DIY Transmission Service W220 WITH TC Drain Plug

Back to WIS 27.00 Transmission - General

DIY Transmission Service W220 WITH a TC Drain Plug

Initial Preparation

Shift Transmission into Neutral and switch off ignition.

Use ramps, jacks, jackstands, etc to get the car up to a comfortable working height.

The transmission pan must be level in both the longitudinal and transverse axes. The easiest way to verify level is by using a magnetic level on the transmission pan.

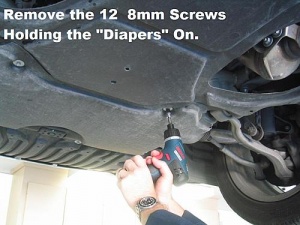

Remove the engine under splash shields and the rear engine cover by removing the 8mm bolts. Set the bolts and shields off to the side.

Layout plastic drop sheets under trans pan and under trans cooler intermediate connector.

Find suitable containers for catching and storing at least 10L of waste fluid.

Have a pen and paper ready to record quantities of all removed old fluid and all replaced new fluid. Record results on print out of the suggested Table of Fluid Quantities below.

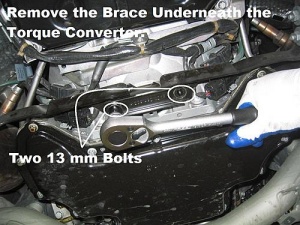

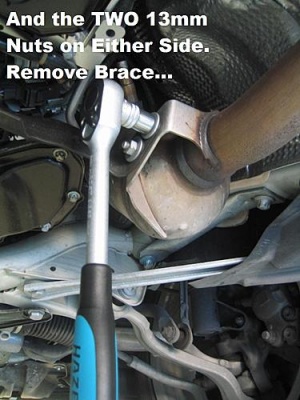

Remove the Brace Underneath the Torque Converter

Remove the black rubber plug from the transmission bell housing forward of the pan. This is the access hole for the torque converter.

Now unplug the 2 electrical connectors running across the front part of the transmission pan. Then unclip the connectors from the bracket holding them in place, and tuck the wiring and connectors up out of the way.

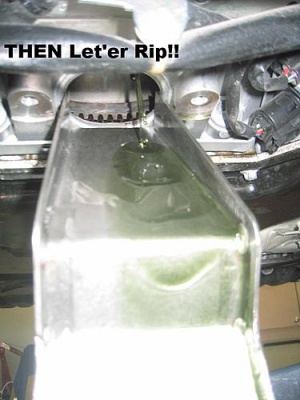

Drain Torque Converter Fluid (4L)

Carefully collect all Transmission Fluid drained (both T/C and Pan) to be measured later.

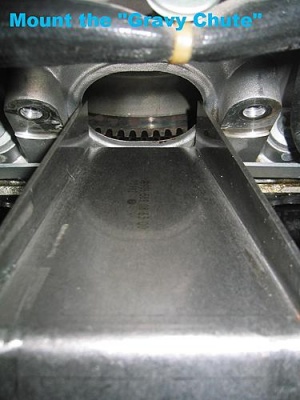

Fashion a Shield for Draining Torque Converter

The problem with draining the torque converter is that the drain plug is at an angle in relation to the access hole. So, when you pull the drain plug, the ATF drips down into the bell housing. There is little to no clearance to get rags in there to clean it up.

If any fluid gets trapped in the bell housing while draining the torque converter it is very difficult to clean up afterwards and can appear as if there is a leak later on. Fashioning a simple shield out of Aluminium will keep fluid from running down the bell housing.

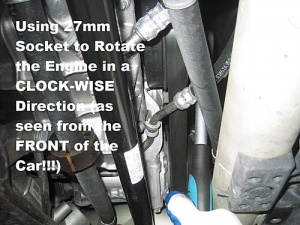

Using a 27mm socket and breaker bar on the engine crankshaft pulley bolt, turn the engine little by little, until you can see the torque converter drain plug in the center of the access hole.

Find torque converter drain bolt (Either M8 or M10 thread)

Loosen torque converter drain bolt (4mm Allen or Hex)

Mount chute.

Carefully collect all Transmission Fluid drained (both T/C and Pan) to be measured later.

