Airmatic: Difference between revisions

Ricebubbles (talk | contribs) |

Ricebubbles (talk | contribs) (→Air Filter/Cleaner: Added Air Filter/Cleaner Protective Boot) |

||

| Line 408: | Line 408: | ||

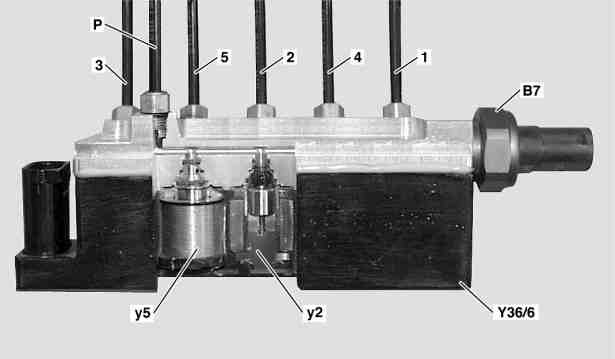

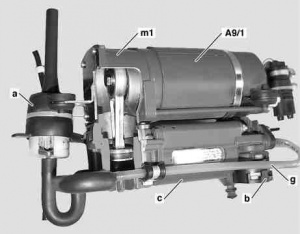

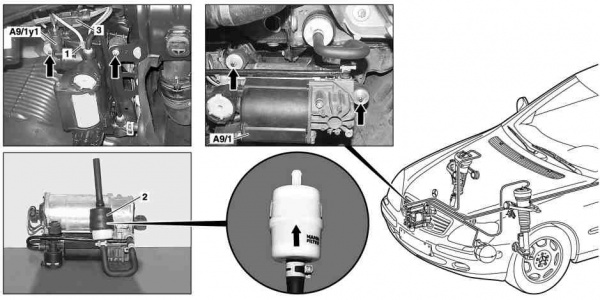

The OEM part numbers are shown on this 2004 AIRmatic Compressor Unit. | The OEM part numbers are shown on this 2004 AIRmatic Compressor Unit. | ||

[[File:W220 2004 AIRmatic Compressor OEM Part Numbers.JPG|600px|center]] | [[File:W220 2004 AIRmatic Compressor OEM Part Numbers.JPG|600px|center]] | ||

===== Air Filter/Cleaner ===== | ===== Air Filter/Cleaner - AIRmatic ===== | ||

The Air Filter/Cleaner part number is: A2203200069. | The AIRmatic Compressor Air Filter/Cleaner part number is: A220 320 00 69 or A2203200069. | ||

Some catalogues list it as "Air Filter, compressor intake." | Some catalogues list it as "Air Filter, compressor intake." | ||

[[File:Airmatic Air Filter 2203200069.JPG| | [[File:Airmatic Air Filter 2203200069.JPG|400px|center|]] | ||

A new | A new AIRmatic air filter/cleaner costs around EUR 10, and it should not take more than 20 minutes to replace. For replacement instruction see compressor replacement instruction below. | ||

For replacement instruction see compressor replacement instruction below. | |||

===== Air Filter/Cleaner Protective Boot - AIRmatic ===== | |||

The Air Filter/Cleaner is protected with a Protective Boot. ('''Note''': The arrow on the Air Filter/Cleaner shows the 'UP' direction and not the direction of air flow which is both ways.) | |||

[[File:W220 AIRmatic Air Filter and Protective Boot.JPG|400px|center]] | |||

The Air Filter/Cleaner Protective Boot part number is: A 220 328 02 79 or A2203280279. | |||

[[File:W220 AIRmatic Air Filter Protective Boot Showing Part Number.JPG|400px|center]] | |||

=== Level Control Valve Unit (Y36/6) - AIRmatic Compressor Unit === | === Level Control Valve Unit (Y36/6) - AIRmatic Compressor Unit === | ||

Revision as of 10:27, 14 November 2016

Introduction - AIRmatic

All W220 vehicles come with Airmatic pneumatic suspension system, unless vehicle has option code 487 in which case the vehicle is equipped with Active Body Control (ABC) hydraulic suspension system with additional computer control. ABC system provides greater roll control and eliminates any "nosedive" even with heavy braking (not that there is much of either with Airmatic). Both suspension systems are responsible for the superb ride and handling of the W220 and being complex systems will require maintenance.

Airmatic systems on earlier cars tended to fail more often than on the '03 and later - the '04s and on are less problematic. However, there is no such thing a "bulletproof" pneumatic suspension system. Seals and pumps will wear, and struts will have to be replaced. You'd have to do the same thing with standard shocks, too - but Airmatic will be more expensive. The best protection is to become familiar with the early signs of Airmatic problems, and fix them right away. Letting them go runs the cost up.

They are not especially problematic, but like any complex system, they break - and any luxury car is expensive to repair. Keep in mind that if the garage you use does not have STAR Diagnostics and can not interpret the values both in sensor voltage and other tests, then don't waste your time and money. Find someone who can. DIY is possible but preferably requires use of STAR Diagnostics with some prior experience and always lots of patience.

One common failure point which was initially subject to inspection and free replacement, was the high-pressure line from the pump to the valve body.

Another common weakness in the pre '03-ish W220's compared to those from a few years later, is the seals at the tops of the front suspension struts. The older design can leak air over time. The newer models and ones with new replacement parts do not leak. Cars that were under warranty could have these seals replaced with that coverage.

Other issues are shown below.

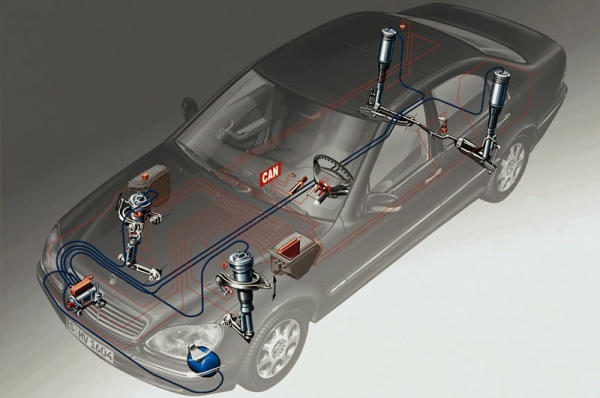

Description - AIRmatic

The W220 Airmatic system is a fully supporting air suspension system which provides both static and dynamic support by means of four air bellows or struts located at the wheels. Each strut has an air bag and a dampener built-in the one unit. The struts get air from an air compressor located behind the front bumper close to the front wheel well. On the opposite side is the central reservoir which supplies pressure via pressure lines and a valve unit. The valve unit is connected to a computer which monitors the air pressure, the vehicle weight, the vehicle height requirement and vehicle stance (angle) and then sets the ride height accordingly.

Identification of Front Struts - AIRmatic

To identify early and later types of W220 front struts inspect the top of the front strut where the air pipe connects.

This is the original oldest style front strut (used in '00 and early '01) which did not have the epoxy.

Front struts on W220s up to about 2004 did have epoxy installed at the factory. Also many of the older style front strut have now been modified with mastic or epoxy added. Note: The epoxy is not the seal for the upper strut. It is a vibration damper to help the narrow neck of the brass valve at the top of the strut avoid cracking and leaking due to vibration. If you have a leak in this older style front strut there is a kit you can buy to fix the leak. (See below.) Scraping out the old black epoxy and filling it back in will not fix this. The part that leaks is a half metal and rubber cap under the black epoxy and is secured with a metal lock ring.

The next figure shows the newer style front strut with mastic. The newer seals have rubber mastic compound poured in the center to seal the circumference of the upper metal cap on the upper part of the front strut and to keep the brass fitting from breaking off.

Features - AIRmatic

- Level control both manual and speed sensitive.

- Electronic level control which maintains a constant even level at the front and rear axles according to the driving and vehicle load conditions.

- When the vehicle is stationary the level is readjusted if there is a difference of more than +/- 10mm after a door or the trunk lid is opened.

- While driving the level is readjusted if there is a difference of more than +/- 20mm. The level is adjusted to +/- 10 mm every 15 minutes.

- Active Damping System (ADS) which changes the damping forces according to the road conditions and the driver's driving style. The road conditions are determined by vertical acceleration sensors in the body of the vehicle. The horizontal acceleration is determined by measuring the vehicle speed and turn angle.

Advantages - AIRmatic

Higher level of driving safety and ride comfort due to:

- Adapting damping to road conditions and driving style.

- Low location of centre of gravity as vehicle lowers above 70KPH.

- Low aerodynamic drag and fuel consumption as vehicle lowers above 70KPH.

- Less tendency for vehicle to lift at speed.

Individual adaptation due to:

- Raising vehicle level for poor road surfaces and when negotiating driveways.

- Two possible damping levels for comfort or sport driving styles in vehicles produced up to 08/99.

- Three possible damping levels for comfort, sport or extreme sport driving styles in vehicles produced after 09/99.

Driver information due to:

- Vehicle level displayed by indicator lamps and switches.

- Warning messages in multi-function display if vehicle is too low.

Function - AIRmatic

The functions of the AIRmatic with Adaptive Damping System (ADS) control module are divided as follows:

- Signal conditioning

- Function logic component

- Safety circuit

Signal conditioning

The following input signals are processed by the function logic component and used for calculations or to provide information:

- Calculation of body vertical acceleration

- Signal from body acceleration sensors

- Calculation of vehicle speed

- Wheel speed signal

- Speed status signal

- Calculation of longitudinal and lateral acceleration

- Wheel speed signal

- Signal from steering angle sensor

- Calculation of compressor control

- Outside temperature, outside air pressure signal

- Reservoir pressure signal

- Vehicle speed signal

- Vehicle level signal

- Duty cycle

- Calculation for valve control

- Level signal from left front axle, right front axle

- Rear axle level signal

- Calculation for control of main reservoir charge valve

- Level signal from left front axle, right front axle

- Rear axle

- Pressure signal

- Calculation of vehicle level

- Signal from level sensors

- Information signals (control)

- Signal from stop lamp switch

- Signal from comfort and sport switch

- Signal from level control switch

- Signal from door contact switch, trunk, remote control

Function logic component

The conditioned input signals are processed in the logic component and converted into output signals.

