Trunk: Difference between revisions

Ricebubbles (talk | contribs) (Moved Section Trunk to new Section WIS 88.50 Trunk/Boot) |

Ricebubbles (talk | contribs) (Rearranged with better sub sections.) |

||

| Line 1: | Line 1: | ||

==Opening the trunk lid== | ==Description - Trunk/Boot== | ||

A minimum height clearance of 6 ft. (1.85 m) is required to open the trunk lid. | TBD | ||

==Functions - Trunk/Boot== | |||

TBD | |||

==Issues - Trunk/Boot== | |||

Common issues relating to the trunk/boot lid functions are; | |||

* [[WIS 88.52 Retractable Trunk Lid Grip (RTG)| Hissing Sound on Trunk Opening or Closure]] | |||

* Broken or Failed Pneumatic Actuators. | |||

* Cracked or broken pneumatic lines. | |||

* [[WIS 88.52 Retractable Trunk Lid Grip (RTG)| Cannot remove the actuator rod to get the locking mechanism out of the trunk]] | |||

* Leakage of water into the trunk because the power closing assist fails to pull the lid closed completely. | |||

* Cannot open the trunk when the battery is dead. | |||

==EMERGENCY OPENING - Trunk/Boot== | |||

===Trunk Opening with a Dead Battery=== | |||

A completely dead battery prevents the boot lid from being electrically opened. A jump start is not possible if you cannot access the battery as the W220 does not have accessible jump ports. | |||

If the trunk is locked and the battery is dead try these techniques for opening the trunk lid. | |||

<!-- http://mbworld.org/forums/s-class-w220/328173-dead-battery-cant-get-trunk-inside-car-how-jump-start-help.html --> | |||

'''Solution 1:''' Extract the mechanical key from the [[SmartKey]] and use it to open the trunk. | |||

'''Solution 2:''' If the mechanical key doesn't work you may have to charge the battery prior to jump starting the car. | |||

* Pull the carpet back from the top under the front passenger side dash. | |||

* Behind the Styrofoam insulation there is an aluminum plate. | |||

* Unscrew the 3-4 bolts to get to the positive terminal. | |||

* Hook up a charger and charge the battery as long as possible. | |||

* After a while you should be able to start the car. | |||

* If the trunk still will not open reset it by removing the 20A yellow fuse from under the rear right passenger seat fuse box. | |||

* Leave it out for about 5 mins. | |||

* Then put it back in and then try to open the Trunk. | |||

* The Trunk should now open. | |||

===Trunk Opening Without a Key=== | |||

To open the trunk if for some reason it cannot be opened using smartkey or mechanical key, you can use this method which will cause '''only minor damage''' of the lid covering. | |||

* Detach the licence plate from the trunk lid covering. | |||

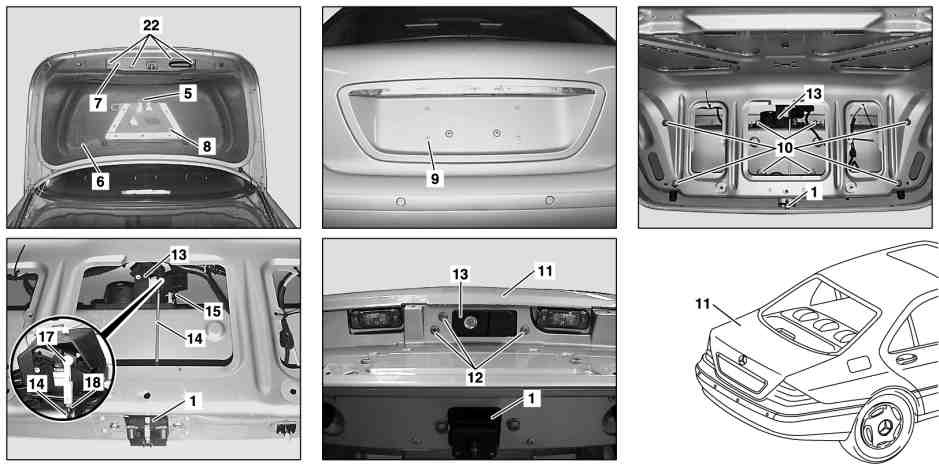

* The covering (9) is a big plastic part mounted on the lid. Remove the covering: | |||

** Pre-facelift: | |||

*** You will see two screws in the middle of covering (9). Remove them. | |||

*** You have to remove covering by force using plastic molding remover tool. Note, that there are 7 bolts (10) that are tightened from the inside to hold the covering (9) in place. '''You will damage plastic housing for these bolts in the covering.''' However, it is very common to see these housings already damaged. Furthermore, the covering holds to the lid just fine only using the two central screws. | |||

** Facelift: | |||

*** Note, that there are 8 clips (10) and one bolt in the center tightened from the inside that hold the covering (9) in place. '''You have to drill off the head of center bolt holding the covering.''' This bolt is not crucial, since the covering holds to the lid just fine using only the clips. | |||

