbar support region by the lumbar support adjustment switch (S103s3/S104s3) right front/left front lumbar support adjustment switch (S108s3/S109s3).

|

|

Pressing the bottom half of the switch: Air cushions 3, 4, 5 of the lumbar support region are filled from top to bottom up to the maximum pressure and then emptied again down to the minimum pressure. The process stops as soon as air cushion 5 has reached the minimum pressure.

Pressing the top half of the switch: The air cushions are filled in the sequence 5, 4, 3, so from top to bottom and then emptied again (see above).

The transfer pressure p üb and the dwell period tv are adjustable.

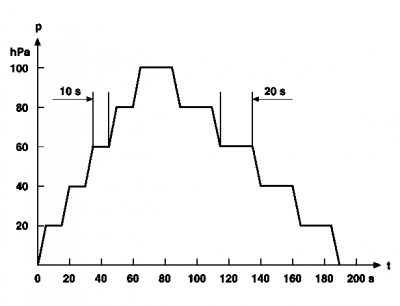

Dynamic lumbar support of multicontour backrest

In order to prevent stresses in the back on longer journeys, the multicontour backrest is equipped with the dynamic lumbar support function. The function is controlled in the relevant seat by the multicontour backrest control module. It is triggered by pressing "PULSE" button on the dynamic lumbar support adjustment switch (S103s1/S104s1/S108s1/S109s1) in the left rear/right rear multicontour backrest switch group (S103, S104) and right front/left front multicontour backrest switch group (S108, S109).

Lumbar support: curvature of spine in lumbar region.

Starting with the air cushion which is currently active the pulsation occurs alternately in the two lumbar support cushions in the sequence lower and upper lumbar (sequence is parameterizable). Filling starts with the active lumbar support cushion up to the next pressure level, unless the upper pressure level has already been reached or exceeded. Each air pressure adjustment is held for approx. 10 seconds before the next condition is assumed. After approx. 8 minutes the program is terminated automatically and the original air cushion pressures are reproduced.

Illustration shows function sequence for dynamic lumbar support:

First of all the three lumbar support air cushions of the multicontour backrest are emptied. After this the center air cushion is filled in stages up to the maximum pressure and then emptied again down to the minimum pressure (see Figure). This process (cycle) is repeated for a second time. After this the function is terminated by the control module. The function can be terminated at any time by pressing the switch again.

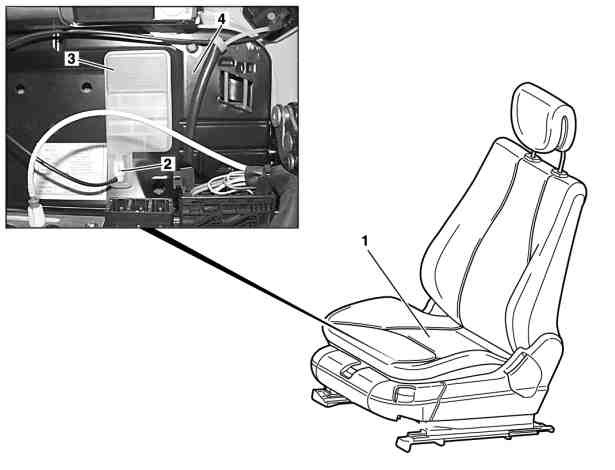

Dynamic seat function

Dynamic seat (FDS) as of 01/09/2002 function with codes 433 and 434

Illustration shows Dynamic seat (FDS) as of 01/09/2002 with codes 433 and 434:

|

|

All the following provisions for adjustment are explained on the driver's seat and also apply to the front passenger's seat.

The dynamic seat comprises the functions:

- Memory multicontour backrest (MMKL)

- Dynamic side support

Memory multicontour backrest (MMKL)

The multicontour backrests enable individual adjustment of the respective seat backrest by filling and emptying up to three air cushion groups:

- Air cushion for the upper and lower shoulder region

- Air cushion for the respective side region

- Air cushion for the upper and lower lumbar support region

The "Dynamic lateral support" function is switched on or off by pressing the FDS "DYNAMIC" button and is controlled by the left front dynamic seat control module (N32/19). If the function is activated, this is displayed by an LED in the FDS "DYNAMIC" button. The left front dynamic seat control module (N32/19) adjusts after that a corresponding basic pressure in the lateral support cushions and, when cornering, ensures better retention in the lateral support by temporarily adding pressure to the lateral support cushions on the outside of the curve. This essentially happens as a function of the instantaneous speed and the lateral acceleration. This information comes from the traction systems control module (N47) and is transmitted by central gateway control module (N93) from CAN-C (engine compartment) to CAN-B (interior). If the data for the FDS function fail for more than 2 seconds, the function is switched off and remains switched off. The extent and speed with which the lateral support cushions for the driver's and front passenger's seat are filled can be adjusted via the second operating level of the instrument cluster (A1).

Priority sequence of the functions

The priorities are set in the sequence:

- Priority 1 Lumbar support

- Priority 2 Shoulder region (not for individual rear seats)

- Priority 3 Lateral support

- Priority 4 Dynamic lumbar support and dynamic lateral support (front seats only)

When pressing multiple rocker switches at the same time, only the adjustment movement with the highest priority is executed.

Abort criteria

All functions are interrupted if there is overvoltage or undervoltage. The relevant function is not performed if a valve has overheated or there is a leakage fault.

Limit stop emptying

If the end point is reached after the lumbar support wave has passed, the inactive air cushion is emptied for as long as the switch is pressed, but for a maximum period of 1 minute.

Control functions

The adjusted specified pressures of the individual cushion areas are controlled by the left front dynamic seat control module (N32/19) and right front dynamic seat control module (N32/22) in each case in a manner which is unnoticeable for the customer provided that the function conditions for manual adjustment are met.

The contour and surface hardness of the seat backrest can be adjusted manually via the:

- Switch group for right front multicontour backrest (S108)

- Switch group for left front multicontour backrest (S109)

- the "dynamic lumbar support" function.

Dynamic lateral support (driver's/front passenger's seat)

Function requirements:

- Circuit 15R ON

- Circuit 15 ON

- No undervoltage or overvoltage

- No overtemperature sensor

- No leakage fault in the lateral support region

Sport (stage 1): Extra pressure is applied more quickly and more intensely to the lateral support cushions on the outside of the curve.

Comfort (stage 2): Extra pressure is applied slowly and less intensely to the lateral support cushions on the outside of the curve.

Definitively the following control modules are involved in the dynamic seat:

- left front dynamic seat control module (N32/19)

- right front dynamic seat control module (N32/22)

- central gateway control module (N93)

- traction systems control module (N47)

Background functions

In the lumbar support region the cushions are arranged overlapping and consequently coupled in their function during the wave sequence. As only one air cushion is active in each case, the adjacent cushions are considered as not active i.e. empty. The following background functions are necessary to ensure this.

Idle time emptying (optional)

While the pressure is kept constant in the active air cushion (residence time), the adjacent non-active air cushions are emptied.

Backgrounds emptying

If the active air cushion is emptied, then the residual pressure in the adjacent non-active air cushions is also reduced, as soon as the air cushions have the same pressure.

The subsequent regulation follows, for example, in the event of pressure deviations caused by:

- The respective person sitting in or leaning on the seat

- Leakage in the seat inflators

- Temperature changes caused by heated seats, insolation, air conditioning and user warmth

Sudden changes in pressure which arise due to the person sitting in on leaning on the seat are adjusted immediately and in a comfort- orientated manner. The control parameters that are listed can be programmed using diagnosis.