- Signal from body acceleration sensors (B24/3, B24/8, B24/9):

- The vertical acceleration of the vehicle is calculated using the signals from the body acceleration sensors.

- Front wheel speed signal, left and right:

- Using the wheel speed signal, the ESP control module calculates

- Vehicle speed

- Longitudinal acceleration

- Vehicle status. A distinction is made between a moving and a stationary vehicle. Incorrect wheel speed signals are also detected.

- Steering angle sensor signal (N49):

- The lateral acceleration of the vehicle is calculated using the steering angle sensor signal and the wheel speed signal.

- Signal from level sensors (B22/8, B22/9, B22/3):

- Both front axle level sensors each supply 2 signals. The sensors detect and transfer the distance between the wheel center and the body at both the left and right-hand side of the vehicle.

- The rear axle level sensor supplies 2 signals. The sensor detects and transfers the distance between the wheel center and the body (average calculated from left and right wheel).

- Brake lamp switch signal (S9/1):

- When the driver presses the brake pedal, a signal is received by the ADS logic component and the damping at all wheels is set to "hard". The pitch motion of the vehicle when braking can therefore be reduced.

- Comfort and sport switch signal (N72/1s3):

- The comfort and sport switch signal informs the system about the selection made by the driver between one comfort-oriented and 2 sporty damping maps. The "comfort" setting maintains the damping within the comfortable range as far as the driving style and road conditions will allow. The "Sport 1" setting makes the damping somewhat "harder". The "Sport 2" setting immediately sets the damping force to "hard". The driver's preferred settings are stored until changed by the driver (even with Ignition OFF).

- Signal from level adjustment switch (N72/1s2):

- The control module uses the signals from the level adjustment switch to determine the driver's preferences for the vehicle level:

- Normal level

- Raised level

- The control module uses the signals from the level adjustment switch to determine the driver's preferences for the vehicle level:

- ADS II

- The control module uses the vertical body acceleration, longitudinal and lateral acceleration of the vehicle and the ground speed to determine the optimum level of damping. 4 different damping forces can be set at each wheel by controlling the damping valves located at each wheel. Phased in as of 09/00, the damping is set to the Sport 1 damping level if the vehicle speed is >160 km/h.

- Level control and adjustment

- The control module uses the setting of the level adjustment switch selected by the driver and the ground speed of the vehicle to control the appropriate level control valves and to set the correct vehicle level according to the vehicle load.

- The AIRmatic system is equipped with a pressure reservoir to keep the level control time as short as possible (e.g. after loading). The reservoir pressure is used only when required in order to prevent filling the reservoir too often. This happens, for example if the vehicle level falls below a critical level when loading the vehicle or if the driver has set the vehicle level to "raised level". Pressure from the reservoir is also used when the vehicle is stationary to minimize noise. With normal control when the vehicle is moving, the spring struts are supplied directly by the air compressor.

- Main reservoir pressure control

- The main control parameters are the pressure in the main reservoir, the outside air pressure and the vehicle speed.

- Compressor control

- The compressor is controlled via a relay. Since the compressor is not designed for continuous operation, the absolute running time and cooling phase are monitored to avoid overloading the compressor.

- Wake-up function

A parked vehicle is "woken up" before the engine is started. That is to say, the AIRmatic with ADS control module receives signals from the door contact switches, the trunk switch and infrared remote control indicating that the driver may soon start the engine and drive the vehicle. The current vehicle level is checked immediately and corrected if required. The vehicle level at the front axle is considered to be critical, for instance, if the full wheel angle can no longer be guaranteed. In this case a message appears on the multifunction display in the instrument cluster to warn the driver: "Stop car too low". If the control module is woken (for example by opening one of the doors), there follows a period of spare time before the driver actually starts the engine during which the vehicle level is corrected. This reduces the waiting time required to correct the vehicle level and the vehicle is ready for driving more promptly. Pressure in the main reservoir is used to raise the stationary vehicle. The compressor is only used if the pressure reservoir is empty. It must be ensured that the battery voltage is sufficient to then start the engine.

- Locking function

If the control module detects that all wheels are unloaded when the vehicle is stationary, the valves of the sprint struts are closed. The vehicle therefore remains at the current level. This is essential, for example, when changing a wheel or during repair work (lifting platform).

Safety circuit

The AIRmatic with ADS control module monitors all the important components of the system after they are switched on and during operation. The safety circuit detects faulty signals from sensors, faults in the control module and in the electric line system. If a fault is detected, the system is switched off and a message is displayed on the multifunction display in the instrument cluster to warn the driver. The damper valves for ADS are no longer controlled and remain set to the "hard" damping level (driving safety level). In addition, a fault code is stored in the control module. The level control is partially switched off depending on the fault that occurred. The system always strives to maintain the selected vehicle level. Moreover, the safety circuit continuously monitors the battery voltage. If the voltage falls below 10.5 V or exceeds 17.5 V, the system is switched off until the voltage returns to the specified range.

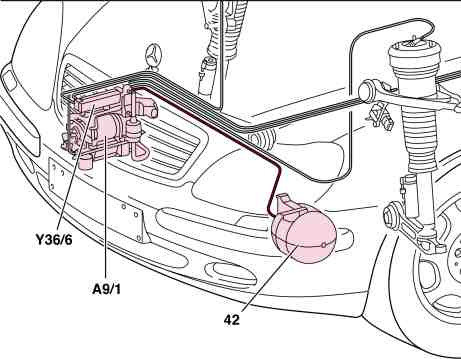

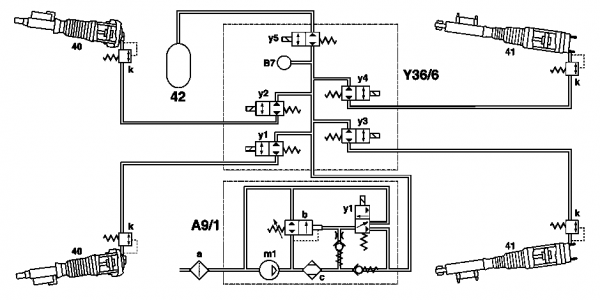

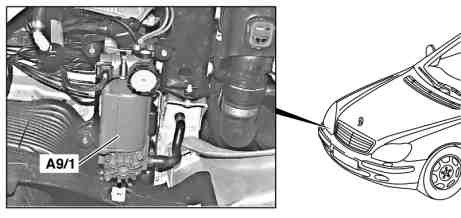

Pressure Supply Function - AIRmatic

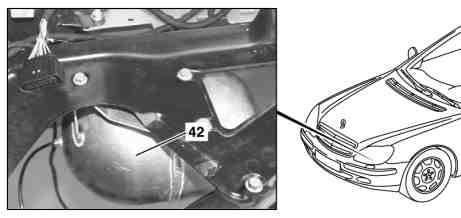

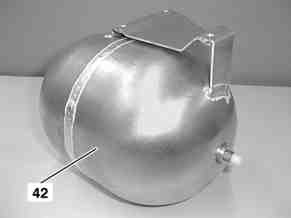

- 42 - AIRmatic Central Reservoir

- A9/1 - AIRmatic Compressor Unit

- Y36/6 - Level Control Valve Unit

In normal driving mode, AIRmatic works with a pressure of between 6 and 10 bar (600 and 1,000 KPa or 87 and 145 psi) depending on the load. An electrical compressor is used to supply pressure. This is installed in the AIRmatic Compressor Unit (A9/1).

In addition the system has an AIRmatic Central Reservoir (42) which stores the compressed-air. The AIRmatic Central Reservoir (42)pressure is between 13 and 16 bar (1,300 and 1,600 KPa or 189 and 232 psi) (at sea level).

The AIRmatic system is either supplied with pressure via the AIRmatic Central Reservoir (42) or via the AIRmatic Compressor Unit (A9/1).

Level Control Function - AIRmatic

The AIRmatic at the front and rear axle is a fully supporting suspension system. It keeps the vehicle level constant when the engine is running irrespective of the load. At the same time air from the air compressor is delivered to the spring struts via the valve unit until the vehicle level has been adjusted. The vehicle level at the front axle is recorded by two level sensors at the rear axle and conveyed to the AIRmatic with ADS control module. The level at the individual spring struts is controlled by four level valves in the valve unit and a pressure relief valve on the AIRmatic compressor unit.

An AIRmatic central reservoir for compressed air also enables the vehicle level to be controlled when the engine is not running. In addition the adjustment of the vehicle level is decoupled from the air compressor.

Shut-off position function

If the unloading of all the wheels when the vehicle is stationary is recognized by the control module, the spring strut valves are closed. The vehicle therefore remains at the current level. This is required when changing a wheel or for repair work (hoist) for example.

Normal function (engine running)

When the vehicle is stationary the level is readjusted if there is a difference of more than +/- 10 mm after a door or the trunk lid is opened.

While driving the level is readjusted if there is a difference of more than +/- 20 mm. The level is adjusted to +/- 10 mm every 15 minutes.

Depending on the situation, pressure can be generated by the compressor or the pressure supply of the AIRmatic central reservoir can be used to raise the vehicle. When the vehicle is stationary the pressure from the reservoir is used for noise reasons. Pressure can also be supplied from the compressor and AIRmatic central reservoir at the same time when there is a particularly high pressure demand.

The lowering of the vehicle level is recognized by the control module from the level sensors when loading the vehicle. By actuating solenoid valves air is delivered to the spring struts of the particular front wheel or rear axle until the vehicle has reached its specified value. In addition the pressure relief valve is opened to actuate the respective wheel valve when unloading the vehicle.