* After covering is removed you will see three T30 torx bolts (12) holding the trunk lid handle. Unscrew them. | |||

* Push the whole trunk lid handle inside through the hole while pushing the button. | |||

* You will hear the pop noise. Trunk lid is open. | |||

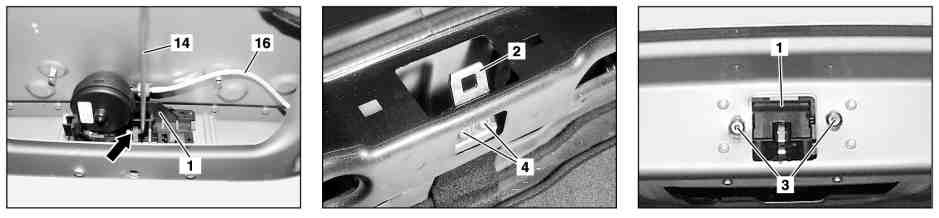

* In case the release rod (14) that connects the trunk lid lock (1) to the trunk lid handle (13) is disconnected, you can use a needled nose pliers to release the rod and open the trunk. | |||

{| | |||

|[[File:W220_trunk_lid_covering_removed.jpg|thumb|none|Trunk lid covering removed (pre-facelift).]] | |||

|[[File:W220_trunk_lid_handle_unscrewed.jpg|thumb|none|Trunk lid handle pushed in (pre-facelift).]] | |||

|[[File:W220_trunk_lid_release_lever.jpg|thumb|none|Trunk lid release rod disconnected.]] | |||

|} | |||

==Normal Opening - Trunk/Boot== | |||

'''WARNING:''' A minimum height clearance of 6 ft. (1.85 m) is required to open the trunk lid fully. | |||

===Unlocking and opening the trunk lid using SmartKey=== | ===Unlocking and opening the trunk lid using SmartKey=== | ||

| Line 11: | Line 67: | ||

===Opening the trunk lid from the inside=== | ===Opening the trunk lid from the inside=== | ||

You can open the trunk from the inside if the vehicle is stationary. | You can open the trunk from the inside if the vehicle is stationary. | ||

The switch is located on the driver's door. | The switch is located on the driver's door. | ||

| Line 27: | Line 84: | ||

===Opening the trunk lid using emergency release=== | ===Opening the trunk lid using emergency release=== | ||

Some W220 S-Class vehicles have an emergency release button so that you do not get trapped inside. | |||

[[File:W220_trunk_lid_emergency_release_button.jpg]] | [[File:W220_trunk_lid_emergency_release_button.jpg]] | ||

| Line 53: | Line 111: | ||

Vehicles with [[KEYLESS-GO]]: If the vehicle was previously centrally locked, the trunk lid will lock automatically after closing it. | Vehicles with [[KEYLESS-GO]]: If the vehicle was previously centrally locked, the trunk lid will lock automatically after closing it. | ||

==Closing the trunk | ==Normal Closing - Trunk/Boot== | ||

'''WARNING:''' Do not place the [[SmartKey]] in the open trunk. You may lock yourself out. | |||

Vehicles with [[KEYLESS-GO]]: To prevent a possible inadvertent lockout, the trunk lid will open automatically if a SmartKey with KEYLESS-GO is recognized inside the vehicle or in the trunk. | |||

Vehicles with [[KEYLESS-GO]]: To prevent a possible inadvertent lockout, the | |||

trunk lid will open automatically if a SmartKey with KEYLESS-GO is recognized inside the vehicle or in the trunk. | |||

===Closing the trunk lid using handle=== | ===Closing the trunk lid using handle=== | ||

| Line 67: | Line 124: | ||

|} | |} | ||

In addition to handle (1), facelift vehicles can be closed using extending handle built into the trunk lid handle (2). | In addition to handle (1), facelift vehicles can be closed using the extending handle (Retractable Trunk Grip (RTG)) built into the trunk lid handle (2). | ||

Push the trunk lid down gently at the extending handle (2) until it engages into the lock. | Push the trunk lid down gently at the extending handle (2) until it engages into the lock. | ||

The extending handle (2) is retracted after a few seconds. | The extending handle (2) is retracted after a few seconds. | ||

The power closing assist automatically ensures that the lid is pulled closed completely. | The power closing assist automatically ensures that the lid is pulled closed completely. | ||

==Trunk | ==Remote Closing - Trunk/Boot== | ||

On vehicles with option code [[Data_Card#881_-_REMOTE_TRUNK_LOCKING|881 - REMOTE TRUNK LOCKING]] | On vehicles with option code [[Data_Card#881_-_REMOTE_TRUNK_LOCKING|881 - REMOTE TRUNK LOCKING]] | ||

the trunk lid can be closed by a press of button. | the trunk lid can be closed by a press of button. | ||