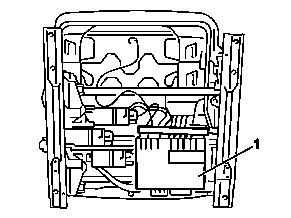

Dynamic seat control module

The left front dynamic seat control module (N32/19) and right front dynamic seat control module (N32/22) is located in the respective seat backrests on the driver's/front passenger's side.

|

|

Tasks:

- To fill and empty the multicontour backrest in accordance with the requirements read in by the switch

- Control of dynamic lumbar support, triggered by the multicontour backrest switch with the inscription: "PULSE"

- Control of dynamic lateral support triggered by the "DYNAMIC" switch

- Detection of the actual pressure values of the air cushions by piezoresistive pressure sensors and keeping these pressures constant

- Reading in the voltage-coded MMKL adjusting switch and the DYNAMIC switch

- Communication with the interior CAN via the respective seat control module

- Adjusting the stored pressure values when calling up the memory feature and storing the actual contours

- Cutout of the respective function if the pressure control valve responsible has overheated

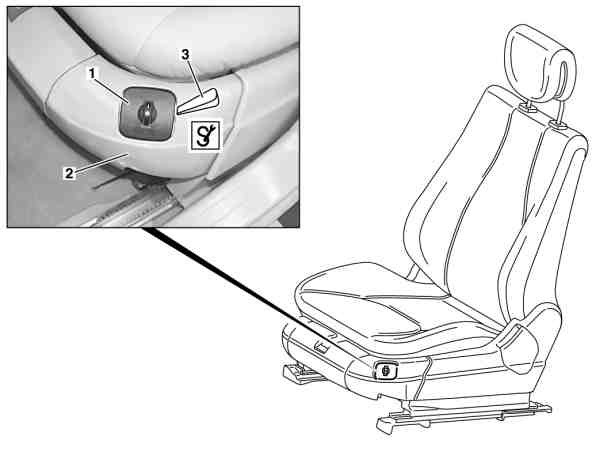

Dynamic seat switch

The right/left front DS [FDS] switch group (S108/1,S109/1) in each case is located under the front multicontour backrest switch group on the seat cushion.

The switch turns the dynamic lateral support function on and off.

|

|

Manual adjustment of air cushions in the dynamic multicontour seat

All the following provisions for adjustment are explained on the driver's seat and also apply to the front passenger's seat.

Manual adjustment of the shoulder region as of 01/09/2002 with codes 433 and 434

Air cushions 1 and 2 of the shoulder region are coupled and are adjusted with the shoulder region adjustment switch (S109s4).

When the rocker switch is pressed towards "+" or "-" the backrest contour in the shoulder region is changed by filling/emptying the air cushions.

This provision for adjustment is not realized for the individual rear seats.

Manual Adjustment of the lumbar support region as of 01/09/2002 with codes 433 and 434

The lumbar support region of the seat is operated by the lumbar support adjustment switch (S109s3). When the cross rocker is pressed towards "+" or "-" the backrest contour changes in the lumbar support region by filling/emptying the air cushion which is currently active.

When the cross rocker of the bottom half of the switch is pressed the backrest contour in the lumbar support region is changed sequentially. First, the lower air cushion is filled/emptied again and then the upper air cushion is filled. Only one air cushion is actuated actively in this process. This sequence starts with the air cushion which has just become active.

When the cross rocker of the top half of the switch is pressed the sequence is the same as when the bottom half of the switch is pressed, only in the reverse order. The upper air cushion is emptied first and then the lower air cushion is filled.

Dynamic lumbar support

All the following provisions for adjustment are explained on the driver's seat and also apply to the front passenger's seat.

In order to prevent stresses in the back on longer journeys, the dynamic seat multicontour backrest is equipped with the dynamic lumbar support function. The function is controlled in the relevant seat by the multicontour backrest control module. It is triggered by pressing "PULSE" button on the dynamic lumbar support adjustment switch (S103s1/S104s1/S108s1/S109s1) in the left rear/right rear multicontour backrest switch group (S103, S104) and right front/left front multicontour backrest switch group (S108, S109).

Lumbar support: curvature of spine in lumbar region.

Starting with the air cushion which is currently active the pulsation occurs alternately in the two lumbar support cushions in the sequence lower and upper lumbar (sequence is parameterizable). Filling starts with the active lumbar support cushion up to the next pressure level, unless the upper pressure level has already been reached or exceeded. Each air pressure adjustment is held for approx. 10 seconds before the next condition is assumed. After approx. 8 minutes the program is terminated automatically and the original air cushion pressures are reproduced.

Illustration shows function sequence of dynamic lumbar support as of 01/09/2002 with codes 433 and 434:

|

|

The function is controlled by the left front dynamic seat control module (N32/19). The program is started and stopped by the dynamic lumbar support adjustment switch (S109s1) "PULSE" button. The active function is displayed by illuminating the LED in the switch. After the switch is pressed, first the air pressures of the air cushion in the lumbar support region are stored by the left front dynamic seat control module (N32/19).

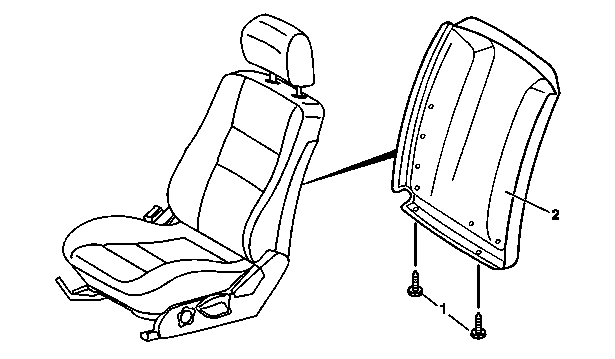

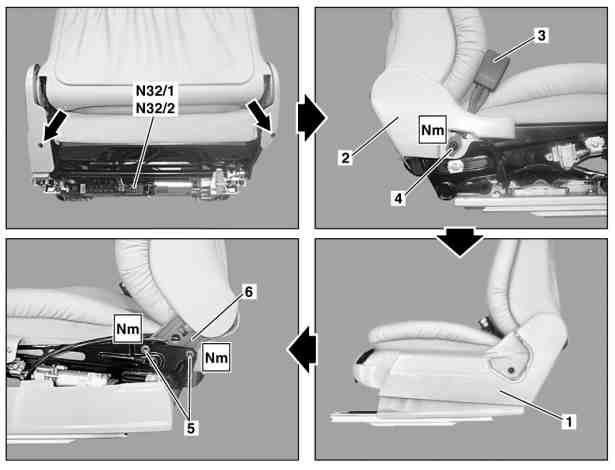

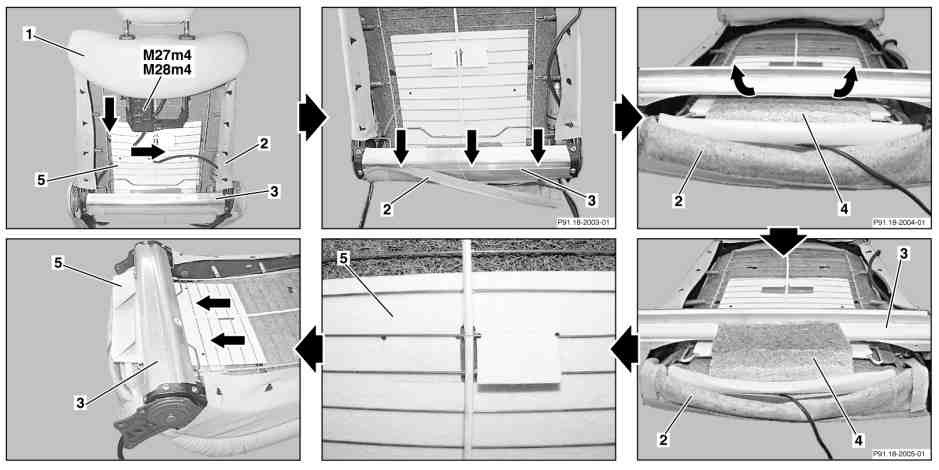

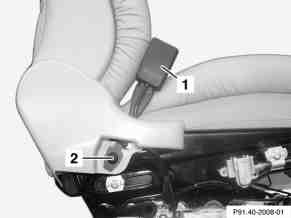

Remove/install front seat backrest seat-back lining

|

|

- Slide the front seat forwards with the longitudinal adjustment mechanism

- Slide backrest forwards with the inclination adjustment mechanism

- Unscrew screws (1)

- Pull seat-back lining (2) down and take off. Installation: slide seat-back lining into top of backrest.