Wake-up function (operating period approx. 1 minute)

The AIRmatic with ADS control module is "woken up" using the remote control, door contact switches or trunk illumination switch in order to check the current vehicle level for critical conditions (level too low) and if necessary to raise the vehicle or lower it when unloading. If the vehicle level is lowered by more than 30 mm, it is raised to the normal level by the reservoir (only with a reservoir pressure > 11 bar). At a vehicle level of < -65 mm and even at a reservoir pressure of <11 bar it is raised out of the "critical range" by the compressor to -63 mm (condition: battery voltage > 12.4 V).

If the vehicle level is raised by more than 10 mm when unloading, it is lowered to the normal level by relieving the pressure.

The vehicle cannot be raised by the level control switch.

Function in vehicle condition "Ignition ON"

The same function as for the wake-up function, but without time limit.

Run-on function (operating period approx. 1 minute)

After "ignition OFF" the control module performs changes in the level in order to be able to readjust the vehicle level (raise or lower) during any loading or unloading operations. (The same function as for the wake-up function).

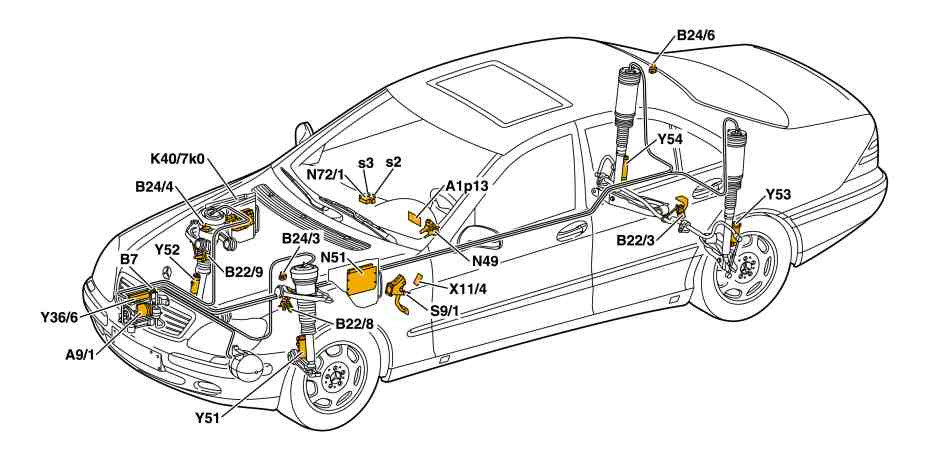

Components - AIRmatic

Location of electrical/electronic components - AIRmatic:

- A9/1 - AIRmatic compressor unit

- A1p13 - Multifunction display

- B7 - AIRmatic pressure sensor

- B22/3 - Rear axle level sensor

- B22/8 - Left front level sensor

- B22/9 - Right front level sensor

- B24/3 - Left front body acceleration sensor

- B24/4 - Right front body acceleration sensor

- B24/6 - Right rear body acceleration sensor

- K40/7 - Right front fuse and relay module

- kO - AIRmatic compressor relay

- N49 - Steering angle sensor

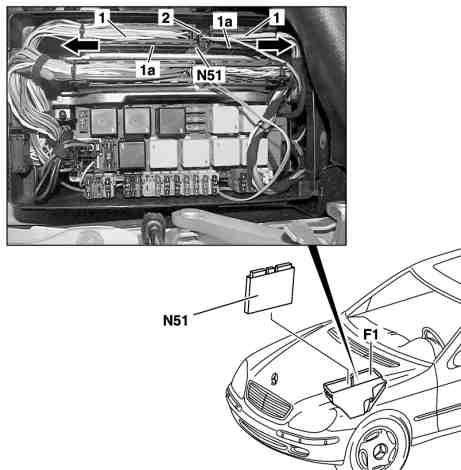

- N51 - AIRmatic with ADS control module

- N72/1s2 - Level control switch

- N72/1s3 - Comfort and sport switch

- S9/1 - Stop lamp switch

- X11/4 - Data link connector

- Y36/6 - Level control valve unit

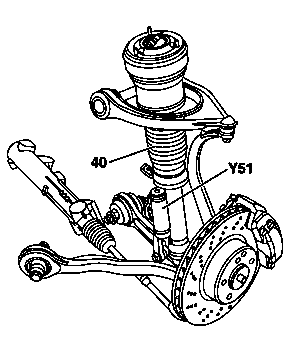

- Y51 - Left front axle damping valve unit

- Y52 - Right front axle damping valve unit

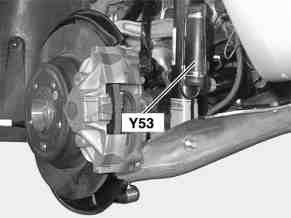

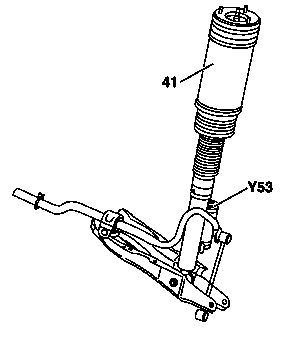

- Y53 - Left rear axle damping valve unit

- Y54 - Right rear axle damping valve unit

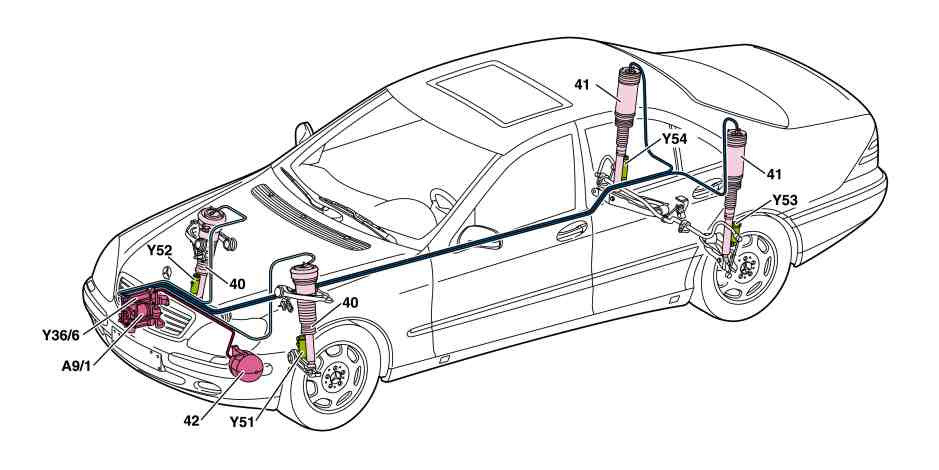

Location of pneumatic/hydraulic components - AIRmatic:

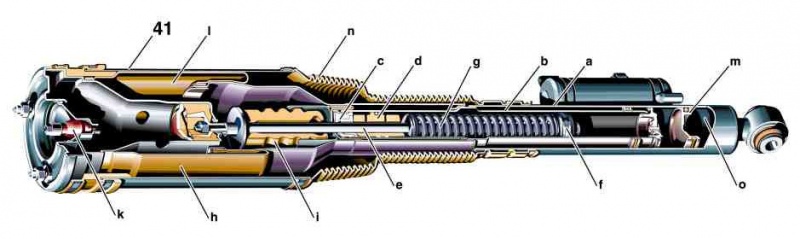

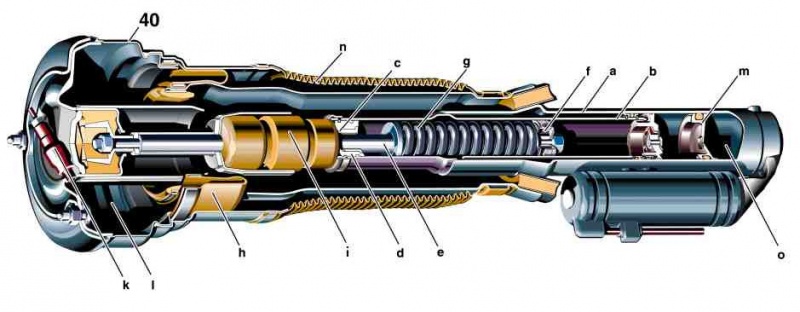

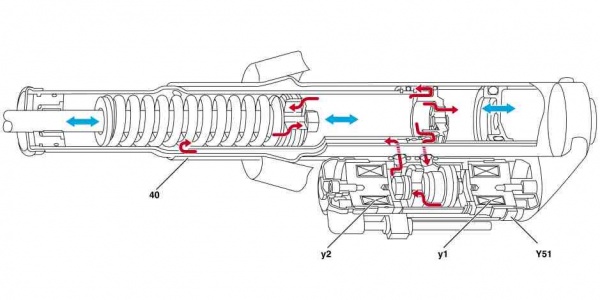

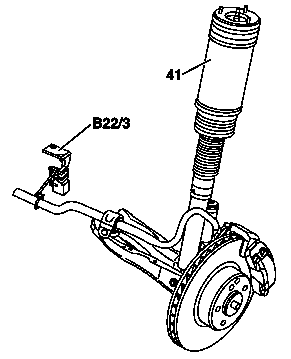

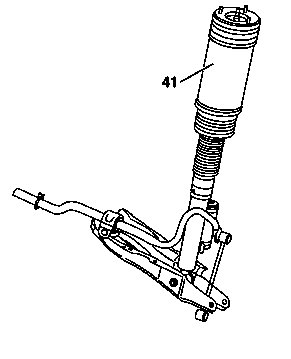

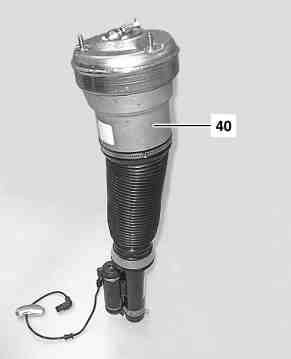

- 40 - Front spring strut

- 41 - Rear spring strut

- 42 - AIRmatic central reservoir

- A9/1 - AIRmatic compressor unit

- Y36/6 - Level control valve unit

- Y51 - Left front axle damping valve unit

- Y52 - Right front axle damping valve unit

- Y53 - Left rear axle damping valve unit

- Y54 - Right rear axle damping valve unit

AIRmatic Compressor Unit (A9/1)

