Headlights

Introduction - Headlight Systems

HID Xenon Systems

HID stands for High-Intensity Discharge. Xenon is the type of gas inside the bulb. Xenon bulbs can produce a brighter, whiter light than a halogen car, and tend to have a longer lifespan. The bulb works in a different way to a halogen. Instead of a filament heating up and glowing, xenon headlights use electrodes to discharge the gas inside the bulb. This produces the light you see on the road. In order for xenon bulbs to work they require electronic ballasts, and ignitors to generate the high voltages required to discharge the gas.

HID xenon headlight systems come in two different types, xenon and bi-xenon.

HID Xenon Headlight Systems

HID xenon headlight systems use two separate bulbs for the high and low beam illumination. The main high beam system uses xenon bulbs, electronic ballasts, and ignitors. A separate conventional halogen bulb is also fitted for low beam.

HID Bi-xenon Headlight Systems

HID bi-xenon headlight systems use one bulb for both high and low beam illumination. To achieve low and high beam illumination with a single HID bi-xenon bulb, it is used in conjunction with a lens projector which has a solenoid/motor that is attached to a cutoff plate or shield. When the 'high beams' are activated a signal is sent to the solenoid and the motor will lower the cutoff plate/shield allowing more light to shine above the shield; hence high beams.

A pair of separate conventional halogen globes are also used to provide instant illumination and a support and backup to the bi-xenon system.

Halogen Systems

Halogen headlight systems use separate low beam and high beam bulbs in different locations. Sometimes dual filament bulbs are used to produce both high and low beams in one bulb. Halogen bulbs are cheap to manufacture, plus they’re very simple to replace. Inside the bulb is a filament made out of tungsten and halogen gas. The bulb lights up when electricity reaches the filament, heating up the tungsten which begins to glow. Most halogen headlamps produce a colour temperature between approximately 3200K and 5000K. The higher the Kelvin rating, the cooler and bluer the light will be.

Be careful when replacing a halogen bulb. It is popular to replace a standard halogen with an aftermarket bulb in order to achieve a white/blue tint. After market globes usually achieve this by applying a blue coating to the bulb, which the light then shines through. However, this can compromise the light output of the bulb as the blue coating can obscure the amount of light that can penetrate it. Some after market halogens are now turning to a clever xenon and halogen gas mix, which helps to produce a whiter light than the halogen gas can on its own. Be sure to use the same wattage as the original.

LED Systems

Modern LED bulbs are proving to be very popular as they can produce an extremely white light. They are much more efficient, due to their long lifetime and the low wattage they require to work. LED bulbs were never fitted as original equipment for W220 high or low beams. Fitting them to W220s as after market equipment poses problems due to the sophisticated bulb monitoring system built into the W220. Due to their low current draw they will be detected as blown globes and may even flash instead of producing constant light. They also need to be cooled from the back of the bulb and may require a redesign of the lens assembly.

Description

W220's were built with two completely different main headlight systems, namely;

- High Intensity Discharge (HID) systems using bi-xenon bulbs with electronic ballasts, ignitors and motorised lens projectors for both high beam and low beam, and

- Halogen systems using conventional bulbs.