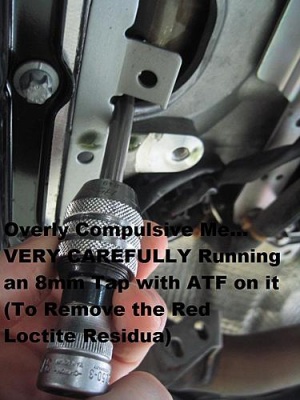

Remove residual Loctite material from torque converter drain plug thread.

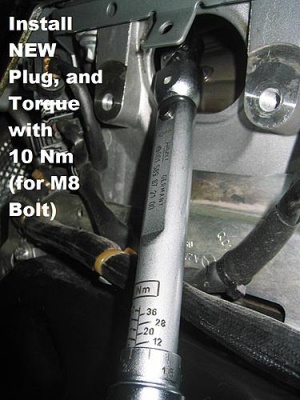

Install New Torque Converter Drain Plug and Washer

Install a NEW torque converter drain plug and torque to 10Nm if 8mm and 15Nm if 10mm.

Install rubber plug back in torque converter access hole.

Remove Wiring Brace

Remove the wiring brace for the O2 sensors running across the front part of the transmission pan. Then unclip the connectors from the bracket holding them in place, and tuck the wiring and connectors up out of the way.

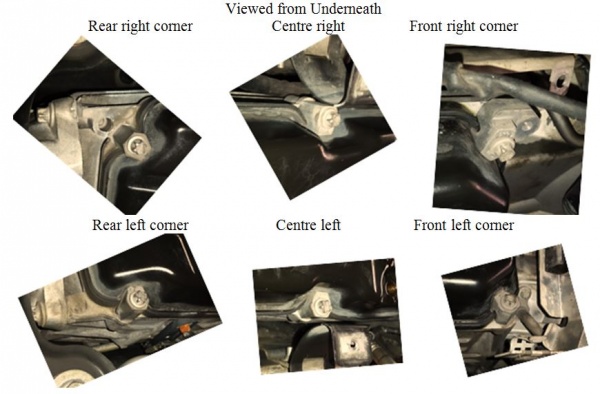

Record Location of Pan Bolts and Sprags

TAKE A PHOTO and then carefully check the position and location of the pan bolts and sprags before removing them. (Front right corner has odd sprag with threaded bolt hole.)

Drain Transmission Fluid

Place a waste container under the transmission drain plug, and remove the drain plug with a 6mm Hex socket and ratchet. Around a litre or so of fluid will drain from the pan. Note the 6mm Hex drain is easy to damage unless a steady upward force is applied during removal.

Carefully collect all Transmission Fluid drained to be measured later.

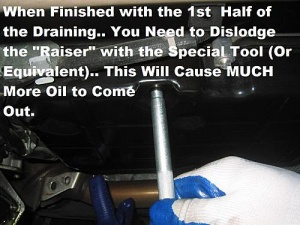

Using the MB drift or other suitable tool, pry the transmission overflow pipe off its seat in the pan by inserting the drift through the drain plug hole in the transmission pan. About another 2 - 3 litres of fluid will drain out. The overflow pipe doesn’t need to come completely off its seat. Just dislodged enough so the rest of the transmission fluid will drain out.

Carefully collect all Transmission Fluid drained to be measured later.

Temporarily Reinstall the Old Drain Pan Plug Finger Tight to Stop Drips

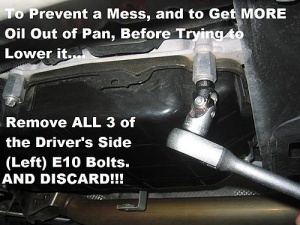

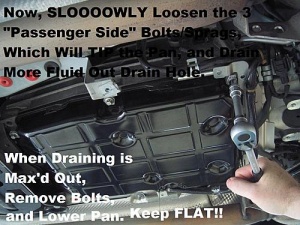

Remove the three E10 torx bolts and sprags holding on the transmission oil pan on the right side. Loosen the three E10 torx bolts and sprags on the left side. Carefully pull down on a corner of the pan to release the pan from the transmission. Keep pan level.

Carefully collect all Transmission Fluid drained to be measured later.

Remove the Transmission Filter

Grab the transmission filter and pull straight down to remove from transmission.

Carefully collect all Transmission Fluid drained to be measured later.

Record the quantity of fluid after the pan/filter removal

Record the quantity of fluid collected during the pan and filter removal process.