The electric compressor generates the pressure required to lift the vehicle. The pressure relief valve integrated in the AIRmatic Compressor Unit (A9/1) is used to lower the vehicle.

|

|

|

|

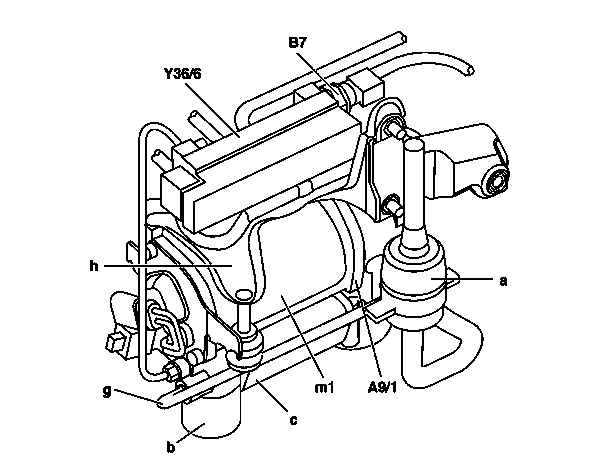

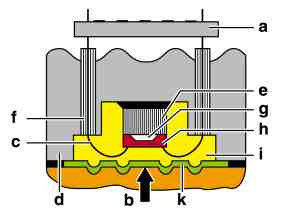

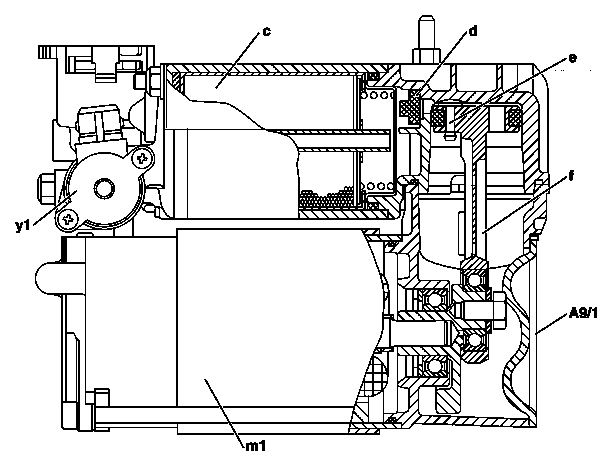

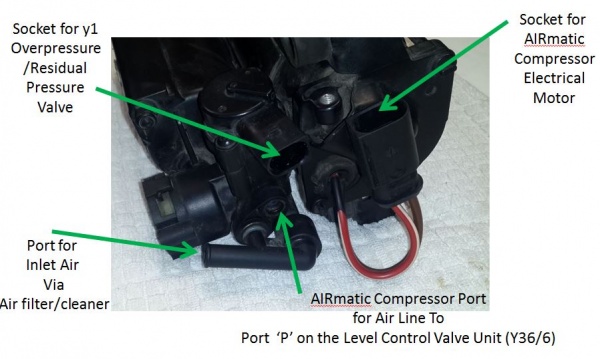

Design - AIRmatic Compressor Unit

|

The main part of the AIRmatic Compressor Unit (A9/1) is the compressor motor (m1). The other parts are the pressure relief valve, overpressure/residual pressure valve (b) and the air drier (c).

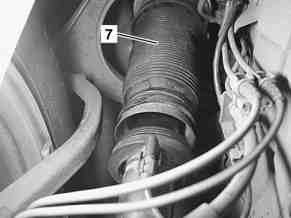

The air filter/cleaner (a) is located outside the compressor unit. It is connected to the unit by a hose. The air released when the vehicle is lowered is returned to the air filter/cleaner via the line (g) where it is then guided back out through the filter.

The compressor unit is mounted to a mounting plate (h).

The AIRmatic Level Control Valve Unit (Y36/6) is fixed at the top of the same mounting plate as the compressor unit and is connected to the compressor by a pressure line.

The valve unit is attached to the AIRmatic pressure sensor (B7).

Function - AIRmatic Compressor Unit

|

|

The air compressor is driven by the compressor motor (m1). The air to be compressed is sucked out of the vehicle longitudinal member through an air filter/cleaner and into the chamber underneath the piston. With the downward movement of the piston, the air passes through the inlet valve (e) in the piston crown into the clearance volume. With the upward movement of the piston, the inlet valve closes and the air is compressed. The compressed air is forced on via the outlet valve (d) into the air drier (c).

The silicate filling in the drier removes moisture from the air. From the air drier the dehumidified and compressed air then passes from the air drier into the central reservoir or directly to the suspension struts as required.

The pressure relief valve installed in the compressor unit (y1) is required for discharging air when lowering the vehicle. The discharged air is conducted through the air filter/cleaner back into the atmosphere. This also cleans the air filter/cleaner.

The air drier is maintenance free. The moisture is delivered back into the air when reducing the pressure.

Air Filter/Cleaner - AIRmatic

It is difficult to get reliable information about the scheduled maintenance interval on the AIRmatic air filter/cleaner. W220 community recommends to replace the air filter/cleaner from time to time to prevent damage to the AIRmatic compressor. The filter can fill up with debris and salt which may block the air filter/cleaner.

Part Numbers - AIRmatic Compressor Unit

AIRmatic Compressor Unit

The OEM part numbers are shown on this 2004 AIRmatic Compressor Unit.

Air Filter/Cleaner - AIRmatic

The AIRmatic Compressor Air Filter/Cleaner part number is: A220 320 00 69 or A2203200069.

Some catalogues list it as "Air Filter, compressor intake."

A new AIRmatic air filter/cleaner costs around EUR 10, and it should not take more than 20 minutes to replace. For replacement instruction see compressor replacement instruction below.

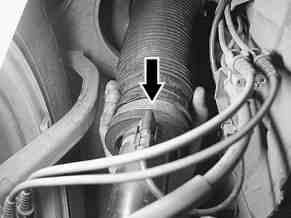

Air Filter/Cleaner Protective Boot - AIRmatic

The Air Filter/Cleaner is protected with a Protective Boot. (Note: The arrow on the Air Filter/Cleaner shows the 'UP' direction and not the direction of air flow which is both ways.)

The Air Filter/Cleaner Protective Boot part number is: A 220 328 02 79 or A2203280279.

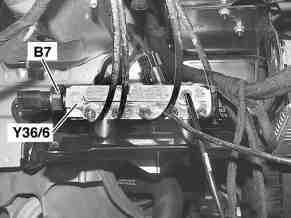

Level Control Valve Unit (Y36/6) - AIRmatic Compressor Unit

Located on the AIRmatic Compressor Unit in the right front fender, the Level Control Valve Unit (Y36/6) is the central control unit for the level control, level adjustment and suspension. It supplies the AIRmatic front and rear spring struts (40, 41) and the AIRmatic Central Reservoir (42) with compressed-air.

|

|

|

See also section "Air Line Colour Codes - Level Control Valve Unit (Y36/6)" below [1].

Design - AIRmatic Level Control Valve Unit (Y36/6)

The AIRmatic Level Control Valve Unit (Y36/6) is attached to the same retaining plate as the AIRmatic Compressor Unit (A9/1). It has a solenoid valve for each wheel (y1, y2, y3 and y4) for raising or lowering the vehicle. The AIRmatic central reservoir charge (y5) is also installed in the valve unit. The AIRmatic pressure sensor (B7) is located on the end face of the valve unit.

See also section "Air Line Colour Codes - Level Control Valve Unit (Y36/6)" below [2].

Function - AIRmatic Level Control Valve Unit

For reasons of safety only one valve is ever actuated at the same time. If an axle is too low, cycling takes place between the left and right level valve.

Raising the vehicle

The front left, front right, rear left and rear right level valves (y1, y2, y3, y4) are opened as required and the compressed-air stored in the central reservoir or generated by the air compressor motor flows from the level control valve unit (Y36/6) to the individual spring struts. As soon as the required vehicle level is reached at a front wheel, the respective level valve (y1 or y2) closes, the other valve still remains open until the same vehicle level has also been adjusted at the other wheel. At the rear axle both level control valves (y3 and y4) close when the vehicle level averaged between the right and left wheel corresponds to the specified level set by the control module.

Lowering the vehicle

All the wheel level control valves (y1, y2, y3 and y4) are open in the level control valve unit (Y36/6). In addition the AIRmatic pressure release valve (y1) in the AIRmatic compressor unit (A9/1) is open and the compressed-air is reduced via this valve. At the same time the level valves of the individual wheels remain open until the desired vehicle level is reached at each front wheel and at the rear axle.

Part Number - AIRmatic Level Control Valve Unit

The OEM part number is A220 320 02 58 or 2203200258.

AIRmatic Pressure Sensor (B7)

The AIRmatic Pressure Sensor (B7) is located in the right front fender on the AIRmatic Level Control Valve Unit. It measures the system pressure and is used to carry out plausibility checks.

|

|

Function - AIRmatic Pressure Sensor (B7)

A sensor element compares the fluid pressure (b) to be measured with a reference pressure (g) in the sensor. The pressure (b) is transmitted to the actual sensor element (h) by means of a metal protective diaphragm (k) and a silicone oil layer (i).

An electronics module (a) which supplies the pressure signal in the form of an analog voltage to the control module, is located on the metal housing (d).

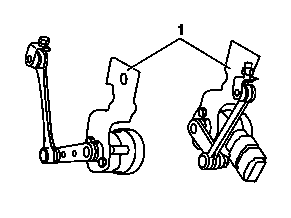

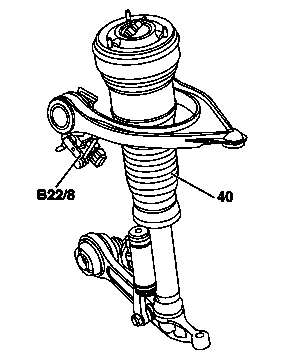

Level Sensor (B22/3, B22/8, B22/9)

- B22/3 - Rear axle level sensor

- B22/8 - Left front level sensor

- B22/9 - Right front level sensor

|

|

Detecting the vehicle level at the front axle and rear axle and supplying the values to the AIRmatic with ADS control module.