If the trunk lid comes into contact with an object while closing (e.g. luggage that has been piled too high) in the upper motion | If the trunk lid comes into contact with an object while closing (e.g. luggage that has been piled too high) in the upper motion sequence, the closing procedure is stopped and the trunk reopens slightly. | ||

sequence, the closing procedure is stopped and the trunk reopens slightly. | |||

The trunk lid opening height can be limited when transporting goods on a roof rack (e.g. presence of an MB sport luggage container). | The trunk lid opening height can be limited when transporting goods on a roof rack (e.g. presence of an MB sport luggage container). | ||

When activated, the trunk lid opens to approximately the height of the roof edge. | When activated, the trunk lid opens to approximately the height of the roof edge. | ||

You can activate the limiting opening height of trunk lid using the control system. | You can activate the limiting opening height of trunk lid using the control system. | ||

The closing procedure can be stopped at any time by pressing the trunk lid closing switch (on the driver's door), | The closing procedure can be stopped at any time by pressing the trunk lid closing switch (on the driver's door), the trunk lid closing switch (1), or the "trunk lid unlock" button on the [[SmartKey]]. | ||

the trunk lid closing switch (1) or the "trunk lid unlock" button on the [[SmartKey]]. | |||

===Closing from the outside === | ====Closing from the outside ==== | ||

[[File:W220_trunk_lid_closing_switch.jpg|thumb|none|Trunk lid closing button (without KEYLESS-GO)]] | [[File:W220_trunk_lid_closing_switch.jpg|thumb|none|Trunk lid closing button (without KEYLESS-GO)]] | ||

| Line 92: | Line 149: | ||

Press trunk lid closing switch (1) briefly. The trunk lid closes. | Press trunk lid closing switch (1) briefly. The trunk lid closes. | ||

On vehicles with trunk lid closing system and [[KEYLESS-GO]], | On vehicles with trunk lid closing system and [[KEYLESS-GO]], you can close the trunk lid and lock the vehicle simultaneously using the second button on the switch. | ||

you can close the trunk lid and lock the vehicle simultaneously using the second button on the switch. | |||

{| | {| | ||

| Line 105: | Line 161: | ||

The turn signals flash three times to confirm locking. | The turn signals flash three times to confirm locking. | ||

=== Closing from the inside === | ==== Closing from the inside ==== | ||

The trunk lid can be closed from the inside using the opening switch if the vehicle is stationary. | The trunk lid can be closed from the inside using the opening switch if the vehicle is stationary. | ||

| Line 113: | Line 169: | ||

To interrupt the closing procedure release remote trunk lid switch (2). | To interrupt the closing procedure release remote trunk lid switch (2). | ||

==Trunk | ==Restricting Access with Additional Locking Mechanism - Trunk/Boot== | ||

Vehicles equipped with option code [[Data_Card#884_-_TRUNK_LID_ADDITIONAL_LOCKING_MECHANISM_.28HZS.29|884 - TRUNK LID ADDITIONAL LOCKING MECHANISM (HZS)]] | Vehicles equipped with option code [[Data_Card#884_-_TRUNK_LID_ADDITIONAL_LOCKING_MECHANISM_.28HZS.29|884 - TRUNK LID ADDITIONAL LOCKING MECHANISM (HZS)]] | ||

have a function permitting the separate locking of the trunk using the mechanical key. | have a function permitting the separate locking of the trunk using the mechanical key. | ||

If present, this feature can permit you to deny any unauthorized person access to the trunk by locking the trunk | If present, this feature can permit you to deny any unauthorized person access to the trunk by locking the trunk separately and leaving the [[SmartKey]] less the mechanical key with the vehicle. | ||

separately and leaving the [[SmartKey]] less the mechanical key with the vehicle. | |||

To verify the presence of this feature, use the mechanical key to lock the trunk and then attempt to open the trunk by pressing the trunk lid button after the vehicle has been centrally unlocked with the SmartKey. | |||

The lock is located next to the recessed handle. | The lock is located next to the recessed handle. | ||

| Line 205: | Line 260: | ||

|} | |} | ||

==Locking Mechanism Actuator== | ==Locking Mechanism Actuator - Trunk/Boot== | ||

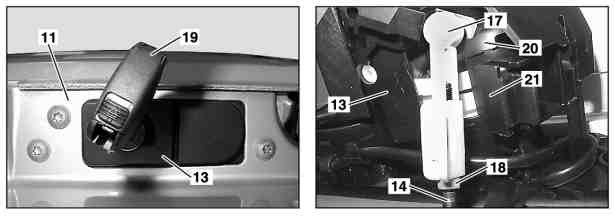

W220 trunk lid actuator is pneumatically controlled and can have some or all of the following functions: | ===Functions - Trunk Locking Mechanism Actuator=== | ||

The W220 trunk lid actuator is pneumatically controlled and can have some or all of the following functions: | |||

