Airmatic

Description - WIS 32.22 Air Suspension / Airmatic

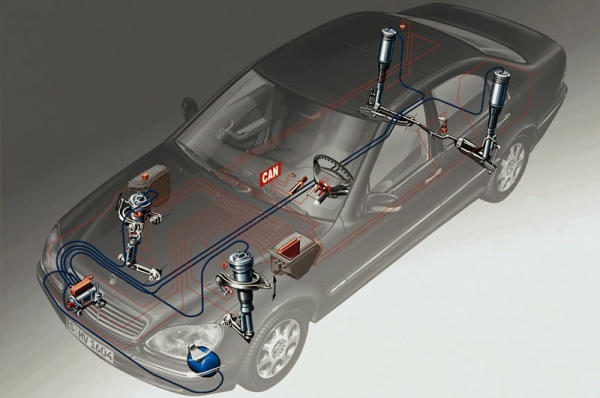

The W220 Airmatic system is a fully supporting air suspension system which provides both static and dynamic support by means of four air bellows located at the wheels.

Features - Airmatic

- Level control both manual and speed sensitive.

- Electronic level control which maintains a constant even level at the front and rear axles according to the driving and vehicle load conditions.

- When the vehicle is stationary the level is readjusted if there is a difference of more than +/- 10mm after a door or the trunk lid is opened.

- While driving the level is readjusted if there is a difference of more than +/- 20mm. The level is adjusted to +/- 10 mm every 15 minutes.

- Active Damping System (ADS) which changes the damping forces according to the road conditions and the driver's driving style. The road conditions are determined by vertical acceleration sensors in the body of the vehicle. The horizontal acceleration is determined by measuring the vehicle speed and turn angle.

Advantages - Airmatic

Higher level of driving safety and ride comfort due to:

- Adapting damping to road conditions and driving style.

- Low location of centre of gravity as vehicle lowers above 70KPH.

- Low aerodynamic drag and fuel consumption as vehicle lowers above 70KPH.

- Less tendency for vehicle to lift at speed.

Individual adaptation due to:

- Raising vehicle level for poor road surfaces and when negotiating driveways.

- Two possible damping levels for comfort or sport driving styles in vehicles produced up to 08/99.

- Three possible damping levels for comfort, sport or extreme sport driving styles in vehicles produced after 09/99.

Driver information due to:

- Vehicle level displayed by indicator lamps and switches.

- Warning messages in multi-function display if vehicle is too low.

Function

The functions of the AIRmatic with ADS control module are divided as follows:

- Signal conditioning

- Function logic component

- Safety circuit

Signal conditioning

The following input signals are processed by the function logic component and used for calculations or to provide information:

- Calculation of body vertical acceleration

- Signal from body acceleration sensors

- Calculation of vehicle speed

- Wheel speed signal

- Speed status signal

- Calculation of longitudinal and lateral acceleration

- Wheel speed signal

- Signal from steering angle sensor

- Calculation of compressor control

- Outside temperature, outside air pressure signal

- Reservoir pressure signal

- Vehicle speed signal

- Vehicle level signal

- Duty cycle

- Calculation for valve control

- Level signal from left front axle, right front axle

- Rear axle level signal

- Calculation for control of main reservoir charge valve

- Level signal from left front axle, right front axle

- Rear axle

- Pressure signal

- Calculation of vehicle level

- Signal from level sensors

- Information signals (control)

- Signal from stop lamp switch

- Signal from comfort and sport switch

- Signal from level control switch

- Signal from door contact switch, trunk, remote control

Function logic component

The conditioned input signals are processed in the logic component and converted into output signals.

- Signal from body acceleration sensors (B24/3, B24/8, B24/9):

- The vertical acceleration of the vehicle is calculated using the signals from the body acceleration sensors.

- Front wheel speed signal, left and right:

- Using the wheel speed signal, the ESP control module calculates

- Vehicle speed

- Longitudinal acceleration

- Vehicle status. A distinction is made between a moving and a stationary vehicle. Incorrect wheel speed signals are also detected.