Design: 2 Hall sensors in a single housing (redundant design).

Detects vehicle level using link rod from upper transverse control arm at left and right front axle. A sensor at the rear axle monitors the movement of the torsion bar and determines the average vehicle level. Sensor failure is detected by comparing the redundant signals of each sensor.

AIRmatic Central Reservoir (42)

Metal compressed air reservoir. Stores compressed air for level control. Used for decoupling between compressor and level control.

|

Comfort and sport switch (N72/1s3)

This switch controls Adaptive Damping System (ADS).

The switch with the indicator lamps is located in the upper part of the center console.

|

|

|

The ADS automatically selects the optimum damping for the respective driving conditions. At the same time the suspension is set to either sporty or regular.

The suspension tuning is set according to:

- Your driving style

- Road surface conditions

- Your choice of suspension style, "sport" or "convenience", which you select using the damping switch.

The following suspension styles are available:

- "Convenience" - both indicator lamps (1) are off.

- "Sports 1" - one indicator lamp (1) is on.

- "Sports 2" - both indicator lamps (1) are on (on vehicles produced after 09/99).

The selected suspension style is stored in memory, even after the SmartKey is removed from the starter switch.

Level control switch (N72/1s2)

|

|

This switch controls Airmatic Level control system.

The following vehicle level settings can be selected when the vehicle is stationary:

- "Normal" - for driving on normal roads. The indicator lamp (1) is off.

- "Raised" - for driving on rough roads or with snow chains. The indicator lamp (1) is on.

Select the "Raised" level setting only when required by current driving conditions. Otherwise the fuel consumption may increase and handling may be impaired.

The vehicle chassis ride height is raised or lowered according to the selected level setting and to the vehicle speed (these height adjustments are so small that you may not notice any change):

- With increasing speed, ride height is reduced by up to approximately 3/4 in (20 mm).

- With decreasing speed, the ride height is again raised to the selected vehicle level.

The selected vehicle level setting remains stored in memory even if the engine is turned off and restarted. However, the vehicle lowers to regular level when you exceed a speed of 75 mph (120 km/h) or maintain a speed of between 50 mph (80 km/h) and 75 mph (120 km/h) for more than 5 minutes.

This can be used to raise the vehicle level by 25 mm (20 mm USA). The raised level switch position is indicated by the red indicator lamp (1) in the switch. In addition, the multifunction display in the instrument cluster displays: "AIRMATIC VEHICLE RISING".

|

As long as the multifunction display in the instrument cluster shows the message: "AIRMATIC VEHICLE RISING", the desired vehicle level has not yet been reached. If the raising of the vehicle is cancelled due to the driving speed, the instrument cluster displays the following message for approx. 10s: "AIRMATIC LEVEL SETTING CANCELLED". If the vehicle is raised several times in quick succession, it may happen that the air compressor shuts down temporarily in order to prevent an overload. The raising sequence will then take an unusually long time.

Control Module (N51) - AIRmatic with ADS

Function - AIRmatic with ADS Control Module (N51)

To execute all control functions of ADS and AIRmatic.

Location - AIRmatic with ADS Control Module (N51)

AIRmatic with ADS Control Module (N51) is located in left fuse box.

Input Functions - AIRmatic with ADS Control Module (N51)

The AIRmatic with ADS Control Module (N51) receives input signals over CAN Bus from the following components:

- ESP control module

- Engine control module

- Transmission control module

- Instrument cluster

- Steering angle sensor

- ADS comfort and sport switch

- Level adjustment switch

- Three body accelerometers

- Two front axle level sensors

- One rear axle level sensor

- One Airmatic pressure sensor

Output Functions - AIRmatic with ADS Control Module (N51)

The input signals are converted in the AIRmatic with ADS Control Module (N51) to output signals for the following components:

- Four Level control valves

- One main reservoir charge valve

- Four ADS damper valves

- Multi-function display

- Switch indicator lamps

- Air compressor

|

|

Compressor Relay (K40/7kO) - AIRmatic

The Airmatic Compressor Relay (K40/7kO) is located in right fuse box, location 'O' (the first one next to the three 40 amp fuses).

The relay starts and stops the Airmatic compressor.

A faulty relay may cause the compressor to overheat thus damaging it.

The fuse 32 next to the relay protects the AIRmatic circuit.

Hella relays have proven to be reliable. For part number see [3].

|

|

Spring Strut (40, 41) - AIRmatic

The spring strut takes over all the functions of suspension, level control, level adjustment and damping to be carried out.

|

|

|

Design - Spring Struts (40, 41)

A single-tube gas-filled shock absorber is integrated into the spring strut. The ADS damper valve is attached to the spring strut.

|

Design - Front Axle Spring Strut (40)

Protective Boot and Bellows - Front Axle Spring Strut (40)

WIS is very confusing when it comes to identifying the bellows and the protective boot for the Front Axle Spring Strut (40).

In this example WIS identifies the Protective Boot as the Bellows. See item 7 in the next figure.

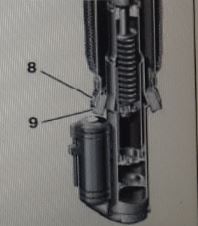

Air Spring Plunger and Support Bushing - Front Axle Spring Strut (40)

WIS also introduces the term "plunger" for the Front Axle Spring Strut (40).

The Air Spring Plunger is identified as item 8 in the next figure. It is the conical flared lower end of the protective boot.

Air Spring Plunger fits over the Support Bushing which is the conical seat identified as item 9 in the next figure.

Operation - Spring Struts (40, 41)

- When filled with air, the rubber air bellows (h) rolls up and down the alloy lower section strut tube (a).

- Without air the rubber air bellows (h) is allowed to kink and crease when depressed and under load would also have the top pressed hard into the inside of the air chamber (l).

- The only sliding action is in the strut damper unit which is oil filled and gas pressurized.

Function - Spring Struts (40, 41)

The weight of the vehicle is carried by the compressible air (l) sealed into the air bellows of the spring struts. The rolling hose air bellows (h) is made of rubber. Under dynamic load during driving, the air bellows rolls up parallel with the axis of the spring strut, thus providing the necessary spring travel. The roll-up zone on the spring strut is sealed off from the outside by a rubber boot (n) as a protection against dirt.

The vehicle level is raised/lowered by increasing/reducing the air pressure in the air chamber (l), which results in a lengthening/shortening of the spring strut (40). The spring strut incorporates a residual pressure valve (k) which blocks off the pressure chamber in the spring strut in the direction of the supply line in the event of a pressure drop at or below a residual pressure of 4-5 bar.

Replacements - AIRmatic Spring Struts (40, 41)

OEM - AIRmatic Spring Struts (40, 41

Front (without 4MATIC):

- A2203205113 (replaced by A2203202438)

- A2203202438

Front (4MATIC):

- Left: A2203202138

- Right: A2203202238

Rear:

- A2203205013

- A2203207913 (for option code Z04)

- A2203207813 (for option code Z07) (replaced by A2203202338)

- A2203202338 (for option code Z07)

OE (Bilstein) - AIRmatic Spring Struts (40, 41)

Since Bilstein is OEM manufacturer for W220 struts, it is possible to buy OE strut directly from Bilstein much cheaper. It is possible to purchase brand new Bilstein strut for $700.

- Front left (4Matic): 44-051518

- Front right (4Matic): 44-051525

- Front: 44-042295

- Rear: 44-042301

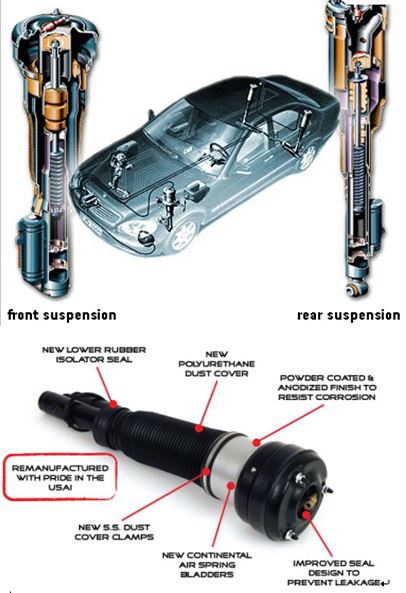

Arnott - AIRmatic Spring Struts (40, 41)

Arnott sells both new and remanufactured struts. It is possible to get 10% discount [4] when making order online.

Arnott claims [5] that their products use improved air spring bladder exclusively manufactured by Continental which provides longer lifetime than OE.

In fact, Arnott provides limited lifetime warranty [6] for their struts.

- Arnott Remanufactured. Arnott remanufactured strut cost $575 but it only has installed new rubber air bladders and not the shock piston seals or gas charge.

- Arnott New. Arnott new units cost $624. But with all new units you lose the electronic damping. While the new Arnott units allow you to plug in the original wire harness from the car, it simply fools the computer to thinking the selective damping is functioning. In reality it's not and the shock has constant damping setting corresponding to OE "comfort/convenience" setting ("sport 1" and "sport 2" damping settings are not available).

Adaptive Damping System (ADS II) - AIRmatic

Function - Adaptive Damping System (ADS II)

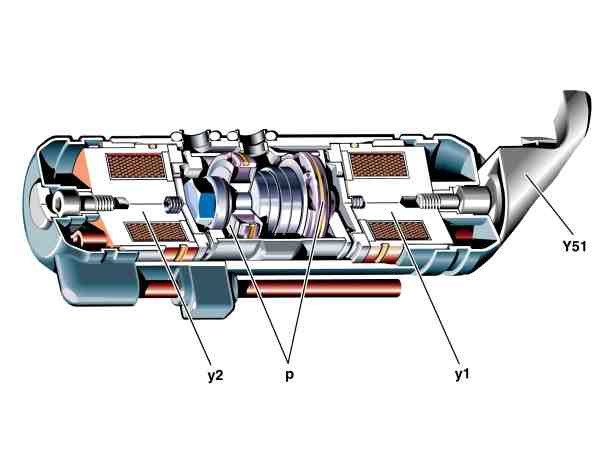

The Adaptive Damping System (ADS II) via the Damping Valve Unit (Y51, Y52, Y53, Y54) adapts the damping force to the driving style and road condition. The damping force is regulated in damping valves (Y51, Y52, Y53, Y54). Each wheel has one damping valve installed between the upper and lower chambers of the single-pipe gas-filled shock absorber.