* Auto opening (all vehicles) | * Auto opening (all vehicles) | ||

* Auto or self closing (vehicles with option code 881) | * Auto or self closing (vehicles with option code 881) | ||

| Line 213: | Line 269: | ||

The positive and negative pressures required for the pneumatic control of the Trunk/Boot Lid functions are generated by the [[Pneumatic System Equipment (PSE) Pump|Pneumatic System Equipment (PSE) Pump.]] | The positive and negative pressures required for the pneumatic control of the Trunk/Boot Lid functions are generated by the [[Pneumatic System Equipment (PSE) Pump|Pneumatic System Equipment (PSE) Pump.]] | ||

===Part Numbers - Trunk Locking Mechanism=== | ===Part Numbers - Trunk Locking Mechanism Actuator=== | ||

* Whole Assembly - Trunk Locking Mechanism Actuator 220 750 06 84, 2207500684. | * Whole Assembly - Trunk Locking Mechanism Actuator 220 750 06 84, 2207500684. | ||

[[File:Boot Trunk Lid Locking Mechanism Actuator.JPG|300px|center]] | [[File:Boot Trunk Lid Locking Mechanism Actuator.JPG|300px|center]] | ||

| Line 223: | Line 279: | ||

[[File:W220 Trunk Locking Mechanism Actuator Air Servo White.JPG|200px|center]] | [[File:W220 Trunk Locking Mechanism Actuator Air Servo White.JPG|200px|center]] | ||

== | == DIY Procedures - Trunk/Boot == | ||

=== DIY 1 - Removing Trunk Lid Lining === | |||

== DIY - Removing Trunk Lid Lining == | |||

<!-- http://www.benzworld.org/forums/w220-s-class/2532833-repair-part-220-750-0684-trunk.html --> | <!-- http://www.benzworld.org/forums/w220-s-class/2532833-repair-part-220-750-0684-trunk.html --> | ||

| Line 267: | Line 299: | ||

|} | |} | ||

== DIY - Removing Trunk Lining == | === DIY 2 - Removing Trunk Lining === | ||

<!-- http://www.benzworld.org/forums/w220-s-class/2000609-less-than-20-usd-gps-antenna.html --> | <!-- http://www.benzworld.org/forums/w220-s-class/2000609-less-than-20-usd-gps-antenna.html --> | ||

{| | {| | ||

| Line 287: | Line 319: | ||

|} | |} | ||

== | === DIY 3 - Welding trunk lid covering holes === | ||

Trunk lid has 7 (pre-facelift) or 8 (facelift) holes which are used to attach the trunk covering (9) to the trunk lid. | Trunk lid has 7 (pre-facelift) or 8 (facelift) holes which are used to attach the trunk covering (9) to the trunk lid. | ||

It is common to see these holes being a source for moisture and rust inside the trunk lid. | It is common to see these holes being a source for moisture and rust inside the trunk lid. | ||

| Line 320: | Line 330: | ||

|} | |} | ||

==DIY - Repair of Broken | === DIY 4 - Repair of Broken Trunk Lid Actuator 01=== | ||

With thanks to BenzWorld member 'subscriber' for posting an excellent description of his repair of a broken locking mechanism pneumatic actuator. | With thanks to BenzWorld member 'subscriber' for posting an excellent description of his repair of a broken locking mechanism pneumatic actuator. | ||

| Line 328: | Line 338: | ||

See http://www.benzworld.org/forums/w220-s-class/2532833-repair-part-220-750-0684-trunk.html | See http://www.benzworld.org/forums/w220-s-class/2532833-repair-part-220-750-0684-trunk.html | ||

==DIY - Repair of Broken | === DIY 5 - Repair of Broken Trunk Lid Actuator 02=== | ||

See [[WIS 88.52 Retractable Trunk Lid Grip (RTG)]] for a DIY repair of a broken actuator. | See [[WIS 88.52 Retractable Trunk Lid Grip (RTG)]] for a DIY repair of a broken actuator. | ||

==DIY - Repair of | === DIY 6 - Repair of Trunk Lid Actuator Pneumatic Solenoid Valves=== | ||

In the Actuator there is a double solenoid valve which distributes the pneumatic pressure to the relevant actuator depending on the required result. | |||

In the | |||

The exact description of which coil does what has yet to be determined and wasn't necessary for a thorough clean and bench test. It is something like the following: (Reference: HECK function on [[Pneumatic System Equipment (PSE) Pump]]. | The exact description of which coil does what has yet to be determined and wasn't necessary for a thorough clean and bench test. It is something like the following: (Reference: HECK function on [[Pneumatic System Equipment (PSE) Pump]]. | ||

| Line 339: | Line 348: | ||

* When the Boot/Trunk Lid is commanded to open either by remote control on the key fob, by pressing the Boot/Trunk Lid button, or by pulling the internal Boot/Trunk Lid release button on the driver's door, the PSE HECK port provides +ve pressure (27KPa or 4psi) to the Boot/Trunk Lid Solenoid Valve Assembly and hence to the Small Black Actuator or "Hockey Puck" which opens the locking latch, thus releasing the lid which fully opens. +ve Pressure is also applied to the RTG Handle, which extends the Handle. After all this is finished the pneumatic line returns to atmospheric pressure. | * When the Boot/Trunk Lid is commanded to open either by remote control on the key fob, by pressing the Boot/Trunk Lid button, or by pulling the internal Boot/Trunk Lid release button on the driver's door, the PSE HECK port provides +ve pressure (27KPa or 4psi) to the Boot/Trunk Lid Solenoid Valve Assembly and hence to the Small Black Actuator or "Hockey Puck" which opens the locking latch, thus releasing the lid which fully opens. +ve Pressure is also applied to the RTG Handle, which extends the Handle. After all this is finished the pneumatic line returns to atmospheric pressure. | ||