- Steering angle sensor signal (N49):

- The lateral acceleration of the vehicle is calculated using the steering angle sensor signal and the wheel speed signal.

- Signal from level sensors (B22/8, B22/9, B22/3):

- Both front axle level sensors each supply 2 signals. The sensors detect and transfer the distance between the wheel center and the body at both the left and right-hand side of the vehicle.

- The rear axle level sensor supplies 2 signals. The sensor detects and transfers the distance between the wheel center and the body (average calculated from left and right wheel).

- Brake lamp switch signal (S9/1):

- When the driver presses the brake pedal, a signal is received by the ADS logic component and the damping at all wheels is set to "hard". The pitch motion of the vehicle when braking can therefore be reduced.

- Comfort and sport switch signal (N72/1s3):

- The comfort and sport switch signal informs the system about the selection made by the driver between one comfort-oriented and 2 sporty damping maps. The "comfort" setting maintains the damping within the comfortable range as far as the driving style and road conditions will allow. The "Sport 1" setting makes the damping somewhat "harder". The "Sport 2" setting immediately sets the damping force to "hard". The driver's preferred settings are stored until changed by the driver (even with Ignition OFF).

- Signal from level adjustment switch (N72/1s2):

- The control module uses the signals from the level adjustment switch to determine the driver's preferences for the vehicle level:

- Normal level

- Raised level

- The control module uses the signals from the level adjustment switch to determine the driver's preferences for the vehicle level:

- ADS II

- The control module uses the vertical body acceleration, longitudinal and lateral acceleration of the vehicle and the ground speed to determine the optimum level of damping. 4 different damping forces can be set at each wheel by controlling the damping valves located at each wheel. Phased in as of 09/00, the damping is set to the Sport 1 damping level if the vehicle speed is >160 km/h.

- Level control and adjustment

- The control module uses the setting of the level adjustment switch selected by the driver and the ground speed of the vehicle to control the appropriate level control valves and to set the correct vehicle level according to the vehicle load.

- The AIRmatic system is equipped with a pressure reservoir to keep the level control time as short as possible (e.g. after loading). The reservoir pressure is used only when required in order to prevent filling the reservoir too often. This happens, for example if the vehicle level falls below a critical level when loading the vehicle or if the driver has set the vehicle level to "raised level". Pressure from the reservoir is also used when the vehicle is stationary to minimize noise. With normal control when the vehicle is moving, the spring struts are supplied directly by the air compressor.

- Main reservoir pressure control

- The main control parameters are the pressure in the main reservoir, the outside air pressure and the vehicle speed.

- Compressor control

- The compressor is controlled via a relay. Since the compressor is not designed for continuous operation, the absolute running time and cooling phase are monitored to avoid overloading the compressor.

- Wake-up function

A parked vehicle is "woken up" before the engine is started. That is to say, the AIRmatic with ADS control module receives signals from the door contact switches, the trunk switch and infrared remote control indicating that the driver may soon start the engine and drive the vehicle. The current vehicle level is checked immediately and corrected if required. The vehicle level at the front axle is considered to be critical, for instance, if the full wheel angle can no longer be guaranteed. In this case a message appears on the multifunction display in the instrument cluster to warn the driver: "Stop car too low". If the control module is woken (for example by opening one of the doors), there follows a period of spare time before the driver actually starts the engine during which the vehicle level is corrected. This reduces the waiting time required to correct the vehicle level and the vehicle is ready for driving more promptly. Pressure in the main reservoir is used to raise the stationary vehicle. The compressor is only used if the pressure reservoir is empty. It must be ensured that the battery voltage is sufficient to then start the engine.

- Locking function

If the control module detects that all wheels are unloaded when the vehicle is stationary, the valves of the sprint struts are closed. The vehicle therefore remains at the current level. This is essential, for example, when changing a wheel or during repair work (lifting platform).