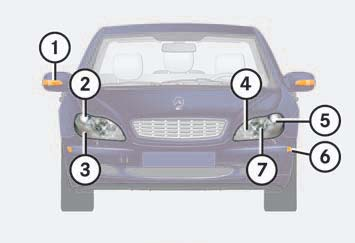

Facelift

Pre-facelift

Locations

HID Headlight Locations

Halogen Headlight Locations

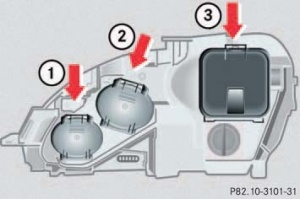

Replacing bulbs for front lamps

|

|

|

|

|

|

|

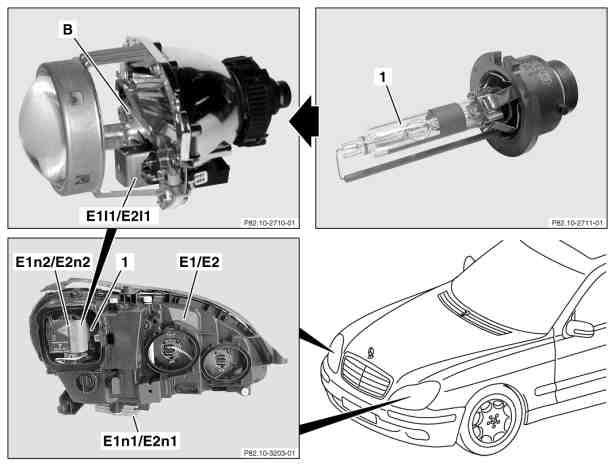

Bi-Xenon headlamp

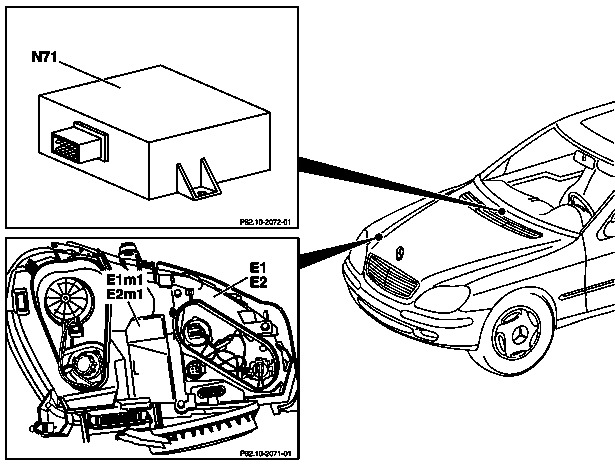

The headlamps in W220 facelift differ from the previous xenon headlamps on account of their entirely new lighting technology development, which the xenon light uses for low and high beam lights. The new lighting technology, known as Bi-Xenon, is located in the outer headlamps.

When the low beam lamps are switched on the xenon headlamp control module (E1n1, E2n1) activates the xenon headlamp control module and ignition module (E1n2, E2n2) via the control voltage within a few milliseconds. A high-voltage surge from the ignition device ignites the xenon lamps, and in doing so an electric arc is formed between the electrodes. If an electric arc of sufficient stability is detected the control circuit switches the control modules (E1n1, E2n1) over to power-limiting mode.

With the bi-xenon headlamps, the light generated in the previous manner in a gas discharge lamp (D2S lamp) travels directly through the optical system without being reflected.

A voltage converter generates the required voltage for the reliable function of the xenon headlamp.

For technical reasons the xenon lamp has a timed startup characteristic. After switch on, 50 % of the luminosity is reached within 1 to 2 seconds and full luminosity is achieved after another approx. 30 seconds.

The entire luminous flux is made available for the high-beam lights. When switching over to low-beam operation a screen is moved into position between the gas-discharge lamp and the lens, which covers up the luminous flux directed into the distance and thus helps to prevent oncoming traffic from being dazzled.

The shield (B) is controlled electro-mechanically by the solenoids in the right and left high beams (E1l1, E2l1).

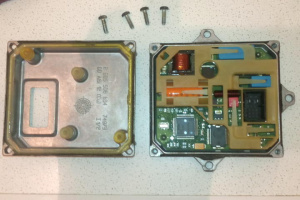

Xenon headlamp control module (ballast)

|

|

|

The xenon headlamp control module (E1n1, E2n1) activates the xenon headlamp control module and ignition module (E1n2, E2n2) via the control voltage and regulates the voltage supply to the xenon headlamps.

The same control module is used on both sides. The MB part number is not identified on the part, however, the control module is ECU and MB part number can be obtained by establishing connection to the headlamp control module using DAS.

Other ballasts (e.g., 1307329072/A2038202526 from C-class) will also light up the bulb, but may report headlamp range adjustment errors (tested in vehicle without ABC).

| Part No. | Notes |

|---|---|

| A2208203785 | [614/618] From 30/09/2002, replaced by A2208207085 |

| A2208207085 | [614/618] From 30/09/2002 |

| A2208203885 | [614/618 +487] From 30/09/2002, replaced by A2208207185 |

| A2208207185 | [614/618 +487] From 30/09/2002 |

| A2308201926 | [614/494 +-487] From 30/09/2002, replaced by A2308208426 |

| A2308208426 | [614/494 +-487] From 30/09/2002 |

Xenon headlamp ignition unit

The xenon headlamp ignition device, (E1n2, E2n2) ignites the xenon lamps by means of a high-voltage surge.