- Install in the reverse order

|

|

|

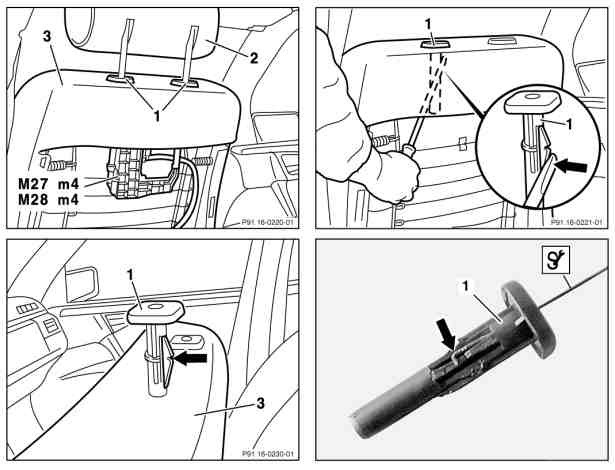

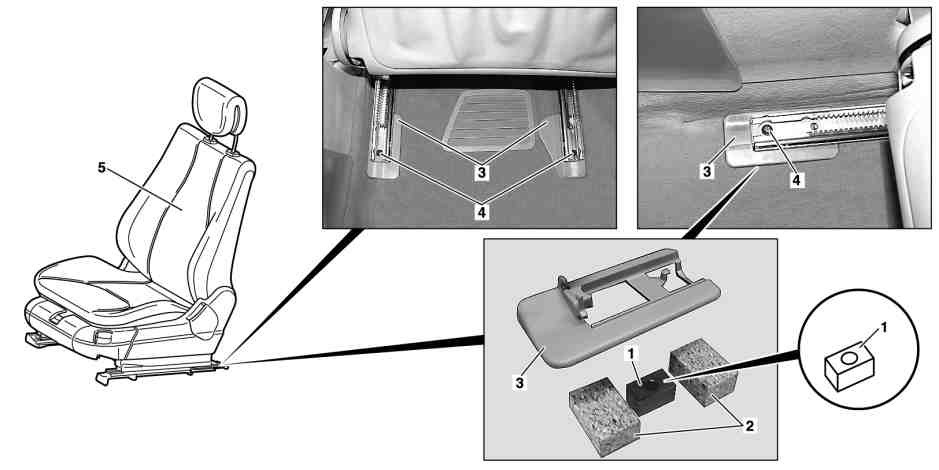

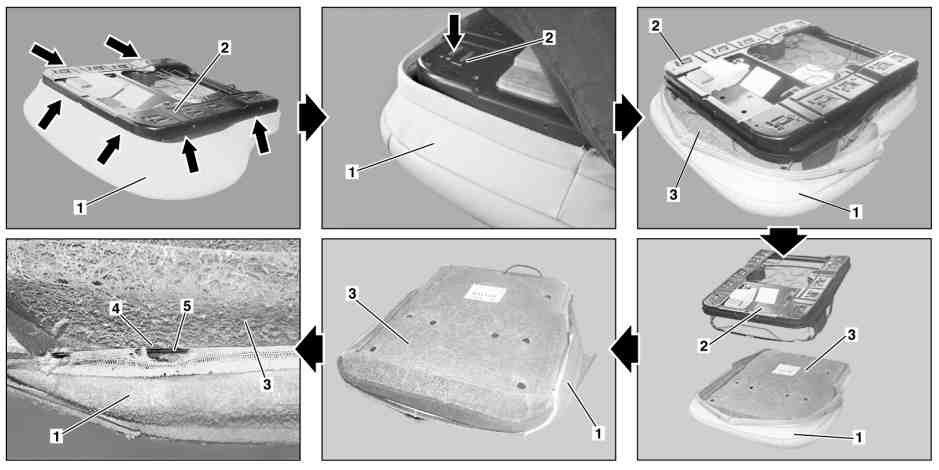

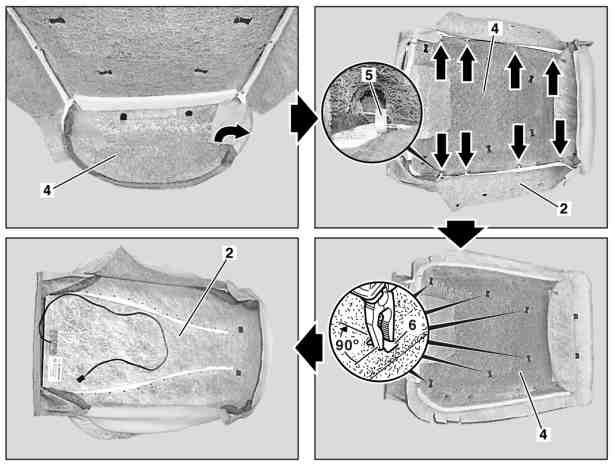

Remove and install headrest guide on front seat

|

|

Remove:

- Remove head restraint (2)

- Remove tensioning element (seat-back lining) from front seat backrest

- Remove head restraint raise/lower motor (M27m4/M28m4). Push motor to right first and then remove downwards.

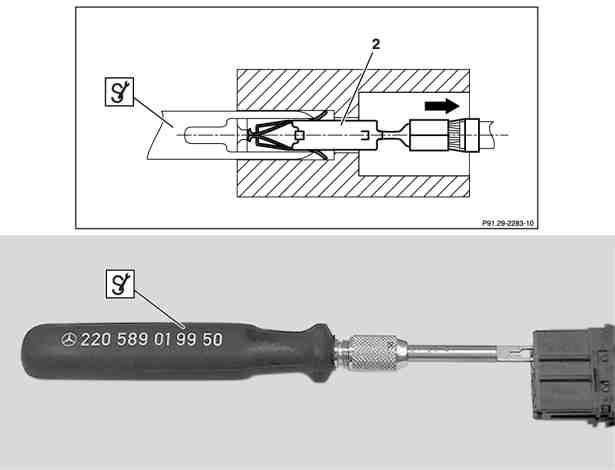

- Release catch at head restraint guide (1) using screwdriver. Push back catch (arrow) at head restraint guide (1) using screwdriver and pull head restraint (1) out upwards.

- Release catch at head restraint guide (1) using pulling hook. Insert pulling hook into top of head restraint guide (1), push back catch and pull out head restraint upwards.

Install:

- Insert head restraint guide (1) into backrest frame of front seat backrest (3). Do not damage backrest upholstery. Catch (arrow) must point towards rear.

- Engage head restraint guide (1) in backrest frame of front seat backrest (3)

- Install head restraint raise/lower motor (M27m4/M28m4). Insert motor facing upwards and then push to left until it engages in backrest frame.

- Fit seat-back lining to front seat backrest (3)

- Install head restraint (2)

| Error Code | Generated By | Description |

|---|---|---|

| B1203 | ESA-FL - Electronic seat adjustment front left | Hall sensor of component M27m4 (Head restraint raise/lower motor) is faulty |

Facelift head restraint motor A2209700026 fits both sides.

Note: due to normalization requirement, when installing new motor the new motor may be need to be moved manually to the position of the old motor, otherwise it may be encountered that motor is not able to move the full distance.