===DIY Clean and Regrease | === DIY 7 - Clean and Regrease Trunk Lid Actuator Pneumatic Solenoid Valves=== | ||

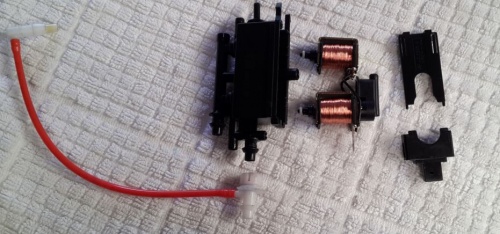

Once the Boot/Trunk Lid Pneumatic Actuator is removed from the vehicle it can be dismantled on the work bench. See [[WIS 88.52 Retractable Trunk Lid Grip (RTG)]] for the removal method. | Once the Boot/Trunk Lid Pneumatic Actuator is removed from the vehicle it can be dismantled on the work bench. See [[WIS 88.52 Retractable Trunk Lid Grip (RTG)]] for the removal method. | ||

* Press in the two small plastic tabs and the Pneumatic Solenoid Valve Assembly can be with drawn. | * Press in the two small plastic tabs and the Pneumatic Solenoid Valve Assembly can be with drawn. | ||

| Line 351: | Line 360: | ||

[[File:W220 Trunk Lid Actuator Pneumatic Solenoid Valves 02.JPG|300px|center]] | [[File:W220 Trunk Lid Actuator Pneumatic Solenoid Valves 02.JPG|300px|center]] | ||

* Before reassembly check the electrical pneumatic solenoid valves. | |||

* Reassemble in the reverse order but apply silicon dielectric or vacuum grease to the pneumatic seals before assembly. | |||

=== DIY 8 - Check Electrical Trunk Lid Pneumatic Solenoid Valves=== | |||

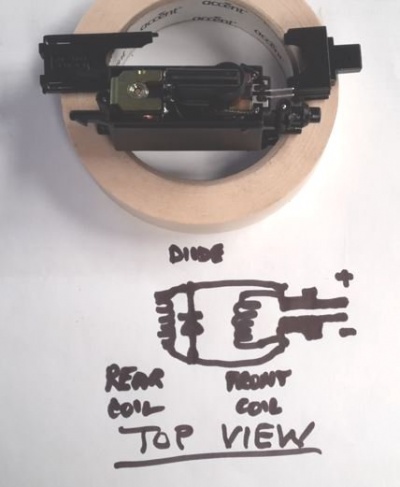

The electrical circuit diagram is very simple with the two coils just connected in parallel. A diode is also connected across the coils to reduce current surge when the coils are switched off. (Here is the theory: The magnetic energy stored in energised coils can generate a large spark across the operating switch when it is opened and consequently burn the electrical contacts in the switch. A diode provides a path for this excess energy to dissipate harmlessly.) The downside of having a diode in the circuit is that the electrical contacts are now polarised and correct polarity of any applied test voltage must be observed otherwise the diode will burn out. This just means that the '+' and '-' signs on the next diagram '''[[must be observed]]''' when applying a 12 Volt DC test voltage. | The electrical circuit diagram is very simple with the two coils just connected in parallel. A diode is also connected across the coils to reduce current surge when the coils are switched off. (Here is the theory: The magnetic energy stored in energised coils can generate a large spark across the operating switch when it is opened and consequently burn the electrical contacts in the switch. A diode provides a path for this excess energy to dissipate harmlessly.) The downside of having a diode in the circuit is that the electrical contacts are now polarised and correct polarity of any applied test voltage must be observed otherwise the diode will burn out. This just means that the '+' and '-' signs on the next diagram '''[[must be observed]]''' when applying a 12 Volt DC test voltage. | ||

Circuit Diagram of Trunk Lid Actuator Pneumatic Solenoid Valves | Circuit Diagram of Trunk Lid Actuator Pneumatic Solenoid Valves | ||

[[File:W220 Trunk Lid Actuator Pneumatic Solenoid Valves 03.JPG|400px|center]] | [[File:W220 Trunk Lid Actuator Pneumatic Solenoid Valves 03.JPG|400px|center]] | ||

Revision as of 08:06, 26 February 2016

Description - Trunk/Boot

TBD

Functions - Trunk/Boot

TBD

Issues - Trunk/Boot

Common issues relating to the trunk/boot lid functions are;

- Hissing Sound on Trunk Opening or Closure

- Broken or Failed Pneumatic Actuators.