Safety circuit

The AIRmatic with ADS control module monitors all the important components of the system after they are switched on and during operation. The safety circuit detects faulty signals from sensors, faults in the control module and in the electric line system. If a fault is detected, the system is switched off and a message is displayed on the multifunction display in the instrument cluster to warn the driver. The damper valves for ADS are no longer controlled and remain set to the "hard" damping level (driving safety level). In addition, a fault code is stored in the control module. The level control is partially switched off depending on the fault that occurred. The system always strives to maintain the selected vehicle level. Moreover, the safety circuit continuously monitors the battery voltage. If the voltage falls below 10.5 V or exceeds 17.5 V, the system is switched off until the voltage returns to the specified range.

Components

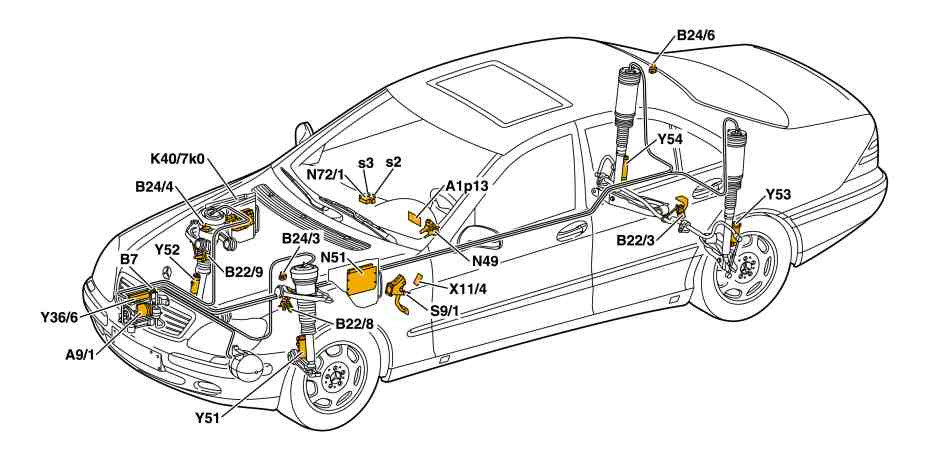

AIRmatic, location of electrical/electronic components:

- A9/1 - AIRmatic compressor unit

- A1p13 - Multifunction display

- B7 - AIRmatic pressure sensor

- B22/3 - Rear axle level sensor

- B22/8 - Left front level sensor

- B22/9 - Right front level sensor

- B24/3 - Left front body acceleration sensor

- B24/4 - Right front body acceleration sensor

- B24/6 - Right rear body acceleration sensor

- K40/7 - Right front fuse and relay module

- kO - AIRmatic compressor relay

- N49 - Steering angle sensor

- N51 - AIRmatic with ADS control module

- N72/1s2 - Level control switch

- N72/1s3 - Comfort and sport switch

- S9/1 - Stop lamp switch

- X11/4 - Data link connector

- Y36/6 - Level control valve unit

- Y51 - Left front axle damping valve unit

- Y52 - Right front axle damping valve unit

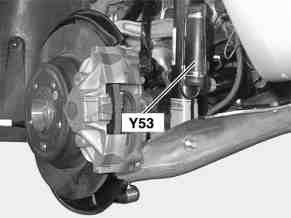

- Y53 - Left rear axle damping valve unit

- Y54 - Right rear axle damping valve unit

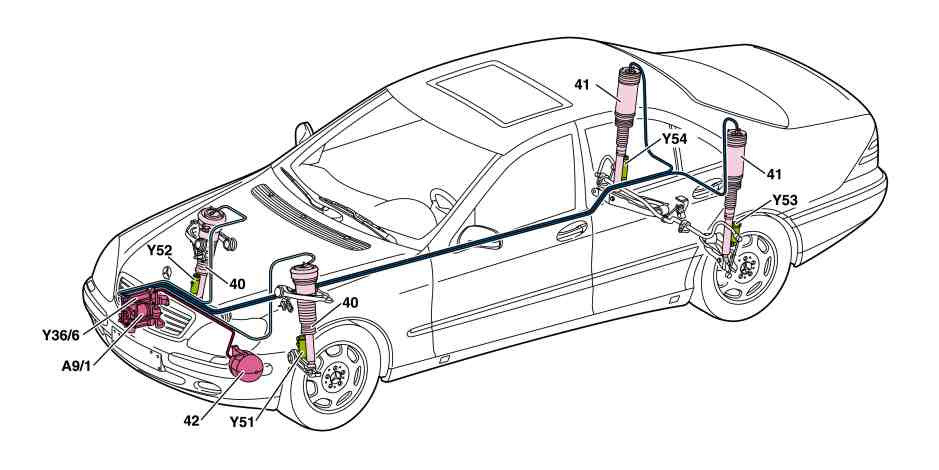

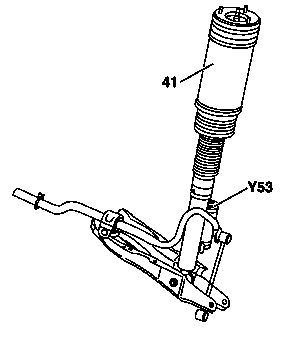

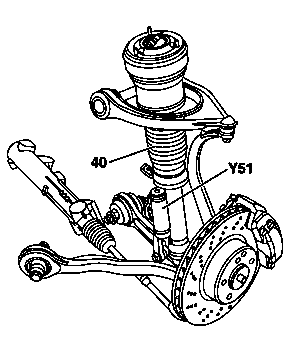

AIRmatic, location of pneumatic/hydraulic components:

- 40 - Front spring strut

- 41 - Rear spring strut

- 42 - AIRmatic central reservoir

- A9/1 - AIRmatic compressor unit

- Y36/6 - Level control valve unit

- Y51 - Left front axle damping valve unit

- Y52 - Right front axle damping valve unit

- Y53 - Left rear axle damping valve unit

- Y54 - Right rear axle damping valve unit

Comfort and sport switch (N72/1s3)

This switch controls Adaptive Damping System (ADS).

The switch with the indicator lamps is located in the upper part of the center console.

The ADS automatically selects the optimum damping for the respective driving conditions. At the same time the suspension is set to either sporty or regular.

The suspension tuning is set according to:

- Your driving style

- Road surface conditions

- Your choice of suspension style, "sport" or "convenience", which you select using the damping switch.

The following suspension styles are available:

- "Convenience" - both indicator lamps (1) are off.

- "Sports 1" - one indicator lamp (1) is on.

- "Sports 2" - both indicator lamps (1) are on.

The selected suspension style is stored in memory, even after the SmartKey is removed from the starter switch.

Level control switch (N72/1s2)

This switch controls Airmatic Level control system.

The following vehicle level settings can be selected when the vehicle is stationary:

- "Normal" - for driving on normal roads. The indicator lamp (1) is off.

- "Raised" - for driving on rough roads or with snow chains. The indicator lamp (1) is on.

Select the "Raised" level setting only when required by current driving conditions. Otherwise the fuel consumption may increase and handling may be impaired.

The vehicle chassis ride height is raised or lowered according to the selected level setting and to the vehicle speed (these height adjustments are so small that you may not notice any change):

- With increasing speed, ride height is reduced by up to approximately 3/4 in (20 mm).

- With decreasing speed, the ride height is again raised to the selected vehicle level.

The selected vehicle level setting remains stored in memory even if the engine is turned off and restarted. However, the vehicle lowers to regular level when you exceed a speed of 75 mph (120 km/h) or maintain a speed of between 50 mph (80 km/h) and 75 mph (120 km/h) for more than 5 minutes.