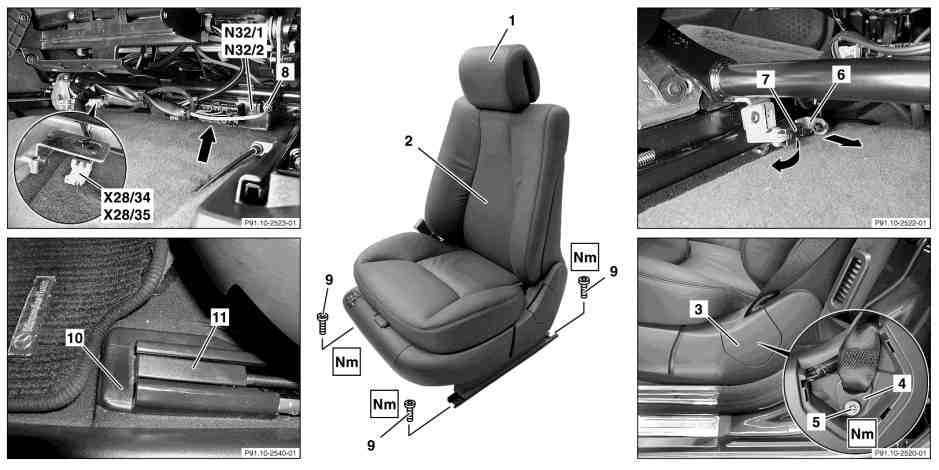

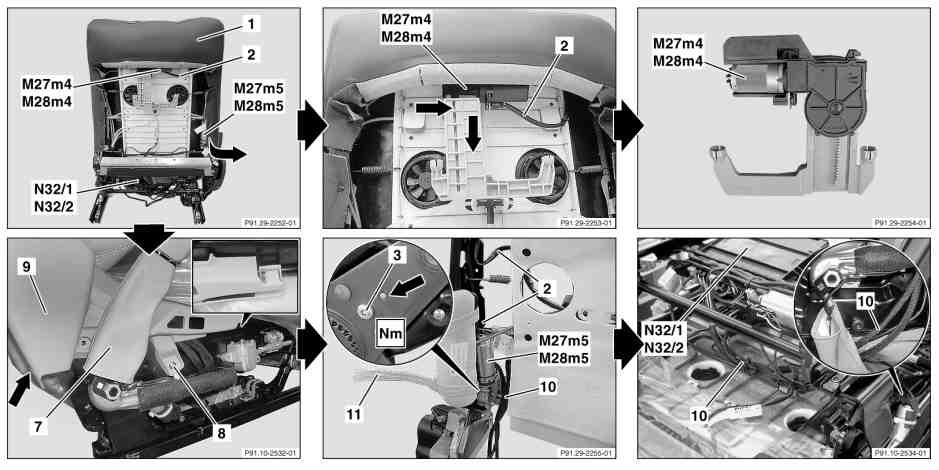

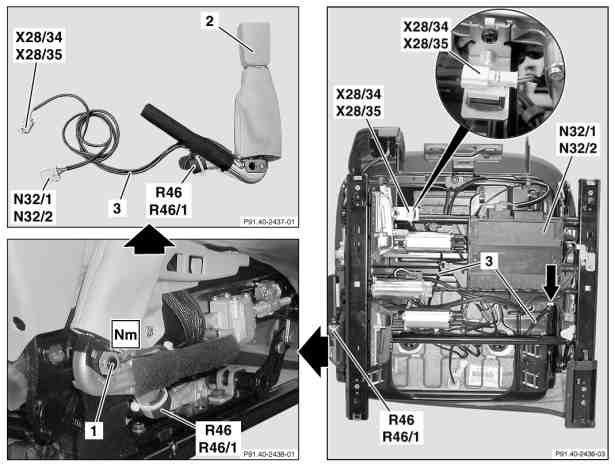

Remove/install front seat (as of 01/09/2002)

|

|

- Switch off ignition, remove ignition key (vehicles without KEYLESS-GO, code 889).

- Switch off engine, remove transmitter key from vehicle (with KEYLESS-GO, code 889). Keep transmitter key out of transmitter range.

- Remove head restraint (1)

- Adjust front seat (2) to front. Move front and rear seat cushions all the way up. Move backrest into upright position.

- Remove cover (3) at rear side paneling

- Remove screw/bolt (5) at belt end fitting (4). Installation: When screwing on, ensure that belt end fitting (4) remains mobile.

- Remove rear screws/bolts (9) from seat rails. Remove cover (11) from seat rail.

- Turn retaining clamp (7) at Bowden cable in direction of transmission tunnel and remove

- Unhook grommet (6) with Bowden cable from bracket

- Position front seat (2) to rear

- Remove front screw/bolt (9) from seat rails. Remove cover (11) from seat rail.

- Pry off pneumatic line plug coupling (8) with open end wrench, size 7. Slightly incline seat toward rear in vehicle.

- Detach connecting coupling (see arrow) from front seat adjustment control unit with memory, left (N32/1), right (N32/2). Slightly incline seat toward rear in vehicle.

- Disconnect 2-pin driver seat connecting point buckle emergency tensioning retractor connector (X28/34), 2-pin front passenger seat connecting point buckle emergency tensioning retractor connector (X28/35). Slightly incline seat toward rear in vehicle.

- Remove seat rail final cover (10) from seat rails

- Lift front seat (2) and remove

- Install in the reverse order

- Check function of seat adjustment mechanism

Torque specifications:

- Bolt to seat runner: 45 Nm

- Screw on belt end fitting: 30 Nm

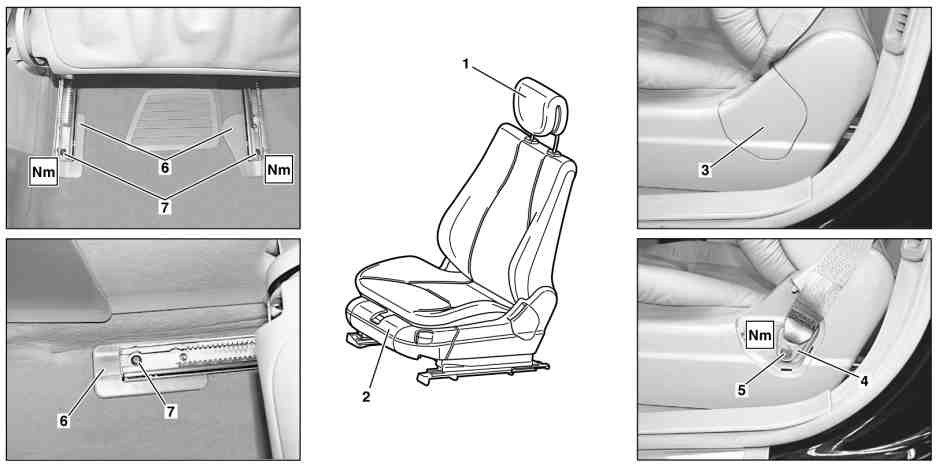

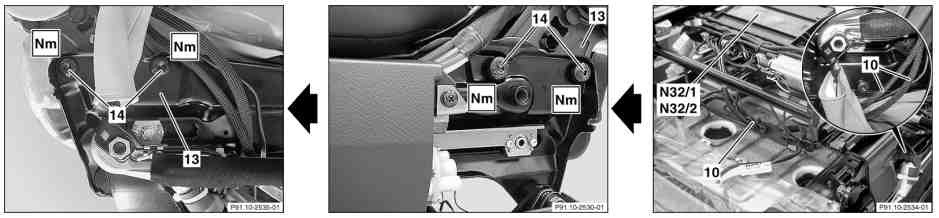

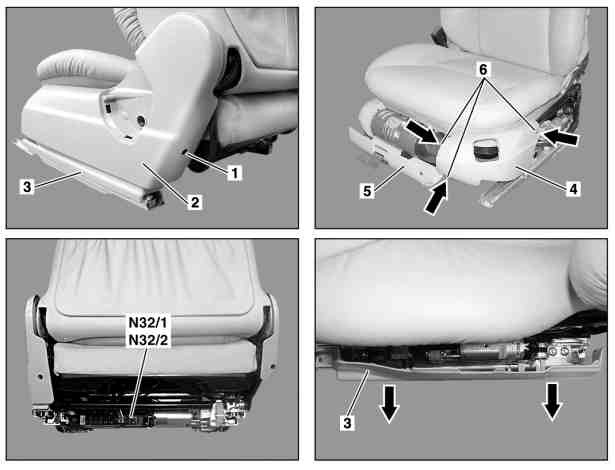

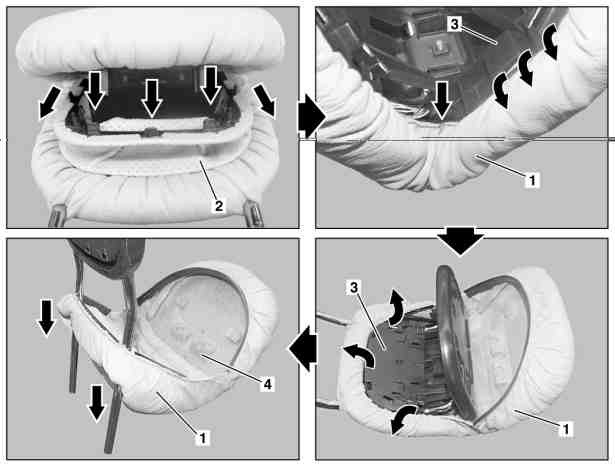

Remove/install front seat (up to 31/08/2002)

|

|

|

|

- Remove head restraint (1)