Each damping valve contains two electromagnetic valves (y1, y2), allowing four different damping force settings according to how they are actuated via the AIRmatic with ADS control module.

The extremely short adjusting time (milliseconds) means that the optimum damping force setting is available almost immediately if sudden changes in the vehicle level are required, such as during an obstacle-avoidance maneuver.

|

|

|

Design - Damping Valve Unit (Y51, Y52, Y53, Y54)

- Y51 - left front axle damping valve

- y1 - front axle solenoid valve 1

- y2 - front axle solenoid valve 2

- p - piston reed valve pack

The Damping Valve Unit (Y51, Y52, Y53, Y54) consists of a casing and 2-piston reed valve packs (p). Located above are the spring-loaded solenoid valve pistons and the solenoids. The valve pistons and solenoids form the solenoid valve units (y1, y2).

If the solenoid valve coils (y1, y2) are not actuated, the spring-loaded solenoid valve pistons (y1, y2) keep the holes directly below them closed. Oil is displaced via the reed valve packs (p) and the oil duct located diagonally opposite in the casing.

If the solenoid valve coil (y1) is actuated, for example, the solenoid valve piston (y1) allows the hole to open and the oil can flow over this hole. Only a small amount of oil is displaced via the piston reed valve pack (p). The damping force levels are achieved by means of the differently positioned reed valve packs and controlling the solenoid valves.

Components - Damping Valve Unit (Y51, Y52, Y53, Y54)

Force Settings - Adaptive Damping System (ADS II)

The ADS suspension control module is used to achieve four different damping force settings:

- Damping force setting 1

- For comfortable rolling with small sprung mass vibrations and low longitudinal and lateral acceleration. With this damping force setting both solenoid valves y1 and y2 are open so that most of the oil flows parallel to the hard rebound and compression of the operating piston via the softer reed valves at the solenoid valves. The comfort rebound and compression setting is therefore achieved.

- Damping force setting 2

- The reed valves at the valve piston generate a firmer setting. If the vehicle is lowered, solenoid valve y2 is opened and solenoid valve y1 is closed. The reed valves (a = hard compression and b = soft rebound) at solenoid valve y1 generate a hard compression and a soft rebound.

- Damping force setting 3

- The reed valves at the valve piston generate an even firmer setting. If the vehicle is raised, solenoid valve y1 is opened and solenoid valve y2 is closed. The reed valves (c = hard rebound and b = soft compression) at solenoid valve y2 generate a hard rebound and a soft compression.

- Damping force setting 4 (driving safety setting)

- For increased driving safety with high longitudinal and lateral vehicle acceleration. Both solenoid valves y1 and y2 are closed. The reed valves (a = hard compression and c = hard rebound) generate a hard compression and rebound. All the oil flows via the hard rebound and compression of the operating piston. This damping force setting is also selected if the ADS system fails and the ADS suspension warning light (A1e27) comes on in the instrument cluster.

| Damping force setting | Damping valves (Y51-Y54) | Valve control | ||

|---|---|---|---|---|

| Rebound | Compression | Solenoid valve (y1) | Solenoid valve (y2) | |

| 1 | Comfort | Comfort | Open | Open |

| 2 | Soft | Hard | Closed | Open |

| 3 | Hard | Soft | Open | Closed |

| 4 | Hard | Hard | Closed | Closed |

Multifunction display (A1p13)

Various messages concerning the AIRmatic and ADS are shown in the multifunction display in the instrument cluster and in the comfort and sport and level adjustment switches.

AIRMATIC VISIT WORKSHOP!

|

|

In the event of electrical faults in the AIRmatic or ADS system, the following message appears on the multifunction display in the instrument cluster: "AIRMATIC VISIT WORKSHOP!". The fault is stored in the ADS suspension control module and can be read out using the diagnosis tool.

Limp-home function A malfunction in the adaptive damping system causes the ADS to shut down. The suspension is switched to the hardest setting. In the event of a fault in the suspension system or in the level adjustment system, the vehicle attempts to maintain the set level. Manual and automatic level adjustments are no longer possible.

AIRMATIC STOP, CAR TOO LOW!

If the vehicle level at the front axle is more than 50 mm (60 mm USA), or at the rear axle more than 60 mm (70 mm USA) below the normal level, the multifunction display in the instrument cluster displays the warning: "AIRMATIC STOP, CAR TOO LOW!". The display disappears again when the level has risen back to 48 mm or 58 mm (58 mm or 68 mm USA) respectively below the normal level.

Issues and Solutions - AIRmatic

Pneumatic Leaks - AIRmatic

The most common problems are mostly associated with the following:

- AIRmatic Compressor Unit (A9/1) failure or partial failure.

- AIRmatic Level Control Valve Unit (Y36/6) on top of the AIRmatic Compressor Unit (A9/1) fails (very common).

- Valve failure on rear suspension strut. Often the problem lies in bad connection between the strut and Airmatic control module.

- The seals at the tops of the front suspension struts develop leaks. This issue was more common with the older design in the pre '03-ish W220's compared to those from a few years later. The newer models and ones which have been modified with new replacement parts do not leak. There is available epoxy repair kit that can be used to close the cracks.

- The high-pressure line from the AIRmatic Compressor Unit (A9/1)to the AIRmatic Level Control Valve Unit (Y36/6) develops a leak. In this case replacement line or a repair joiner can be used.

Note: If the AIRmatic leaks substantially it is imperative that it be fixed as soon as possible or else the AIRmatic pump may burn out. If the leak cannot be fixed immediately remove the AIRmatic compressor relay (K40/7kO) to disable the AIRmatic Pump.

Leaking Top Seal - AIRmatic Front Struts

If your front struts are leaking at the upper seal, there is a repair kit - around $550 parts and labor for both sides.

Leaking Struts - AIRmatic

If any struts need replacement, Arnott Industries has a more durable strut, new or remanufactured, at much less cost compared to OE. See Arnott Industries or DIY Repairs section below.

Lower Dust Cover Failure - AIRmatic Spring Strut

On older and higher mileage vehicles the lower dust cover on an Airmatic strut starts to wear and fail. This plastic dust boot is designed to prevent dirt and contamination getting to the air spring bladder. After around 100,000 miles (130,000Kms) they often show signs of cracking and tearing. Failure to replace means the end is near for the whole strut.

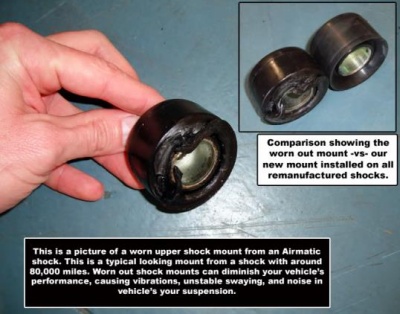

Upper Mount Failure - AIRmatic Spring Strut

The next image shows a typical worn upper mount removed from a shock with around 80,000 to 100,000 miles (130,000KM to 161,000Km). A worn mount will contribute to many unwanted problems with your suspension.

Troubleshooting - AIRmatic

"AIRMATIC VISIT WORKSHOP!" message on the instrument cluster

This message is shown in the event of electrical faults in the AIRmatic or ADS system. Use DAS to read error codes. For a complete list of list of the Mercedes-Benz Fault Error Codes/Diagnostic Trouble Codes (DTC) for 1996+ models see here M-B Fault Error Codes/Diagnostic Trouble Codes (DTC).

| Error Code | Description | Probable cause |

|---|---|---|

| C1324-001 | Fault in component Y53y1 (Left rear solenoid valve 1) in assembly Y53 (left rear axle damping valve unit) | Could be caused by faulty solenoid valve in the strut in which case the strut or strut's damping valve unit should be replaced.

If the error code comes in pair with second selenoid valve of the strut then the problem is very likely in the connection. Check the electronic connection between the strut and AIRmatic with ADS control module (N51). |

| C1325-001 | Fault in component Y53y2 (Left rear solenoid valve 2) in assembly Y53 (left rear axle damping valve unit) | See above. |

"AIRMATIC STOP, CAR TOO LOW!" message on the instrument cluster

|

|

Note: If the Airmatic leaks substantially it is imperative that it be fixed as soon as possible or else the Airmatic pump may burn out. If the leak cannot be fixed immediately remove the Airmatic compressor relay (K40/7kO) to disable the Airmatic Pump.

Compressor is dead

To test this hypothesis start the car and see if compressor is running (you should hear compressor in the front right fender running). If it is not running check Airmatic fuse and relay (see section above). Faulty relay may cause compressor to run nonstop which will cause compressor to overheat and blow out the fuse.

Strut is leaking

Most common reason for car being too low is a leaking strut. Usually the leak develops in the rubber air bellow. If the leak is severe, a hissing sound can be heard from the wheel house area. The faulty strut can be located visually by measuring the height. It is very likely that the wheel on the other side (or the wheel on other axle on the same side) will also be brought down significantly, but usually to a bit smaller extent. Note, that the same symptoms can be observed also if the line to the strut is faulty or valve block is faulty (see below), since strut itself has a residual pressure valve which will block air out of strut only in the event of a pressure drop at or below a residual pressure of 4-5 bar, which will not be visually distinguishable from a completely empty strut.

Line to strut is leaking

It is possible that line to the strut develops cracks or microcracks. In case of front struts the line from valve block to strut can be tested with spray test. However, in case of rear struts the line goes from the valve block to rear through interior and thus is not reachable. Simple test is to run an alternative line from the valve block to the strut to check if the original line is faulty (see section on the line repair). If the crack is large it may suffice to push air in the line and locate damaged point by hearing hissing sound.