This can be used to raise the vehicle level by 25 mm (20 mm USA). The raised level switch position is indicated by the red indicator lamp (1) in the switch. In addition, the multifunction display in the instrument cluster displays: "AIRMATIC VEHICLE RISING".

As long as the multifunction display in the instrument cluster shows the message: "AIRMATIC VEHICLE RISING", the desired vehicle level has not yet been reached. If the raising of the vehicle is cancelled due to the driving speed, the instrument cluster displays the following message for approx. 10s: "AIRMATIC LEVEL SETTING CANCELLED". If the vehicle is raised several times in quick succession, it may happen that the air compressor shuts down temporarily in order to prevent an overload. The raising sequence will then take an unusually long time.

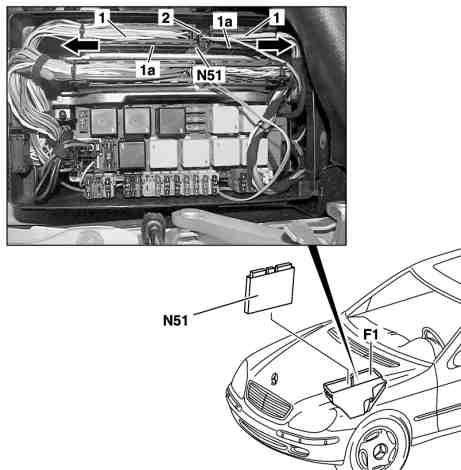

AIRmatic with ADS control module (N51)

AIRmatic with ADS control module, task: To execute all control functions of ADS and AIRmatic. Air suspension control unit is located in left fuse box.

Input Functions

The AIRmatic control module receives input signals over CAN Bus from the following components:

- ESP control module

- Engine control module

- Transmission control module

- Instrument cluster

- Steering angle sensor

- ADS comfort and sport switch

- Level adjustment switch

- Three body accelerometers

- Two front axle level sensors

- One rear axle level sensor

- One Airmatic pressure sensor

Output Functions - Airmatic

The Airmatic input signals are converted in the Airmatic control module to output signals for the following components:

- Four Level control valves

- One main reservoir charge valve

- Four ADS damper valves

- Multi-function display

- Switch indicator lamps

- Air compressor

|

|

Level control valve unit (Y36/6)

Damping valve unit (Y51, Y52, Y53, Y54)

Damping valve, task: adapts the damping force to the driving style and road condition.

|

|

|

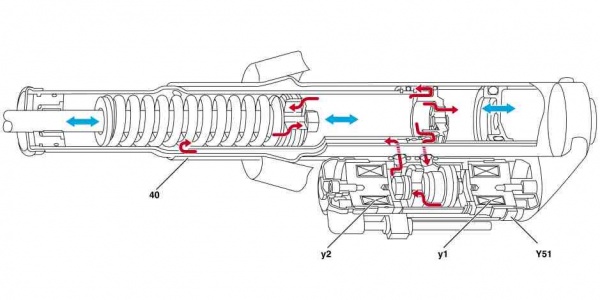

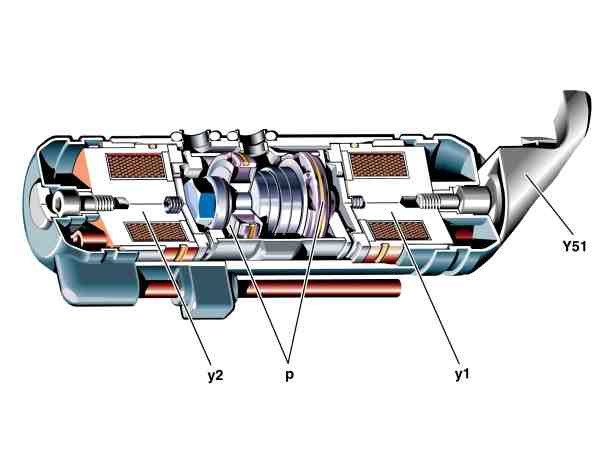

Adaptive damping system (ADS II), function

The damping force is regulated in damping valves (Y51, Y52, Y53, Y54). Each wheel has one damping valve installed between the upper and lower chambers of the single-pipe gas-filled shock absorber. Each damping valve contains two electromagnetic valves (y1, y2), allowing four different damping force settings according to how they are actuated via the AIRmatic with ADS control module.