- Adjust front seat (2) to front

- Remove cover (3) above belt end fitting (4)

- Remove bolt (5) from seat belt end fitting (4)

- Remove screws (7) at the back of the seat rails

- Remove covers (6) at rear of seat rails

- Position front seat (2) to rear

- Remove screws (7) at the front of the seat rails

- Remove covers (6) at front of seat rails

- Detach plug connection from pneumatic line (8) and left front seat connector block (X55/3) and right front seat connector block (X55/4) from front seat cushion. Disconnect plug connection on pneumatic line (8) with 7 mm open end wrench.

- Detach retaining clamp (9) for Bowden cable seat belt height adjustment at seat adjustment mechanism (10) in direction of arrow

- Lift front seat (2) and remove

- Install in the reverse order

Torque specification:

- Bolt to seat runner: 50 Nm (up to 30/11/2001), 45 Nm (as of 01/12/2001)

- Screw on belt end fitting: 30 Nm

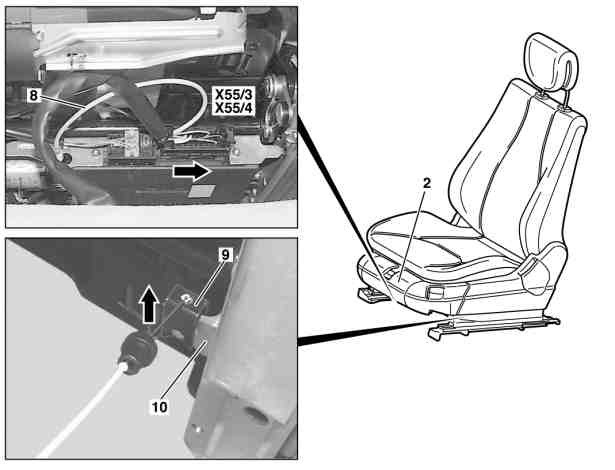

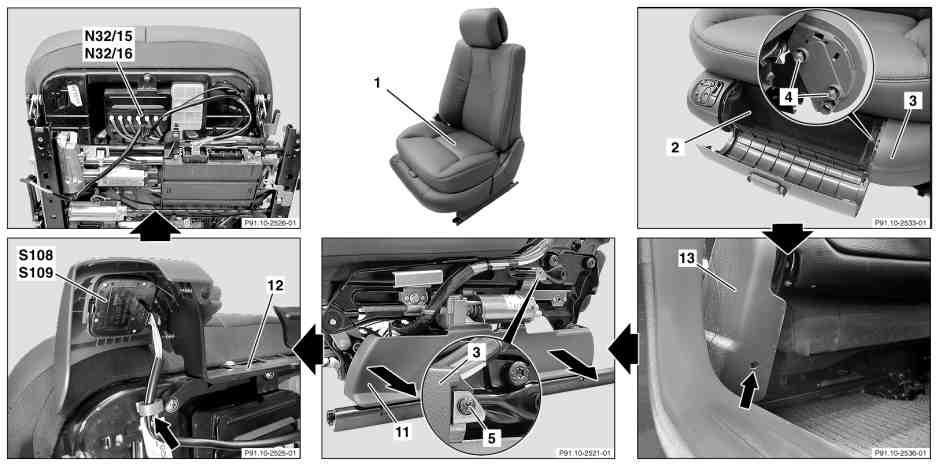

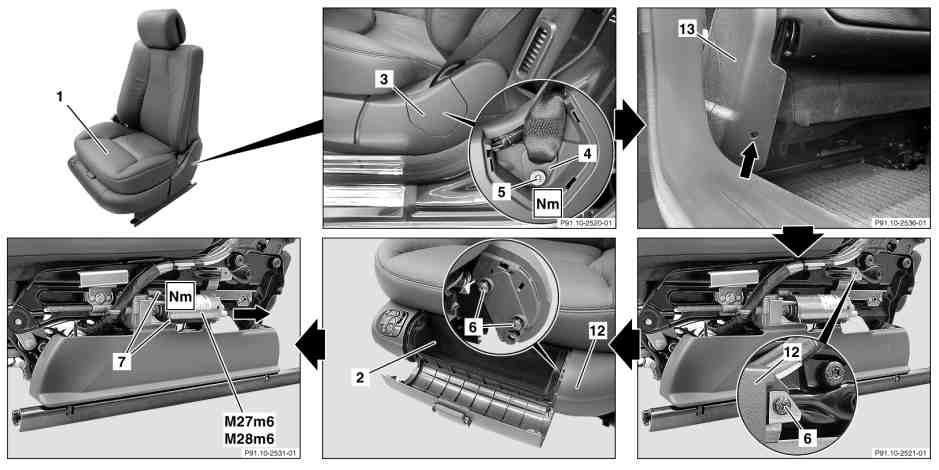

Remove/install front seat backrest (as of 01/09/2002)

|

|

|

|

- Remove front seat

- Open flap on stowage compartment (2)

- Unclip stowage compartment (2)

- Remove fire extinguisher (for fire extinguisher code 682)

- Remove bolts (4, 2 pieces) on the left side paneling (3)

- Unscrew and remove bolt (see arrow) on the belt end fitting cover (12)

- Unscrew bolt (5) on the left side paneling (3) (see enlarged detail)

- Detach left side paneling (3) in direction of travel

- Unclip lower side paneling (11) in the direction of the arrow (for the multicontour backrest for the driver seat code 404b and front passenger seat code 405b).

- Remove multicontour backrest control unit on front seat (for the multicontour backrest for the driver seat code 404b and front passenger seat code 405b).

- Remove bolt (see arrow) and bolt (8) on seat belt buckle (9) cover

- Unclip retaining lug (see enlarged detail) and remove seat belt buckle (9) cover

- Expose and detach electrical line (10) from the front seat backrest (1) to the front seat adjustment control unit with memory, on the left (N32/1), right (N32/2). Installation: Ensure that routing is chafing-free.

- Remove bolt (14, 2 pieces) on the right and left side from the backrest fitting (13)

- Remove front seat backrest (1) from seat adjustment mechanism

- Install in the reverse order

- Perform function test for the seatrest function

Torque specifications:

- Bolt on backrest fitting: 35 Nm

Remove/install front seat backrest (up to 31/08/2002)

|

|

- Remove front seat

- Remove screw (arrow) on paneling (1)

- Remove trim panel (1)

- Remove bolt (4) and remove seat belt buckle (3)

- Remove screw (arrow) on paneling (2)

- Remove trim panel (2)

- Separate pneumatic line connector for lumbar support air cushion

- Remove multicontour backrest control unit from front seat (on vehicles with driver seat multicontour backrest, code 404b and passenger seat, code 405b).