Headlamp range control (HRC)

Electric headlamp range adjustment is required by law for vehicles with xenon headlamps to prevent dazzling oncoming traffic. The headlamp range adjustment automatically keeps the inclination angle of the low beams within the legally defined limit regardless of how the vehicle is loaded.

The headlamp range adjustment control module utilizes the signals from the level sensors on the front and rear axles for control and adjustment of the low beams. The pneumatic suspension control module processes the signals from the level sensors and transfers these to the headlamp range adjustment control module via the data bus (CAN). The headlamp range adjustment control module compares the signals with the headlamp adjustment and, if necessary actuates the headlamp range adjustment motors in the headlamps to correct the angle of inclination.

In addition to the signals from the level sensors the headlamp range adjustment control module also processes a wheel speed signal proportional to the vehicle speed transferred on the data bus from the ASR/ESP control module. Evaluation of this wheel speed signal indicates to the headlamp range adjustment control module whether the vehicle is driving at constant speed, accelerating or decelerating. At constant vehicle speed the headlamp range adjustment operates in the "static mode" with minimum headlamp motor adjustment speed. During acceleration or deceleration the "dynamic mode" with high adjustment speed is actuated.

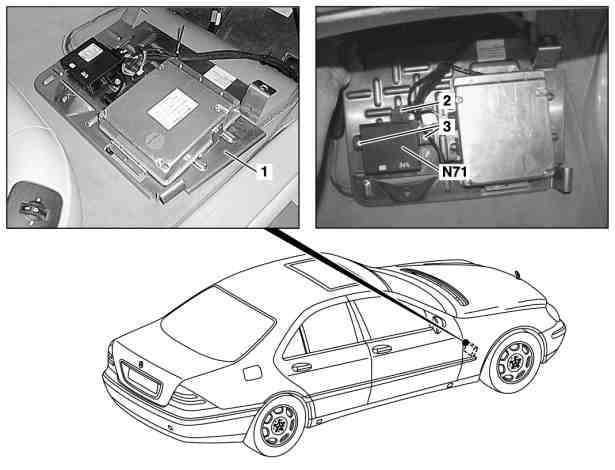

Headlamp range adjustment control module

|

|

The control module evaluates the signals from the pneumatic suspension control modules and ABS/ASP control modules as well as the headlamp range adjustment motors. It actuates the headlamp range adjustment motors depending on the vehicle load, vehicle status and position of the headlamps.

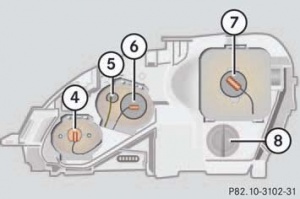

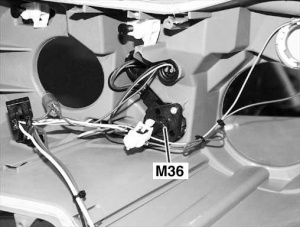

Headlamp range adjustment motors

The headlamp range adjustment motors in the left and right headlamps adjust the inclination angle of the reflectors depending on the actuation by the control module. The position of the reflectors is indicated to the control module by potentiometers in the motors.

|

|

Both headlamps (left and right) contain headlamp range adjustment motor part number A1408201908.

|

|

|

| Error Code | Generated By | Description |

|---|---|---|

| B1480 | HRA - Headlamp rangeadjustment | Component M36 (Left headlamp range adjustment motor) has Short circuit or open circuit |

| B1481 | HRA - Headlamp rangeadjustment | Component M37 (Right headlamp range adjustment motor) has Short circuit or open circuit. |

For the last two error codes a dead motor is rarely a cause. Disconnected plug is the most common cause.

Washer

Washer (~EUR 40) for bi-xenon headlamps is A2208260791 (left) and A2208260891 (right). Washer from the pre-facelift headlamps will not fit. After years of use the rubber becomes fragile and breaks easily. From the practical perspective there does not seem to be any function of this washer, because the water is prevented from entering the headlamp with the sealing used to attach the lens to the headlamp.

|

|

Wiring

H7 Upgrade

PHIPILS Diamondvision

PHILIPS offers Diamond Vision 5000K white light H7 bulbs (~30 EUR/pair).

|

|