Seat heating and ventilation: Difference between revisions

Ricebubbles (talk | contribs) (Rearranged laylout) |

m (Pokseva moved page WIS 91.30 Seat Heater, Seat Ventilation to Seat heating and ventilation) |

(No difference)

| |

Revision as of 14:39, 2 August 2017

Seat Heater

Description - Seat Heater

Seat Heating in a W220 S-Class is optionally available in both front seats (Option Code 873) and as an additional option, in both rear seats (Option Code 872).

The seat heater is activated by push button controls on the relevant door panels.

Function - Seat Heater

Front Heated Seats

The left/right front heated seats allow the seat cushion and the backrest to be heated in two heating stages.

The operating states are indicated by two LED's located above the push button controls on the relevant door panels.

The seat heating is produced by a resistance wire sewn into the seat cushion. Similarly a resistance wire is sewn into the backrest.

The resistances wires are supplied with pulsed voltage (frequency 20 - 30 Hz) supplied from either the left front seat adjustment control module with memory (N32/1) or the right front seat adjustment control module with memory (N32/2).

The ON/OFF ratio for the pulsed voltage is 27% in heating stage 1 and 100% in heating stage 2.

Switch off can be accomplished either manually by pressing the push button control or time controlled via the associated control module.

Rear Heated Seats

The rear heated seat function is identical to the front heated seats.

The left rear door control module is designated N69/3 and the right rear door control module is designated N69/4.

The pulsed supply voltage for the rear seats is supplied by the rear seat control module (N25/6).

Issues - Seat Heater

A common issue is a broken resistance wire, especially where the wires are constantly flexing at the seat edges nearest the door.

With a bit of patience the break can be found and repaired. Alternatively the resistance wire can be left in place and an aftermarket seat heater retrofitted.

DIY Repair- Seat Heater

This DIY repair assumes the seat heater is not working due to a broken resistance wire and that the seat has been removed from the car and dismantled.

The resistance of the resistance wire can be tested using an suitable digital multimeter (DMM). Obviously a broken resistance wire will show an open circuit. A resistance wire in good condition is about 3 - 5 Ohms.

To repair a broken resistance wire it is first necessary to find the exact location of the break. This is made difficult because the resistance wire is covered with an insulating surface.

- 1. Connect one side of the DMM to one end of the resistance wire.

- 2. Connect the other side of the DMM to a sharp instrument such as a scalpel blade.

- 3. Carefully cut through the insulation covering the resistance wire until an electrical contact with the wire is made at approximately the mid point of the length of the wire.

- 4. If a resistance is observed then the break is obviously in the other half of the wire in which case transfer the DMM connection to the other end of the resistance wire.

- 5. If there is an open circuit seen in the first measurement or you are starting again from the other end then repeat the process by cutting through the resistance wire at the half way point again (this will be at approximately the quarter point of the wire closest to the DMM).

- 6. Keep repeating the process until you have narrowed down the point of the break to a few millimeters.

- 7. Cut the resistance wire at this point.

- 8. Crimp in a new short joining piece of insulated wire to connect the broken ends. (Note you must use a crimp connector as the wire will be getting hot.)

- 9. Finally test the resistance of the resistance wire from end to end to check that the break has been repaired.

Seat Ventilation

Description - Seat Ventilation

Seat Ventilation in a W220 S-Class is optionally available in both front seats (Option Code 401a) and as an additional option, in both rear seats (Option Code 402a).

The seat ventilation is activated by push button controls on the relevant door panels.

Note they are ventilators and not really coolers. It appears M-B research has shown "prolonged use of cooled seats as opposed to ventilated seats, promotes back pain".

Function - Seat Ventilation

The idea of seat ventilation is to cool the contacted seat area by blowing air over the inside of the seat cushions (directly towards the occupant) thus removing some of the driver or passenger's body heat and reducing the 'sticky' back or behind effect which is common on a hot day. They are particularly useful if you need to wear a suit in the car on a hot day.

The seat ventilation is achieved by means of an electronically controlled fans in the various seat bases and seat back rests. In the W220 there are four fans in each ventilated seat base and six fans in each ventilated seat back rest. (To be confirmed.)

The seat base fans suck internal cabin air from under the seat and blow it over the inside of the base seat cushions (directly towards the occupant). The leather seat covers have small perforations to enhance the air flow cooling effect.

The seat back-rest fans suck internal cabin air through vertical inlet ports in the rear of the seats and blow it over the inside of the back-rest seat cushions (directly towards the occupant). The leather seat covers have small perforations to enhance the air flow cooling effect.

A slight improvement in seat cushion ventilation performance can be obtained by directing air conditioned air to the foot rests so that the seat ventilation fans pickup this cooler air.

Tests - Seat Ventilation

To check if the seat ventilation is working, switch off everything making a noise in the car and listen at each seat while you switch on and off the seat ventilation. The fans can be just heard running if everything is very quiet.