- Disconnect backrest and head restraint adjustment connector from left front seat adjustment control unit with memory (N32/1) and right front seat adjustment control unit with memory (N32/2)

- Unscrew bolt (5, 2 each) from left and right backrest fitting (6)

- Remove front seat backrest from the seat adjustment mechanism

- Install in the reverse order

Torque specifications:

- Bolt at backrest fitting: 35 Nm (up to 30/11/2001 and as of 01/12/2001)

- Screw/nut on front seat belt buckle: 30 Nm

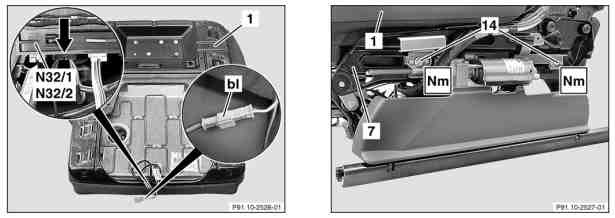

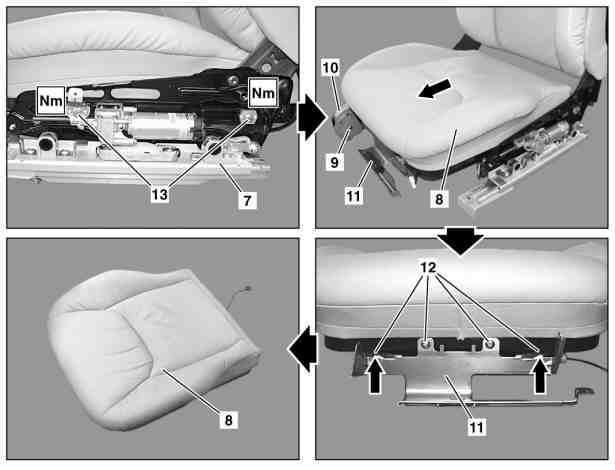

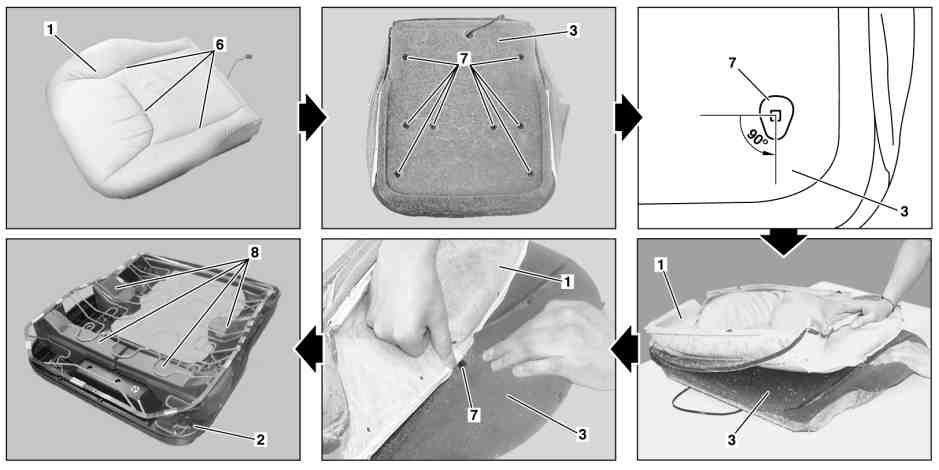

Remove/install driver seat cushion (as of 01/09/2002)

|

|

|

|

- Remove front seat. Move seat cushion all the way up and to center position so that rear bolt (14) on belt buckle is accessible.

- Open flap in stowage compartment (2)

- Unclip stowage compartment (2)

- Remove fire extinguisher (with fire extinguisher, code 682).

- Unscrew bolts (4, 2 each) from left side paneling (3)

- Unscrew bolt (see arrow) at rear of paneling (13) on belt end fitting and remove

- Unscrew bolt (5) from left side paneling (3)

- Remove left side paneling (3) in direction of travel

- Unclip bottom side paneling (11) in direction of arrow (with driver seat multicontour backrest, code 404b, passenger seat, code 405b).

- Remove pneumatic lines from lumbar support control valve

- Remove connector coupling from left front multicontour backrest switch group (S109), right front multicontour backrest switch group (S108) (on driver seat multicontour backrest code 404b, passenger seat code 405b or left dynamic seat including multicontour seat code 433, right code 434).

- Remove omega clip (see arrow) from seat cushion frame

- Remove connector coupling from dynamic seat switch (on left dynamic seat incl. multicontour seat code 433, right code 434).

- Remove multicontour backrest control unit from front seat (with driver seat multicontour backrest, code 404b, passenger seat, code 405b).

- Unscrew stowage compartment retaining frame (12) from cushion frame

- Unscrew bolt (14, 2 each) and slide seat cushion (1) on seat adjustment mechanism (7) toward front. Do not yet remove seat cushion (1) from seat adjustment mechanism.

- Disconnect blue connector on fan motor (bl) (for code (401a) front comfort seat, incl. seat heating and seat ventilation).

- Remove coupling for seat cushion heater (see arrow in magnifying glass) from left front seat adjustment control unit with memory (N32/1), right front seat adjustment control unit with memory (N32/2) (for front comfort seats, incl. seat heating and seat ventilation vehicles, code 401a or right and left front seat heaters or code 873).

- Remove seat cushion (1) from seat adjustment mechanism (7)

- Install in the reverse order

- Check seat adjustment for proper function

Torque specifications:

- Bolt, seat cushion to seat adjustment mechanism: 15 Nm

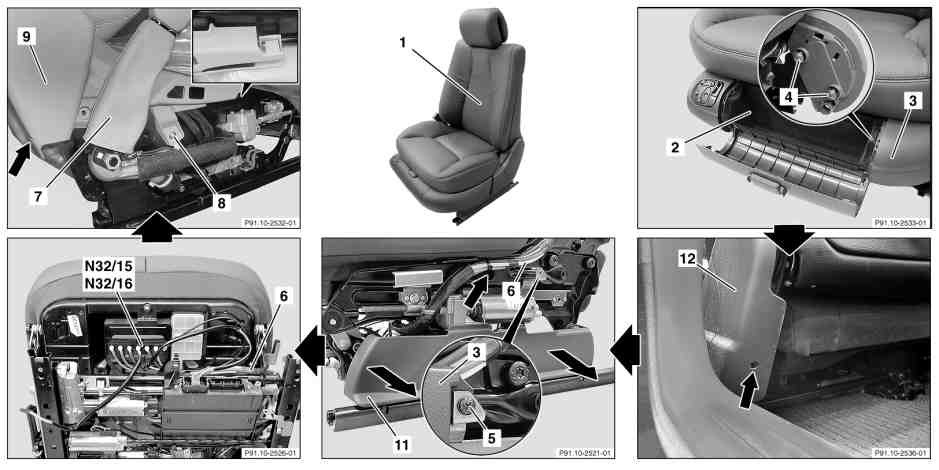

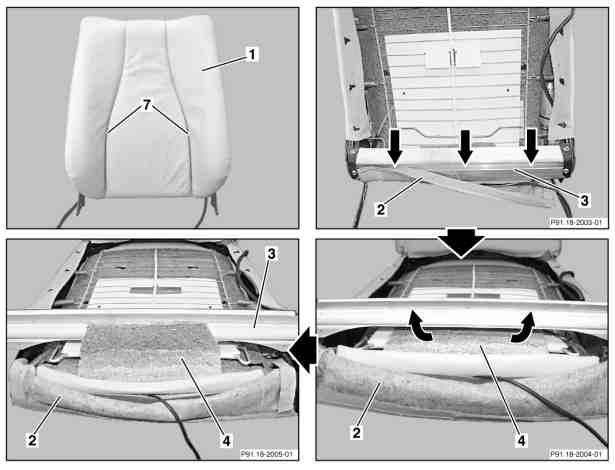

Remove/install driver seat cushion (up to 31/08/2002)

|

|

|

|

- Remove front seat

- Remove screw (1) and remove paneling (2)

- Open cap (5) and remove fire extinguisher (with fire extinguisher, code 682).

- Remove screws (6, arrows) and remove paneling (4) and cap (5)

- Pull off paneling (3) in direction of arrow. Ensure that retaining lugs are not damaged.