Valve block is leaking

It is possible that valve block fails to close some valve in which case the pressure will be released back to air compressor and out of the system. Check section "Inspecting level control valve unit (Y36/6) for leaks" below [7] on how to inspect valve block for leaks.

Usually, in case of valve block leak the vehicle will not be completely down, since residual pressure valve inside the struts will prevent pressure drop below pressure of 4-5 bar.

Central reservoir is leaking

To test whether central reservoir can keep pressure DAS can be used which has a pressure test for reservoir. If test shows that reservoir cannot keep the pressure, before replacing it, check with spray test if the line to reservoir is not faulty.

Level sensor is faulty

There are two level sensors for each front wheel and one for the rear axle. If the level sensor reports wrong height the system will think that vehicle already has the required level and will not rise the vehicle. Information reported by level sensors can be viewed using DAS. If the vehicle rises, but then falls down again, the level sensors are likely not the cause.

Vehicle level is too high

Level Control Valve Unit (Y36/6) is leaking

It is possible that Level Control Valve Unit (Y36/6) fails to close some valve in which case the pressure will be released back to strut rising the car too high. The vehicle is high only while the car is off, since as soon as vehicle is started the computer will try to adjust the level to the programmed level.

Level sensor is faulty

There are two level sensors for each front wheel and one for the rear axle. If the level sensor reports wrong height the system will think that vehicle level is too low and will rise the vehicle above normal height. Information reported by level sensors can be viewed using DAS.

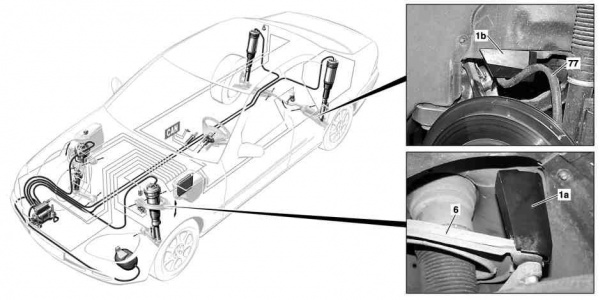

Emergency Procedure - AIRmatic

In case of "AIRMATIC STOP, CAR TOO LOW!" warning on the instrument cluster, the vehicle should be stopped immediately and measures taken.

Possible consequences of riding with leaky strut:

- The compressor will run endlessly which may cause compressor burnout.

- If the front is low, the tire will rub the inner fender.

- There is a risk of damaging other strut on the same axis.

There is a temporary fix for front struts, which can be used to get to the closest workshop:

|

|

|

|

The ride will be little bumpy, but not much harsher than it is when pushing the button that stiffens the suspension.

Original limp-home buffers

|

|

Front axle

Mount limp-home buffer A2203271230 (1a) onto upper transverse control arm (6). Slowly lower vehicle and make sure that the limp-home buffer makes contact with top of wheelhouse.

Rear axle

Slide limp-home buffer A2203280839 (1b) in between body fold and torsion bar (77). The body fold must lie in the groove of the limp-home buffer. Slowly lower vehicle and make sure that the torsion bar (77) makes contact with the limp-home buffer (1b).

Tips - AIRmatic

- Depressurise AIRmatic components (suspension struts, valve unit, main memory) before removal using STAR Diagnosis. The components or the entire system must NOT be discharged by unscrewing pressure line connectors.

- Soiled pressure line connectors must be cleaned before unscrewing.

- Mark the Level Control Valve Unit (Y36/6) with the colours of the air lines BEFORE removing them to avoid having to print out the guide in section "Air Line Colour Codes - Level Control Valve Unit (Y36/6)" below. [8].

- Seal off the exposed pressure line ports immediately with blind plugs if possible.

- Seal off the pressure lines immediately by placing the exposed ends in small plastic bags sealed with tape to keep clean.

- Only use flare nut wrenches or special tools to unscrew the pressure lines.

- Replacing one stut at a time is possible as long as the valve block has no problems. The valve block has a valve for each strut supply pipe and if the valves remain closed then no air will leak from the other struts whilst one strut is off. But Be Warned, if the valve block is faulty then any of the struts could loose air after releasing the supply line from a strut.

- The Allen screws holding the bottom of the strut use loctite thread fastener so a little heat from a gas torch always does the trick in breaking the sealant.

- When reinstalling a strut ensure that the plug at the electrical connection is pressed home firmly.

DIY Repairs - AIRmatic

Before attempting any DIY repairs make sure to read the "Tips - AIRmatic" section above.

Replacing Relay K40 7kO - AIRmatic

The OEM relays were Hella relays. Part number AR4 007 791-13 (M-B A002 542 72 19 or 0025427219).

Replacing Front Axle Spring Strut (40) - AIRmatic

If a replacement Front Axle Spring Strut (40) has been procured it is quite an easy task to swap them over. (And as long as the Level Control Valve Unit (Y36/6), commonly called the Valve Block hasn't failed, it is possible to do one side at a time.

Method - Replacing Front Axle Spring Strut (40)

In summary the steps are:

- Depressurise the AIRmatic system using STAR DAS.

- Jack up the car.

- Support the car on stands.

- Remove the wheel.

- Apply heat to the bottom Allen key bolts (see below for more detail).

- Loosen the bottom Allen key bolts.

- Remove the electrical plugs.

- Split the upper ball joint (see below for more detail).

- Remove the airline.

- Protect the exposed end of the airline from contamination.

- Remove the upper mounting nuts.

- Remove the strut. If you are lucky the old strut will pretty much fall out, especially if it has collapsed.

- Install the new strut. It should slip in with ease.

- Tighten the upper mounting nuts.

- Pry down the lower control arm.

- Set the bottom of the strut in place.

- Tighten the bottom bolts.

- Plug in the electrical connection firmly.

- Install the upper ball joint.

- Install the air line.

- Reinstall the wheel.

- Jack the car up slightly higher.

- Remove the stand/s.

- Lower the jack so that the car is at normal vehicle height.

- Leave for 2 minutes to stabilise.

- Press the Raise Button or Level Control Switch (N72/1s2).

- The car should lift off the jack.

- Remove the jack.

- Press the Raise Button or Level Control Switch (N72/1s2).

Tutorials - Replacing Front Axle Spring Strut (40)

Excellent replacement tutorials for the front struts are available here:

- http://www.bilsteinus.com/fileadmin/user_upload/user_upload_us/pdfs/E4-WM5-Y328A00_01.pdf (DE/EN)

- http://info.bilsteinus.com/mercedes/ (videos)

Separating front strut from ball joint

The Airmatic front strut is attached to the ball joint of the lower suspension arm with two stub screws (5mm hex) on the bottom of the spring strut.

|

|

|

Removing Allen Key Screws

Several people have reported screw removal resulting in several broken hex wrenches, frustration or even stripped set screws that had to be drilled out.

A very effective method to remove the screws is to use heat from a blow torch. A micro torch provides a nice small sharp flame that is easily controlled as to not cause any collateral damage.

|

|

|

Leaking Front Strut Air Spring - Repair Options

Note: Air suspension struts on which the air spring plunger (7) is separated from the support bearing (picture 1 below) can be filled with air and repaired again without problems. They do not necessarily need to be exchanged for a new suspension strut.

The front strut air spring is shown in the next figure. The lower flared conical part of the air spring protective boot (n) in diagram above is referred to in WIS as the "Air Spring Plunge". The conical shaped seat for the plunger is referred to in WIS as the "Support Bushing" or the "Support Bearing".

A common issue when a front strut deflates completely and the car is then jacked up so that the strut is full extended is that the air spring plunger (7) separates from the support bearing (picture 1 below). For a spring strut to deflate completely there may be a catastrophic failure of some internal component such as the air bellows, (h) in the diagram above, but it can also mean that the residual pressure valve (k) can be leaky so that the strut deflates over time. This residual pressure valve (k) normally blocks off the pressure chamber in the spring strut in the direction of the supply line and closes at or below a residual pressure of 4-5 bar. For a leaking residual pressure valve (k) to cause a full deflation, the air supply line or the relevant valve in the Level Control Valve Unit (Y36/6) would also need to be leaking.

A leaking Level Control Valve Unit (Y36/6) on its own should not cause the strut to deflate completely as the residual pressure valve (k) should be fully closed below 4-5 bar.

Before replacing a supposed leaky suspension strut, in each case carry out a leak test on the head bearing using soapy water.

If there is a lack of pressure in the suspension strut it may be that in the full rebound travel condition the air spring plunger (7) separates from the support bearing (picture 1).

In this case to test whether there is leakage at the head bearing, proceed as follows:

- Fill the air spring (using the DAS or other means), and in the process pull the air spring plunger (7) of the air spring downwards firmly by hand so that the air does not escape between the air spring plunger and the support bearing (picture 2 and 3).

- Once the suspension strut is filled, carry out the leak test on the head bearing and repair if necessary. A repair kit is available for this purpose.

- After using the repair kit proceed as described above when filling the air suspension strut (picture 2 and 3) ie pull the air spring plunger (7) firmly downwards by hand so that the air does not escape between the air spring plunger and the support bearing.

Replacing air spring for strut

|

|

|

A very common reason for a leaking strut is damage in strut's rubber air bellow (bladder). The damage is caused from the air spring chafing against the aluminum protective can over time. The original air bellow is made from a very thin single nylon cord layer the vertical weak spots or lines that will eventually pop through causing a complete failure. Unlike the OE air bellow, remanufactured rubber usually uses 2 ply design that prevents vertical wear points and the air bellow is usually over 2 times thicker than the original bellow.

|

|

It is possible to replace damaged air bellow, however, the rubber air bellow is attached to strut tube and strut top with crimp rings. This requires access to hydraulic press, which is not something that is easily available. Fortunately, it is possible to purchase on eBay air spring of the strut (the top part of strut) for around EUR 120 and mount it to damper unit (the lower part of strut).