Issues - Seat Ventilation

No Seat Ventilation

W220 commonly experience failed seat ventilation in either one or more base seats and back rests.

A common failure mechanism is for the fan supply wires to break and go open circuit. It is a relatively easy fix to remove and dismantle the seat and repair the broken wire/s.

Poor or Weak Seat Ventilation

The OEM seat ventilation fans look very similar to 1980's style personal computer cooling fans and are rather small and weak looking.

The general opinion is that the seat ventilation is hardly noticeable. This is a typical criticism of the OEM design; "M-B figured out a way to make quad zone climate control and even vents in the B pillar in the back. But they couldn't get the damn vented/ac seats to work well."

Some M-B enthusiasts have replaced the original relatively small fans with larger fans and stated "it's WORTH the damn time, what an awesome mod!", and "I drove around for the last 3 days with this mod, and I LOVE IT. It did make a big difference, now I can feel cooler air through a tee shirt or even through a long sleeve shirt, so much so, that after 15 minutes or so, I have to lower the fan speed to avoid it being too cold. And noise is not an issue even at full speed, as it is drowned with the engine noise and radio."

OEM Performance - Seat Ventilation

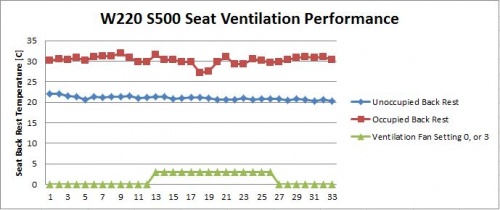

In an attempt too quantify how well the OEM seat ventilation worked in a W220 S500, BenzWorld member ricebubbles measured the temperature of the seat back rests for an occupied and an unoccupied seat and with the ventilation fans off and then on their maximum setting. The back rest of the occupied seat was of course warmed by the occupant's body heat.

Measurement Conditions

The measurement conditions were:

- Ambient temperature 17.5C.

- Car driven with engine at operating temperature, then tests performed with car stationary, in full shade, and with engine at idle.

- Car interior temperature stabilised with ACC at 21C left and 21C right. ACC fan set to Auto and showing two bars.

- An infrared remote sensing thermometer was used to measure the seat back temperatures.

- For the occupied seat, the occupant moved slightly forward and to one side thus exposing the back rest for just long enough to take a radiometric measurement.

- Radiometric measurements were taken at one minute intervals and the results recorded in a spread sheet.

Results

The average temperature results were:

- Unoccupied Back Rest temperature (no ventilation) 21.1C.

- Occupied Back Rest temperature (no ventilation) 29.9C and 30.4C.

- Occupied Back Rest temperature (with maximum ventilation) 29.7C.

Conclusion

The only possible conclusion is that the OEM seat ventilation makes hardly any measurable difference which is supported by anecdotal evidence that from the occupant's point of view there is no discernible cooling effect.

The DIY modification to fit larger fans is thus looking very appealing.

DIY Fan Replacement - Seat Ventilation

The method involves purchasing slightly larger fans and trimming away as some fan and seat padding material to mimic the form of the original fans and their mounting holes, only in a slightly larger size to suit the replacement fans.

After doing the modification another M-B DIYer stated "it now actually gives purpose to the feature and utility to be able to lower the ventilation settings (before I used high or nothing)".

With acknowledgement to BenzWorld members bobgodd, timeToy, berti_00 et alia for developing a seat ventilation improvement modification and for documenting the steps.

Refer to:

http://mbworld.org/forums/w211-amg/399806-vented-seats-not-so-vented-anymore-3.html

http://mbworld.org/forums/w211-amg/448120-diy-vented-upgraded-seat-fans.html

Part Numbers - Seat Ventilation Fan Replacement

Note the E-Class and S- Class have different seats. The details for an E-Class are provided as a guide only.

For an E55, the stock fan is a Papst, PBT-GF20-FR size is 60x60x10mm. DIYers suggested for higher performance replacements use either 80mm or 92mm fans which are no more than 15mm thick and preferably the Delta EFC0812DB-F00 which is a good replacement.

http://www.cwc-group.com/efc0812dbf00.html

with specification;

- Delta EFC0812DB-F00

- Dimensions: 80x80x15mm

- Voltage: DC 12V

- Current: 0.33A (Max. 0.50A)

- Input Power: 3.96W

- Speed: 3800 RPM

- Air Flow 48.8 CFM

- Noise: 41 dBA

- Bearing: Ball

- Features: PWM, Speed Sensor (Tach)

- Termination: 4-Wire / 12-Inch, (-)Black, (+)Red, (RPM)Blue, (PWM)Yellow

- Datasheet: EFC0812DB-F00 PDF http://site.cwc-group.com/specifications/18408-efc0812dbf00.pdf

- Packaging: Each master box contains 168 pieces, item sold as an individual piece

Note the blue and yellow wires are not used.