- Disconnect connector from seat cushion heater on left front seat adjustment control unit with memory (N32/1) and right front seat adjustment control unit with memory (N32/2).

- Remove multicontour backrest control unit from front seat (with driver seat multicontour backrest, code 404b, passenger seat, code 405b).

- Remove screw (9) and remove paneling (10)

- Remove screws (13) and remove seat cushion (8) forwards from the seat adjustment mechanism

- Remove screws (12, arrows) from the seat cushion (8) and remove bracket (11) from the seat cushion (8)

- Install in the reverse order

Torque specifications:

- Bolt, seat cushion to seat adjustment mechanism: 15 Nm (up to 30/11/2001 and as of 01/12/2001)

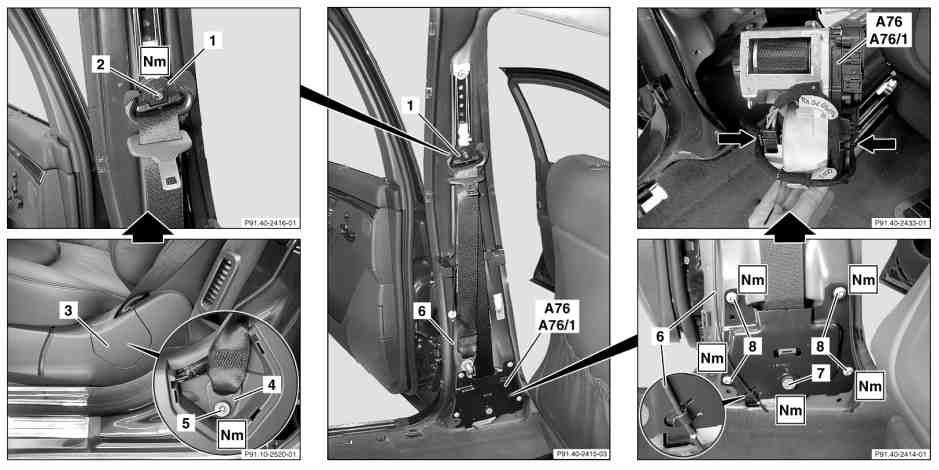

Remove/install seat belt (front seat) as of 01/09/2002

|

|

- Move front seat as far forward as possible with backrest upright

- Switch ignition off, withdraw ignition key

- Switch engine off, remove transmitter key from vehicle. With KEYLESS-GO code 889 keep transmitter key outside transmission range.

- Remove paneling on B-pillar

- Remove cover (3) of belt end fitting (4) and undo screw (5)

- Unscrew screw (2) from seat belt guide bracket (1)

- Unhook Bowden cable (6) on cover plate (see magnifying glass at bottom right)

- Undo TORX screw (8, 4 pieces) on cover plate. Installation: Tighten screw (7) to torque rating.

- Undo screw (7) from cover plate. Installation: Tighten screw (7) finger-tight only to cover plate.

- Detach 6-pin coupling and 2-pin coupling (see arrows) of left front reversible emergency tensioning retractor (A76), and right front reversible emergency tensioning retractor

- (A76/1) Remove left front reversible emergency tensioning retractor (A76), and left front reversible emergency tensioning retractor (A76/1). Installation: Note different version (left/right) of seat belt emergency tensioning retractor and correct seating in cover plate. Noises from the automatic belt reel when rolling up belt are normal. The only available response to negative customer feedback regarding unacceptable noise levels is to replace the seat belt assembly with emergency tensioning retractor in its entirety. On no account should oil or grease be used to help eliminate noise. Automatic belt retractors that have been opened are no longer under warranty!

- Install in the reverse order

- Carry out diagnosis

Torque specification:

- Belt end fitting screw: 30 Nm

- Screw/nut on front seat belt guide bracket: 30 Nm

- Screw on front automatic belt reel: 30 Nm

- Bolt, emergency tensioning retractor cover plate to B-pillar: 10 Nm

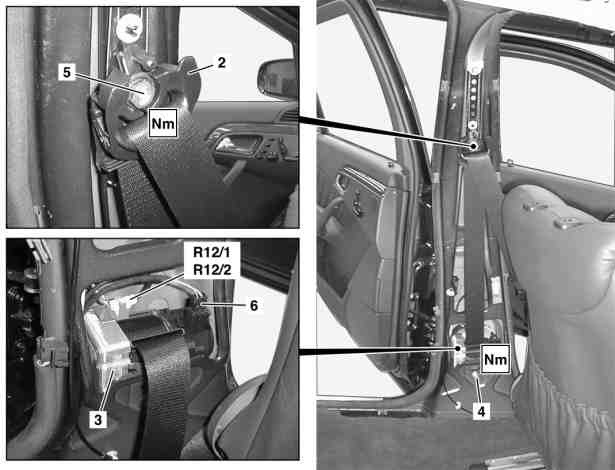

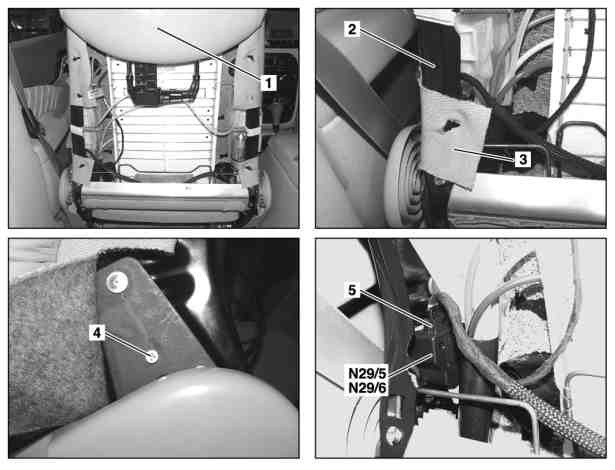

Remove/install seat belt (front seat) up to 31/08/2002

|

|

|

|

- Move front seat as far forward as possible with backrest upright

- Switch ignition off, withdraw ignition key

- Switch engine off, remove transmitter key from vehicle. With KEYLESS-GO code 889 keep transmitter key outside transmission range.

- Remove paneling on B-pillar

- Remove cover of belt end fitting (1) and undo screw

- Unscrew nut (5) from seat belt guide bracket (2)

- Release coupling on driver ETR [GUS] ignition squib (R12/1), passenger-side ETR [GUS] ignition squib (R12/2) and coupling (6)

- Remove screw (4) at automatic seat belt retractor (3)

- Remove automatic belt reel (3). Installation: Note different version (left/right) of seat belt emergency tensioning retractor and correct seating in catch. Noises from the automatic belt reel when rolling up belt are normal. The only available response to negative customer feedback regarding unacceptable noise levels is to replace the seat belt assembly with emergency tensioning retractor in its entirety. On no account should oil or grease be used to help eliminate noise. Automatic belt retractors that have been opened are no longer under warranty! If the seat belt with emergency tensioning retractor has been replaced, the defective unit must be disposed of properly.