- Cracked or broken pneumatic lines.

- Cannot remove the actuator rod to get the locking mechanism out of the trunk

- Leakage of water into the trunk because the power closing assist fails to pull the lid closed completely.

- Cannot open the trunk when the battery is dead.

EMERGENCY OPENING - Trunk/Boot

Trunk Opening with a Dead Battery

A completely dead battery prevents the boot lid from being electrically opened. A jump start is not possible if you cannot access the battery as the W220 does not have accessible jump ports.

If the trunk is locked and the battery is dead try these techniques for opening the trunk lid.

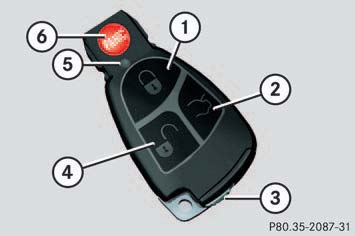

Solution 1: Extract the mechanical key from the SmartKey and use it to open the trunk.

Solution 2: If the mechanical key doesn't work you may have to charge the battery prior to jump starting the car.

- Pull the carpet back from the top under the front passenger side dash.

- Behind the Styrofoam insulation there is an aluminum plate.

- Unscrew the 3-4 bolts to get to the positive terminal.

- Hook up a charger and charge the battery as long as possible.

- After a while you should be able to start the car.

- If the trunk still will not open reset it by removing the 20A yellow fuse from under the rear right passenger seat fuse box.

- Leave it out for about 5 mins.

- Then put it back in and then try to open the Trunk.

- The Trunk should now open.

Trunk Opening Without a Key

To open the trunk if for some reason it cannot be opened using smartkey or mechanical key, you can use this method which will cause only minor damage of the lid covering.

- Detach the licence plate from the trunk lid covering.

- The covering (9) is a big plastic part mounted on the lid. Remove the covering:

- Pre-facelift:

- You will see two screws in the middle of covering (9). Remove them.

- You have to remove covering by force using plastic molding remover tool. Note, that there are 7 bolts (10) that are tightened from the inside to hold the covering (9) in place. You will damage plastic housing for these bolts in the covering. However, it is very common to see these housings already damaged. Furthermore, the covering holds to the lid just fine only using the two central screws.

- Facelift:

- Note, that there are 8 clips (10) and one bolt in the center tightened from the inside that hold the covering (9) in place. You have to drill off the head of center bolt holding the covering. This bolt is not crucial, since the covering holds to the lid just fine using only the clips.

- Pre-facelift:

- After covering is removed you will see three T30 torx bolts (12) holding the trunk lid handle. Unscrew them.

- Push the whole trunk lid handle inside through the hole while pushing the button.

- You will hear the pop noise. Trunk lid is open.

- In case the release rod (14) that connects the trunk lid lock (1) to the trunk lid handle (13) is disconnected, you can use a needled nose pliers to release the rod and open the trunk.

|

|

|

Normal Opening - Trunk/Boot

WARNING: A minimum height clearance of 6 ft. (1.85 m) is required to open the trunk lid fully.

Unlocking and opening the trunk lid using SmartKey

Press and hold trunk lid unlock button (2) on the SmartKey until trunk unlocks and begins to open.

If the trunk lid does not open, it is still locked separately (see below).

Opening the trunk lid from the inside

You can open the trunk from the inside if the vehicle is stationary.

The switch is located on the driver's door.

- (1) Indicator lamp

- (2) Remote trunk lid release switch

Pull remote trunk lid switch (2) until trunk begins to open. The trunk lid opens. The indicator lamp (1) comes on and remains lit until the trunk is closed.

Even with the SmartKey removed from the starter switch or the SmartKey with KEYLESS-GO removed from the vehicle, the remote trunk lid switch can be operated.

If the vehicle was previously centrally locked, the trunk lid will lock automatically when closed. The turn signals will flash three times to confirm locking.

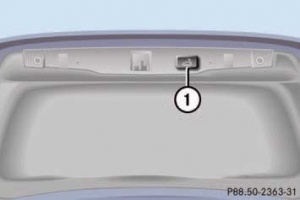

Opening the trunk lid using emergency release

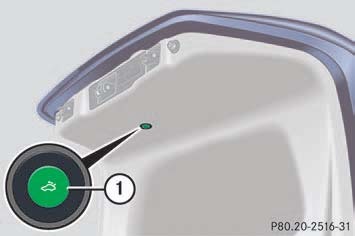

Some W220 S-Class vehicles have an emergency release button so that you do not get trapped inside.

The emergency release button is located on the inside of the trunk lid. Briefly press emergency release button (1). The trunk unlocks and the trunk lid opens. The emergency release button unlocks and opens the trunk while the vehicle is standing or driving. The emergency release button does not open the trunk lid if the vehicle battery is discharged or disconnected.

Illumination of the emergency release button:

- The button will flash for 30 minutes after opening the trunk.

- The button will flash for 60 minutes after closing the trunk.