The extremely short adjusting time (milliseconds) means that the optimum damping force setting is available almost immediately if sudden changes in the vehicle level are required, such as during an obstacle-avoidance maneuver.

Design

- Y51 - left front axle damping valve

- y1 - front axle solenoid valve 1

- y2 - front axle solenoid valve 2

- p - piston reed valve pack

The damping valve (Y51, Y52, Y53, Y54) consists of a casing and 2-piston reed valve packs (p). Located above are the spring-loaded solenoid valve pistons and the solenoids. The valve pistons and solenoids form the solenoid valve units (y1, y2).

If the solenoid valve coils (y1, y2) are not actuated, the spring-loaded solenoid valve pistons (y1, y2) keep the holes directly below them closed. Oil is displaced via the reed valve packs (p) and the oil duct located diagonally opposite in the casing.

If the solenoid valve coil (y1) is actuated, for example, the solenoid valve piston (y1) allows the hole to open and the oil can flow over this hole. Only a small amount of oil is displaced via the piston reed valve pack (p). The damping force levels are achieved by means of the differently positioned reed valve packs and controlling the solenoid valves.

Function

- 40 - Front axle suspension strut

- Y51 - Damping valve

- y1 - Solenoid valve 1

- y2 - Solenoid valve 2

- a - Bypass valve, hard compression

- b - Bypass valve, soft rebound

- c - Bypass valve, hard rebound

- d - Bypass valve, soft compression

- f - Operating piston

- m - Dividing piston

- o - Pressure chamber

- r - Bottom valve

The ADS suspension control module is used to achieve four different damping force settings:

- Damping force setting 1

- For comfortable rolling with small sprung mass vibrations and low longitudinal and lateral acceleration. With this damping force setting both solenoid valves y1 and y2 are open so that most of the oil flows parallel to the hard rebound and compression of the operating piston via the softer reed valves at the solenoid valves. The comfort rebound and compression setting is therefore achieved.

- Damping force setting 2

- The reed valves at the valve piston generate a firmer setting. If the vehicle is lowered, solenoid valve y2 is opened and solenoid valve y1 is closed. The reed valves (a = hard compression and b = soft rebound) at solenoid valve y1 generate a hard compression and a soft rebound.

- Damping force setting 3

- The reed valves at the valve piston generate an even firmer setting. If the vehicle is raised, solenoid valve y1 is opened and solenoid valve y2 is closed. The reed valves (c = hard rebound and b = soft compression) at solenoid valve y2 generate a hard rebound and a soft compression.

- Damping force setting 4 (driving safety setting)

- For increased driving safety with high longitudinal and lateral vehicle acceleration. Both solenoid valves y1 and y2 are closed. The reed valves (a = hard compression and c = hard rebound) generate a hard compression and rebound. All the oil flows via the hard rebound and compression of the operating piston. This damping force setting is also selected if the ADS system fails and the ADS suspension warning light (A1e27) comes on in the instrument cluster.

| Damping force setting | Damping valves (Y51-Y54) | Valve control | ||

|---|---|---|---|---|

| Rebound | Compression | Solenoid valve (y1) | Solenoid valve (y2) | |

| 1 | Comfort | Comfort | Open | Open |

| 2 | Soft | Hard | Closed | Open |

| 3 | Hard | Soft | Open | Closed |

| 4 | Hard | Hard | Closed | Closed |

Multifunction display (A1p13)

Various messages concerning the AIRmatic and ADS are shown in the multifunction display in the instrument cluster and in the comfort and sport and level adjustment switches.