- Install in the reverse order

- Carry out diagnosis

Torque specification:

- Belt end fitting screw: 30 Nm

- Screw/nut on front seat belt guide bracket: 30 Nm

- Screw on front automatic belt reel: 30 Nm

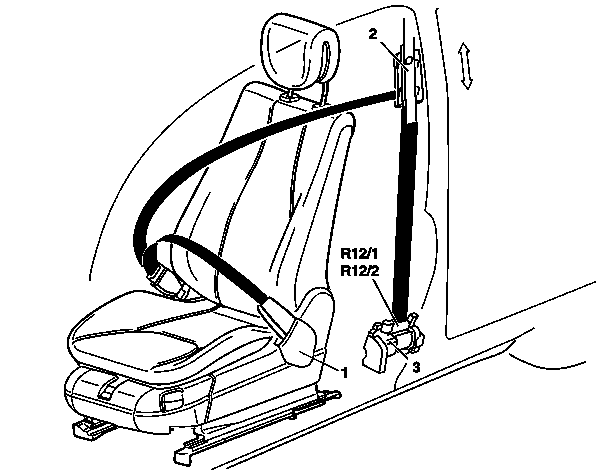

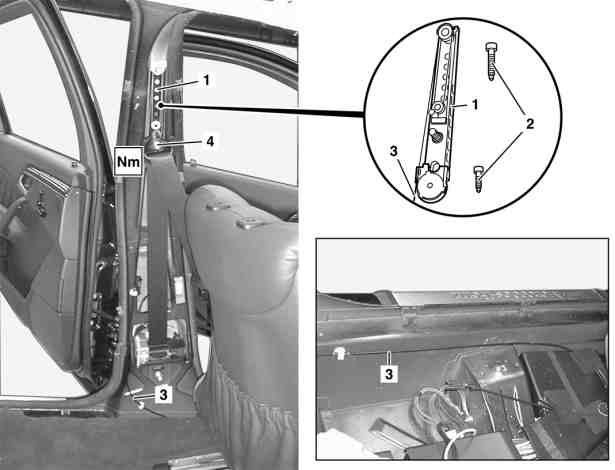

Seat belt height adjustment mechanism (front seat) removal and installation

|

|

- Remove front seat

- Remove paneling on B-pillar

- Unclip Bowden cable (3) using Omega clip

- Unclip Bowden cable (3) from deflection in cable duct. Lift floor lining at left front until the deflection for the Bowden cable (3) in the cable duct can be easily accessed.

- Disassemble the Bowden cable (3) up to the belt height adjuster (1)

- Undo nut from seat belt guide bracket (4)

- Undo screw (2, 2 pieces) on belt height adjuster (1)

- Install in the reverse order

Torque specification:

- Screw/nut on front seat belt guide bracket: 30 Nm

- Screw on front automatic belt height adjuster: 25 Nm

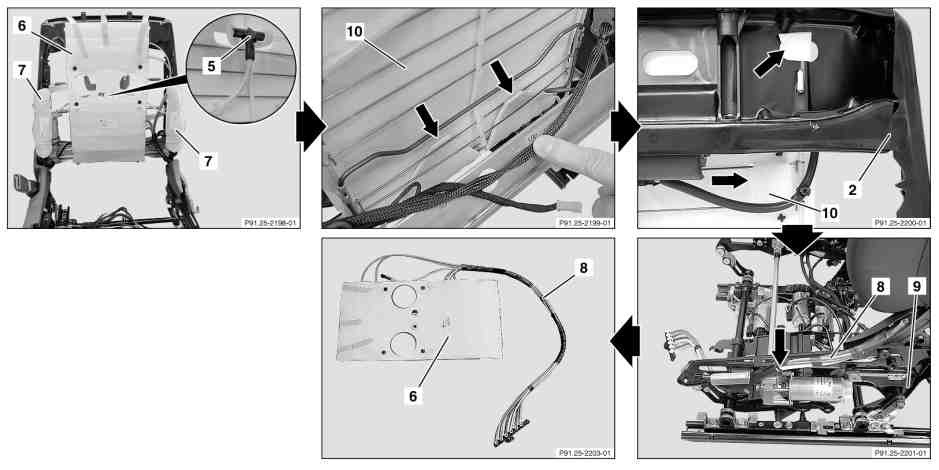

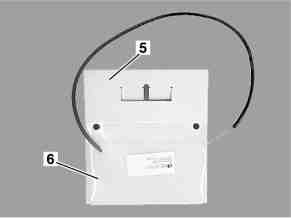

Remove/install front seat multicontour backrest control module (code 404b/405b)

|

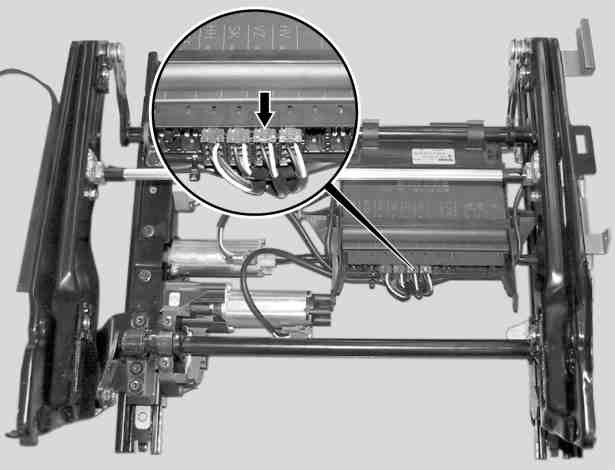

- Remove front seat

- Unscrew screw (2) and remove frame (3)

- Remove multicontour backrest, front left (N32/15) or right (N32/16)

- Expose control module connecting cable (6) and disconnect from front seat adjustment control module (see arrow)

- Expose switch group connecting cable (7) and disconnect from multicontour backrest switch group

- Open catch (5) and remove pneumatic line connecting rail (1). Open catch (5) using small screwdriver (see arrow).

- Unclip black pneumatic line with diam. of 4 mm (sw) to overpressure reservoir (4) (only if seat cushion or backrest has to be removed).

- Install in the reverse order

- Check multicontour seat backrest for proper function

Remove/install front seat adjustment mechanism

|

|

- Remove front seat backrest (1)

- Remove driver's seat cushion (2)

- Remove front seat control module

- Remove front seat adjustment motor group (seat cushion) - up to 30/06/2001.

- Remove front seat adjustment motor group (seat cushion) (only for front and rear seat cushion and front seat forward and backward) - as of 01.07.2001.

- Remove front seat adjustment motor group (seat cushion) (only for seat cushion forward and backward) - as of 01/07/2001 and up to 31/08/2002, as of 01/09/2002.

- Install in the reverse order

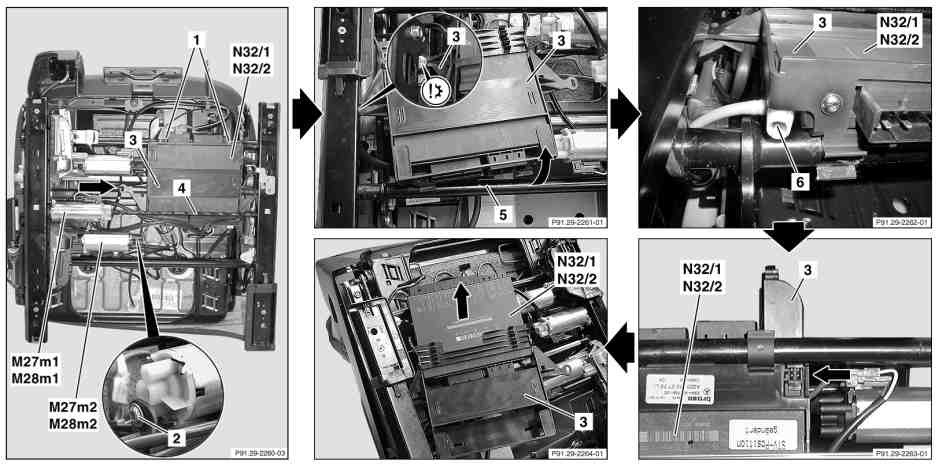

Remove/install front seat control module (as of 01/07/2001)

|

|

- Remove front seat

- Remove all connectors to front and rear side of left (N32/1) and right (N32/2) front seat adjustment control module with memory

- Slacken tie straps (see arrow) at control module bracket lug (3). Installation: Use new tie straps.

- Unscrew bolt (1, 2 pcs.) at front of left (N32/1) and right (N32/2) front seat adjustment control module with memory

- Unscrew bolt (2, see magnification) from rear up/down motor (M27m2, M28m2)

- Detach flexible shaft (4) from forward/back motor (M27m1, M28m1)

- Carefully release front control module bracket (3) from transverse rod (5), (see arrow) until both plastic retaining clamps on underside of control module bracket (3) have been unclipped. Control module bracket (3) is fixed to the seat frame with a rivet (see magnification).

- Unclip pneumatic line (6) at front left (N32/1) and right (N32/2) side of left front seat adjustment control module with memory