If the emergency release button is pressed and the vehicle was centrally locked, the exterior lamps will flash and the alarm will sound as the trunk lid opens.

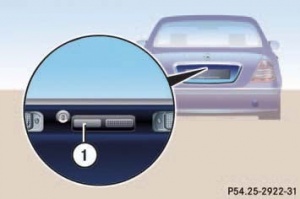

Opening the trunk lid from the outside

|

|

The trunk lid open button is located in the rear license plate recess. Press the outer left-hand side of trunk lid button (1). The trunk lid opens.

Vehicles with KEYLESS-GO: If the vehicle was previously centrally locked, the trunk lid will lock automatically after closing it.

Normal Closing - Trunk/Boot

WARNING: Do not place the SmartKey in the open trunk. You may lock yourself out.

Vehicles with KEYLESS-GO: To prevent a possible inadvertent lockout, the trunk lid will open automatically if a SmartKey with KEYLESS-GO is recognized inside the vehicle or in the trunk.

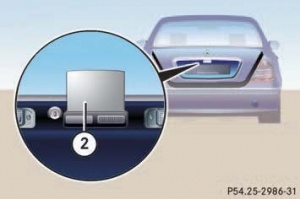

Closing the trunk lid using handle

Lower trunk lid by pulling firmly on handle (1).

|

|

In addition to handle (1), facelift vehicles can be closed using the extending handle (Retractable Trunk Grip (RTG)) built into the trunk lid handle (2). Push the trunk lid down gently at the extending handle (2) until it engages into the lock. The extending handle (2) is retracted after a few seconds. The power closing assist automatically ensures that the lid is pulled closed completely.

Remote Closing - Trunk/Boot

On vehicles with option code 881 - REMOTE TRUNK LOCKING the trunk lid can be closed by a press of button.

If the trunk lid comes into contact with an object while closing (e.g. luggage that has been piled too high) in the upper motion sequence, the closing procedure is stopped and the trunk reopens slightly.

The trunk lid opening height can be limited when transporting goods on a roof rack (e.g. presence of an MB sport luggage container).

When activated, the trunk lid opens to approximately the height of the roof edge.

You can activate the limiting opening height of trunk lid using the control system.

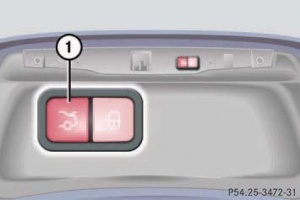

The closing procedure can be stopped at any time by pressing the trunk lid closing switch (on the driver's door), the trunk lid closing switch (1), or the "trunk lid unlock" button on the SmartKey.

Closing from the outside

Press trunk lid closing switch (1) briefly. The trunk lid closes.

On vehicles with trunk lid closing system and KEYLESS-GO, you can close the trunk lid and lock the vehicle simultaneously using the second button on the switch.

|

|

|

Make sure you have the SmartKey with KEYLESS-GO with you. Press trunk lid closing switch (1) (in the second picture) briefly. The vehicle is locked and the trunk lid closes automatically. The turn signals flash three times to confirm locking.

Closing from the inside

The trunk lid can be closed from the inside using the opening switch if the vehicle is stationary.

Press remote trunk lid switch (2) until the indicator lamp (1) goes out and trunk lid is closed. To interrupt the closing procedure release remote trunk lid switch (2).

Restricting Access with Additional Locking Mechanism - Trunk/Boot

Vehicles equipped with option code 884 - TRUNK LID ADDITIONAL LOCKING MECHANISM (HZS) have a function permitting the separate locking of the trunk using the mechanical key. If present, this feature can permit you to deny any unauthorized person access to the trunk by locking the trunk separately and leaving the SmartKey less the mechanical key with the vehicle.

To verify the presence of this feature, use the mechanical key to lock the trunk and then attempt to open the trunk by pressing the trunk lid button after the vehicle has been centrally unlocked with the SmartKey.

The lock is located next to the recessed handle.

Close the trunk lid. Pull the mechanical key out of the SmartKey. Insert the mechanical key into the trunk lid lock. Turn the mechanical key clockwise to vertical position. The trunk remains locked even when the vehicle is centrally unlocked. You can only cancel the separate trunk locking mode by means of the mechanical key.

Trunk lid

|

|

|

|

Trunk lid covering

There are differences between pre-facelift and facelift vehicles in how trunk lid covering attached to the trunk lid.

Pre-facelift

Pre-facelift vehicles (To Date: 01/09/2002) have lid covering A2207500081 which is attached to the lid with two screws in center tightened from outside and 7 screws tightened from inside.

|

|

Facelift

Facelift vehicles (From Date: 30/09/2002) have lid covering A2207500281 which is attached to the lid with one bolt in center tightened from inside and 8 retaining clips. The covering has also different trunk lid handle opening modified for retractable trunk lid grip.

|

|

|

The U.S. version A2207500381 has smaller distance between licence plate mounting holes.

|

|

Locking Mechanism Actuator - Trunk/Boot

Functions - Trunk Locking Mechanism Actuator

The W220 trunk lid actuator is pneumatically controlled and can have some or all of the following functions:

- Auto opening (all vehicles)

- Auto or self closing (vehicles with option code 881)

- Extension and retraction of trunk lid handle (facelift vehicles)

The positive and negative pressures required for the pneumatic control of the Trunk/Boot Lid functions are generated by the Pneumatic System Equipment (PSE) Pump.