AIRMATIC VISIT WORKSHOP!

In the event of electrical faults in the AIRmatic or ADS system, the following message appears on the multifunction display in the instrument cluster: "AIRMATIC VISIT WORKSHOP!". The fault is stored in the ADS suspension control module and can be read out using the diagnosis tool.

Limp-home function A malfunction in the adaptive damping system causes the ADS to shut down. The suspension is switched to the hardest setting. In the event of a fault in the suspension system or in the level adjustment system, the vehicle attempts to maintain the set level. Manual and automatic level adjustments are no longer possible.

AIRMATIC STOP, CAR TOO LOW!

If the vehicle level at the front axle is more than 50 mm (60 mm USA), or at the rear axle more than 60 mm (70 mm USA) below the normal level, the multifunction display in the instrument cluster displays the warning: "AIRMATIC STOP, CAR TOO LOW!". The display disappears again when the level has risen back to 48 mm or 58 mm (58 mm or 68 mm USA) respectively below the normal level.

Emergency Procedure - Airmatic

Emergency procedure refer to: http://www.benzworld.org/forums/w220-s-class/1547183-how-fix-w220-airmatic-strut-6-a.html

Issues - Airmatic

With thanks and acknowledgement to the authors with some editorial licence.

Issues by eric242340 - Airmatic

Now, the rear suspension, in my opinion, almost never develops air leaks. The real problems come with the following:

- 1. Compressor failure or partial failure.

- 2. Valve block on top of compressor failure (very common).

- 3. Valve failure on rear suspension strut (often indicated by DAS) but wrongly.

- 4. Air leak on front suspension tops (for which there is a modification).

- If it is 1 then new compressor.

- If it is 2 then new valve block.

- If it is 3 then new strut (but uncommon).

- If it is 4 then do the modification.

But however you look at this, if the garage does not have Star Diagnostics and a Mechanic who can interpret the values both in sensor voltage and other tests then don't waste your time and money.

With thanks to BenzWorld Member eric242340 refer to: http://www.benzworld.org/forums/w220-s-class/1329314-s-class-airmatic-woes-yes-again.html

Issues by danielsand - Airmatic

The Airmatic is NOT terribly complicated system. Don't be scared of it, and go slow and systematic in troubleshooting it. How does it work? Simple. The electricity is supplied to the pump via the (hopefully!) Hella relay (passenger side fuse box - US config), the relay is the first one next to the three 40 amp fuses. First fuse next to the relay is a smog pump fuse (forget about it), and the middle one is #32 that protects the Airmatic circuit. Check that first. (and yank both pieces OUT BEFORE you start working on Airmatic!!)

Once the relay sends the juice to the pump, the pump comes alive. The air comes in through the black hose (that has the filter in-line), and then the air is supplied to the valve (nothing mysterious there, just a "crossover" valve that directs the air to the struts that need it, based on the input from the sensors). If the pump is working, but not sucking, either the filter is blocked (unlikely), or the hose is kinked, damaged or obstructed.

If all connections of the white PVC lines on the valve (and the main line that goes from the pump to the valve) are holding air, the car HAS TO rise. If it doesn't, there is a leak somewhere that is not easy to detect. Once the air is distributed by the valve to the struts, it goes to the top of the struts and inflates the air bags inside the struts. If the pump is working, and there is no air reaching the valve, the main PVC line is kinked, broken, cracked, or obstructed.

If the air (with correct pressure) is reaching the valve, but it's not supplied to the struts, the valve has a problem (electrical connections damaged, dirty, not connected, or valve itself going bad). If the valve is doing its job, and the struts are not being inflated, then the struts have a LEAK (a big one!).

Now, when you removed the Airmatic pump, how did you lift the car, and more importantly, how did you LOWER it back down? If you read EVERYTHING about Airmatic, you will find out that overextending the strut can cause the leak on the strut under the bellows, and more importantly, once lowered down, you HAVE TO inflate the struts BEFORE the full weight of the car is on deflated struts!