Dismantling - Front Axle Spring Strut (40)

Identification of Parts Refer to Section "Components - AIRmatic" above [9] to identify the part names for the front sprint strut (40).

Removal

- Remove the epoxy and the residual pressure valve (k).

- With the home-made strut top seal tool press the top seal down enough to remove the lock ring.

- Insert a screw or similar device part way into the nylon cover which can then be pulled out.

- Use an air impact driver to undo the lock nut on the top of the damper piston rod (e).

- Remove the complete air spring from the damper unit.

Top Plate Internal View The next Figure shows the inside of the top of the strut.

- The yellow arrow points to the hole for the damper piston rod (e).

- The blue arrow points to the inside of the mount for the rubber air bellows (h).

- The red circle shows the brass air inlet to the air spring.

Reinstallation

- Fasten the air bellows (h) to the strut top using the 1st crimp ring.

- Install the strut tube (a) into the air bellows (h) and secure with the 2nd crimp ring.

- The next Figure shows the rubber air bellows (h) which is mounted on the outside of the air spring and is held in place by metal crimp rings.

- Notes:

- The bottom end of the lower strut tube (a) is tapered which is for sealing to the damper.

- The Airmatic strut can leak air from the bottom of the lower section if not seated against the rubber of the damper unit correctly.

- If you have a strut leaking from either the top or bottom of the rubber air bellows or a tear in the bellows itself you will most likely need a new air spring assembly. To replace the just the air bellows (h) you will need a hydraulic crimper and most DIYers will not have this tool.

- Check the Seal between the damper and the air spring.

- Install top dust cover.

- Insert the damper into the air spring.

- The next Figure shows a close-up of the strut damper with the bump stop buffer (i) and bump stop cover. The damper is fitted after the air spring has been assembled. It slides through the strut top and has the lower top seal and nut fitted followed by the nylon cover and then the top seal and lock ring. Note the large tapered rubber mount which provides the air spring to damper seal.

- Prepare the strut top plate.

- The next two figures show the top seal in place and the lock ring ready to be fitted using the home-made strut top seal tool.

- Final step is to re-install the residual pressure valve (k) using the modified ½” spanner.

Tools Required

- Commercial strut top seal tool. For an example see [10]

- DIY home-made strut top seal tool. Here is how to make one from a 150mm x 150mm piece of 6mm (1/4") steel plate.

- Accurately mark up the steel plate and drill three 8mm holes to match the pitch circle diameter (pcd) of the strut top plate mounting bolts.

- Drill one 10mm hole in the center.

- Obtain three off 120mm long 8mm bolts for the three 8mm holes.

- Use three 8mm joiner nuts to attach the 8mm bolts to the strut top.

- Obtain one off 150mm long 10mm bolt for the center 10mm hole.

- Thread a nut right to the top of the 10mm bolt and add a flat washer with a little bit of grease.

- Once fitted, tighten the nut to the plate and this will wind down the bolt for removal/replacement of the snap ring and the top seal.

- Impact driver

- DIY modified ½” spanner ground down to fit the air valve.

Replacing Compressor Unit - AIRmatic

Observe the location of the electrical and pneumatic connection points on the AIRmatic Compressor Unit.

|

|

- If possible depressurise the AIRmatic system using STAR DAS.

- Disconnect battery.

- Remove engine compartment paneling (right front part only).

- Unscrew pressure line connection (1) from AIRmatic compressor unit (A9/1).

- Detach connector on AIRmatic pressure reduction valve (A9/1y1).

- Disconnect connector for air compressor motor (3).

- Pull intake hose with air filter (2) out of longitudinal member.

- If the air filter (2) is replaced, the arrow on the air filter (2) must point towards the longitudinal member.

- Unscrew nuts (arrows) and remove AIRmatic compressor unit (A9/1).

- Detach air compressor relay (K40/7kO). Only when installing a new air compressor. When replacing the air compressor the air compressor relay (K40/7kO) should always be exchanged as the switching contacts may be predamaged.

- Install in the reverse order.

Inspecting AIRmatic Level Control Valve Unit (Y36/6) for leaks

General leak testing - Level Control Valve Unit (Y36/6)

Leak Testing - Using STAR

STAR Diagnosis System offers an easy and thorough method for testing the AIRmatic.

Using SDS navigate to AIRmatic Pneumatic Tests.

The following tests are available;

- A9/1 Compressor Test

- Y36/6y1 Left Front Strut Test

- Y36/6y2 Right Front Strut Test

- Y36/6y3 Left Rear Strut Test

- Y36/6y4 Right Rear Strut Test

- A9/1y1 Pressure Relief Valve Test

- Leak test between compressor and valve block (Level Control Valve Unit (Y36/6)), ie the 'P' valve and line).

- Leak test between valve block and suspension struts.

- Leak test between valve block and central reservoir.

- As an example this last test does the following;

- Central reservoir charge valve (in valve block) is opened.

- 'P' (in valve block) valve is opened.

- All other valves (in valve block) are closed.

- Compressor is turned on for <60 secs.

- Compressor is turned off.

- 'P' valve (in valve block) is closed.

- Central reservoir pressure is monitored for leakage for 120 secs.

- The Central reservoir pressure must not drop by more than 0.5 bar in that time.

- As an example this last test does the following;

Sample Results of Leak Testing - Using STAR

1. Leak test between compressor and valve block (Level Control Valve Unit (Y36/6)), ie the 'P' valve and line).

As an example the following result was obtained for a leak test of the 'P' valve and line. This is similar to the "bubbles" test shown below.

- After all valve block valves were closed the compressor produced 10.56 bar within 10 secs which is withing the specification of 10 bar within 40 secs.

- After the compressor was turned off the initial compressor pressure ('P' line) = 10.56 bar.

- After the 120 elapsed time the final compressor pressure ('P' line) = 5.30 bar.

- Thus the measured leakage rate was 5.26 bar in 120 secs which is OUTSIDE the specified 0.5 bar in 120 secs.

- SDS reported that there was a leakage in the 'P' valve or the high pressure line between the compressor and the valve block.

A squirt of some soapy solution on the high pressure line between the compressor and the valve block proved that the line and its associated connectors were not leaking. Thus the fault was a leaky internal 'P' valve in the valve block. Once the 'P' valve connector was removed from the valve block, a simple test by applying a soapy finger over the port prodcued obvious positive pressure of air escaping from the port, thus confirming the diagnosis of a leaky internal 'P' valve in the valve block.

Unfortunately the valve block can not be dismantled for inspection and cleaning and a new Level Control Valve Unit (Y36/6) was required.

2. Leak test between valve block and central reservoir.

As another example the following result was obtained for a leak test between valve block (Level Control Valve Unit (Y36/6)) and central reservoir.

- Initial Central Reservoir pressure = 12.07 bar reached in 60 secs.

- After Compressor turned off the Central Reservoir pressure = 10.84 bar.

- After 120 secs elapsed time the Central Reservoir pressure = 10.57 bar.

- Conclusion: This real world Central Reservoir and its associated supply line after 220,000Km produced a leakage rate of 0.27 bar in 120 secs, which is well within the specified 0.5 bar in 120 secs.

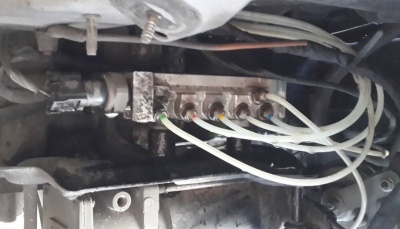

Leak Testing - Without STAR

Here's how to do a general leak test.

- 1. On the right-hand side of the vehicle remove part of the wheel house inner panel in front fender.

- 2. Spray the pressure line connections 1, 2, 3, 4, 5, P of the level control valve with leak detecting spray.

- 3. Inspect for an indication of leaking. Severe leaks are evident immediately.

- 4. Wait for approx. 10-15 minutes after spraying and reinspect. This means that minor leaks can be recognized (forming a white cap).

|

|

|

Test for internal leak - Level Control Valve Unit (Y36/6)

Common failure mode of the level control valve unit (Y36/6) is when some valves fail to close thus releasing the air out of system through the P valve or through other valves back to struts.

Here's how to do a test for an internal leak.

- 1. On the right-hand side of the vehicle remove part of the wheel house inner panel in front fender.

- 2. Test whether the P valve allows air to release.

- 3. Detach the P line connection at the air compressor end and spray it with leak detection spray or immerse the end in a soapy solution.

- 4. After the test use compressed air to clean the valve.

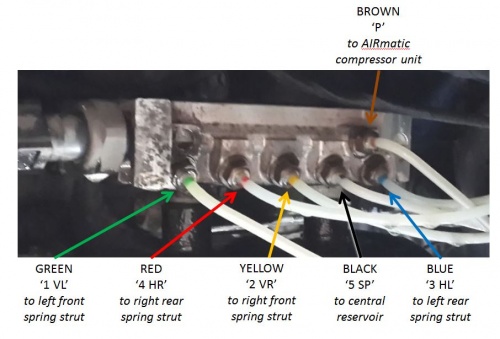

Air Line Colour Codes - Level Control Valve Unit (Y36/6)

As seen in next photograph; Green, Red, Yellow, Black, Blue, with 'P' line above the others, Brown.

Air Line Designations - Level Control Valve Unit (Y36/6)

Line repair - AIRmatic

The leak may also develop in any of Airmatic pneumatic lines. The lines to the rear struts go through the interior and it is difficult to find the leak unless the crack is large enough so that the crack can be located thanks to loud hissing sound. Alternative line can be run from front valve block to the rear to test if the line is faulty.

|

|

|

|

|

MB sells the air line (pipe/hose) in 5 ft lengths, maximum. From the factory air line is built with continuous length of line with no joins. 5 ft lengths are just for repairs. However, you can buy aftermarket 4mm lines of any length and much cheaper than OEM lines. MB also sells air line repair connector (junction/fitting) A0003270169 which can be used to connect air line. However, there is available cheap and reliable plastic "push in" connector which can be used to easily connect air lines without any tools.