Part Numbers - Trunk Locking Mechanism Actuator

- Whole Assembly - Trunk Locking Mechanism Actuator 220 750 06 84, 2207500684.

- Vacuum Servo Only (Black) - Trunk Locking Mechanism Actuator 220 750 01 85, 2207500185.

- Air Servo Only (White) - Trunk Locking Mechanism Actuator 220 800 05 75, 2208000575.

DIY Procedures - Trunk/Boot

DIY 1 - Removing Trunk Lid Lining

|

|

|

|

|

|

|

|

|

DIY 2 - Removing Trunk Lining

DIY 3 - Welding trunk lid covering holes

Trunk lid has 7 (pre-facelift) or 8 (facelift) holes which are used to attach the trunk covering (9) to the trunk lid. It is common to see these holes being a source for moisture and rust inside the trunk lid. As an anti-rust measure these holes can be closed by welding. The trunk covering still remains attached to the trunk lid by two central screws (pre-facelift) or one central screw (facelift), although double sided type is recommended to prevent vibration of the covering.

|

|

DIY 4 - Repair of Broken Trunk Lid Actuator 01

With thanks to BenzWorld member 'subscriber' for posting an excellent description of his repair of a broken locking mechanism pneumatic actuator.

Note the broken plastic tabs on the perimeter of the actuator.

See http://www.benzworld.org/forums/w220-s-class/2532833-repair-part-220-750-0684-trunk.html

DIY 5 - Repair of Broken Trunk Lid Actuator 02

See WIS 88.52 Retractable Trunk Lid Grip (RTG) for a DIY repair of a broken actuator.

DIY 6 - Repair of Trunk Lid Actuator Pneumatic Solenoid Valves

In the Actuator there is a double solenoid valve which distributes the pneumatic pressure to the relevant actuator depending on the required result.

The exact description of which coil does what has yet to be determined and wasn't necessary for a thorough clean and bench test. It is something like the following: (Reference: HECK function on Pneumatic System Equipment (PSE) Pump.

- When the Boot/Trunk Lid is closed manually to the first position as identified by a loud click, the PSE HECK port provides +ve pressure (27KPa or 4psi) to the Boot/Trunk Lid Solenoid Valve Assembly and hence to the Large White Actuator which pulls the boot closed tightly, then the PSE HECK port changes to –ve pressure (19”Hg vacuum), which retracts the Handle (RTG), then returns the line to atmospheric pressure.

- When the Boot/Trunk Lid is commanded to open either by remote control on the key fob, by pressing the Boot/Trunk Lid button, or by pulling the internal Boot/Trunk Lid release button on the driver's door, the PSE HECK port provides +ve pressure (27KPa or 4psi) to the Boot/Trunk Lid Solenoid Valve Assembly and hence to the Small Black Actuator or "Hockey Puck" which opens the locking latch, thus releasing the lid which fully opens. +ve Pressure is also applied to the RTG Handle, which extends the Handle. After all this is finished the pneumatic line returns to atmospheric pressure.

DIY 7 - Clean and Regrease Trunk Lid Actuator Pneumatic Solenoid Valves

Once the Boot/Trunk Lid Pneumatic Actuator is removed from the vehicle it can be dismantled on the work bench. See WIS 88.52 Retractable Trunk Lid Grip (RTG) for the removal method.

- Press in the two small plastic tabs and the Pneumatic Solenoid Valve Assembly can be with drawn.

- Remove the top front cover over the electrical connector.

- Then press in two small plastic tabs and remove the top rear cover.

Photo of disassembled Pneumatic Solenoid Valve Assembly

Closeup of coils and seals.

- Before reassembly check the electrical pneumatic solenoid valves.

- Reassemble in the reverse order but apply silicon dielectric or vacuum grease to the pneumatic seals before assembly.

DIY 8 - Check Electrical Trunk Lid Pneumatic Solenoid Valves

The electrical circuit diagram is very simple with the two coils just connected in parallel. A diode is also connected across the coils to reduce current surge when the coils are switched off. (Here is the theory: The magnetic energy stored in energised coils can generate a large spark across the operating switch when it is opened and consequently burn the electrical contacts in the switch. A diode provides a path for this excess energy to dissipate harmlessly.) The downside of having a diode in the circuit is that the electrical contacts are now polarised and correct polarity of any applied test voltage must be observed otherwise the diode will burn out. This just means that the '+' and '-' signs on the next diagram must be observed when applying a 12 Volt DC test voltage.

Circuit Diagram of Trunk Lid Actuator Pneumatic Solenoid Valves