When I replaced my pump, I used TWO jacks. One to lift the body, and one under the swingarm to lift the wheel without over extending the strut (I lifted only the passenger side). Passenger side strut was never overextended, and after the replacement was done, I lowered the car until the wheel touched the ground (still on the jacks, without the full weight of the car on the wheel), and THEN I engaged the pump, and let it run for few minutes. I didn't have to, because my strut was not completely empty (valve prevents the complete loss of air), but I played it safe.

Bottom line, the Airmatic bellows never became detached, air never escaped, and after the pump was bolted and operated, I sprayed soapy water on all PVC connections, and detected no leaks.

So, read the BenzWorld Encyclopedia and learn about all components of the Airmatic system, and go slow. Once you learn how it all operates, and what each part of the system is supposed to do, you will find the fault, no doubt. Good luck!

With thanks to BenzWorld Member danielsand refer to: http://www.benzworld.org/forums/w220-s-class/1557414-2001-s430-airmatic-not-rising-please-3.html

Issues by nicedeals.co.uk - Airmatic

If the air suspension on your M-B S Class has dropped on all four wheels and the diagnostic test is pointing towards an Airmatic pump fault, you will most likely need to replace it. The airmatic pump on the W220 model is located under the driver side front wing splashguard. Remove the alloy wheel and remove the nuts and clips holding the splashguard in place.

If the drop is limited to one side only, the fault will most likely be limited to that particular shock absorber air bellow unit.

http://www.nicedeals.co.uk/car/diy/8-mercedes/2509-mercedes-w220-s-class-airmatic-pump-replacement

Level Control and Notes - Airmatic

Edit required.

http://www.benzworld.org/forums/w220-s-class/1656870-airmatic-rear-end-drooping-intermittently.html

http://danirangelov.blogspot.com/2013/09/mercedes-w220-s-class-airmatic-level.html

http://www.benzworld.org/forums/w220-s-class/1467695-airmatic-strut-epoxy-fix-3.html

DIY Procedures - Airmatic

Edit required.

DIY Diagnosis - Airmatic

Diagnosis with soap water. http://www.benzworld.org/forums/w220-s-class/2242706-airmatic-winter-problem-2.html

http://forums.mercedesclub.org.uk/showthread.php?t=110643

C1324-001 Fault in component Y53y1 (Left rear solenoid valve 1) in assembly Y53 (left rear axle damping valve unit)

C1325-001 Fault in component Y53y2 (Left rear solenoid valve 2) in assembly Y53 (left rear axle damping valve unit)

DIY Valve - Airmatic

http://www.benzworld.org/forums/w220-s-class/1656870-airmatic-rear-end-drooping-intermittently.html

DIY Pump - Airmatic

DIY Relay - Airmatic

DIY ECU - Airmatic

DIY Height Sensors - Airmatic

DIY Struts - Airmatic

Replacements - Airmatic

Arnott Rebuilds

Arnott rebuilts cost $575 but they only install new rubber air bladders and not the shock piston seals or gas charge. But Arnott rebuilt units DO allow you to maintain the selective electronic damping, ie the button on the center dash that firms up or softens the ride.

Arnott New

Arnott NEW units cost $624. BUT with all new units you lose the electronic damping. While the new Arnott units allow you to plug in the original wire harness from the car. It simply fools the computer to thinking the selective damping is functioning. In reality it's not and the shock has mechanical damping instead.

Bilstein OE

If Bilstein is indeed the OEM manufacturer for M-B and a brand new strut from Bilstein costing $700 would come with entirely new components you wouldn't lose any original functionality or comfort.

Replacement Tutorials - Airmatic

http://www.bilsteinus.com/fileadmin/user_upload/user_upload_us/pdfs/E4-WM5-Y328A00_01.pdf (EN/DE)

http://info.bilsteinus.com/mercedes/ (videos)