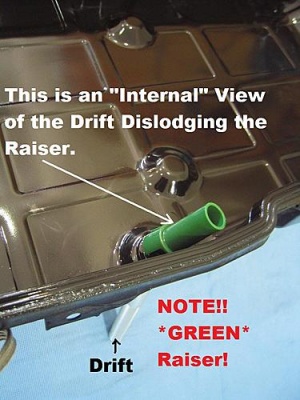

Remove white overflow pipe and magnets from inside trans pan

TAKE A PHOTO and then remove the white standoff pipe and the two magnets that sit on the bevelled edge of the trans pan.

Clean Transmission Pan and Mating Surfaces

Remove and discard the transmission pan gasket.

Now the most important part, cleaning. Thoroughly clean the transmission pan, magnets, sprags, and pan mounting surface of the transmission. The sealing surfaces of the pan and transmission housing must be absolutely free of any contaminates. Use a quick flashing solvent to clean everything, like Brake Parts Cleaner, Isopropyl Alcohol, Denatured Alcohol, etc. For good measure if you have compressed air, blow off the pan to make sure no lint, etc is left behind.

I cleaned the NEW pan, NEW gasket, and transmission housing with a new microfiber cloth. Tried the leather chamois, and it left a bunch of lint behind. So, after cleaning with the microfiber I blew everything off with compressed air.

Install New Transmission Filter

Install a new transmission filter. Make sure the filter has a new o-ring installed. To install, just position filter with standoff pointing up, and push into place.

Reinstall Cleaned Transmission Pan

Note need to replace the cleaned magnets back into the bevelled side of the pan in the same way you removed them.

Place a NEW overflow tube onto the inside of the pan above the drain plug hole. Be certain the tube firmly snaps into place and the bottom of it is sitting flush on the pan. Notice a Definite CLICK.

Place a NEW transmission pan gasket onto the pan. CAUTION: Do not apply any sealant or sealing compound to transmission oil pan or transmission housing.

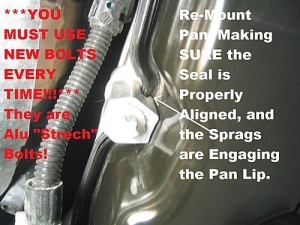

Have the six NEW transmission bolts and the sprags ready, then hold the transmission pan in place, while inserting bolts through each sprag and hand tighten the bolts.

I then proceeded to bolt up the pan. Here is where I think I screwed up last time. There were 2 sprags, that weren't quite touching the transmission housing on the outside edge before I pulled the pan. This time I was VERY careful in making sure all the sprags were correctly seated on the pan. I did this by putting the two centre sprags and bolts on loose enough just to hold the pan in place. Then I had to wiggle and push the pan toward the rear of the car to get the pan and sprags to seat correctly. The rear of the pan gasket touches the bracket for the transmission mount, and the gasket needs to be compressed slightly against it. I noticed this the first time I put the pan up, but didn't push the pan toward the rear while putting the sprags and bolts in, and remember the front two were a little difficult to hand tighten the bolts. By pushing the pan toward the rear while hand tightening the bolts seemed to work much better this time.

Can use automotive high tensile M6 x 1.0 x 40 45mm hex key bolts torqued to 12Nm (8.9ft-lbf) as a temporary measure.

Once there are no leaks then the M6 bolts can be replaced with the genuine MB one-use ones.

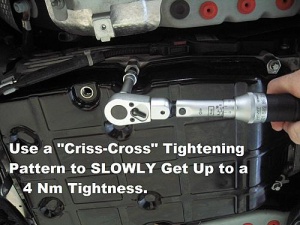

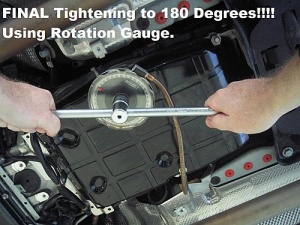

Now using a torque wrench tighten the six bolts to 4Nm. Once all are tightened to 4Nm (3 ft-lbf), then tighten each bolt an additional 180°.

Reinstall the electrical connectors

Reinstall the electrical connectors back into place on the bracket in front of the trans pan and reconnect them.

Record Volume of Fluid Drained from Pan

Record the volume of fluid drained from pan.

Calculate the total quantity of fluid drained so far

Calculate the total quantity of fluid obtained from the system so far using the printed record table. Take into account that a small quantity may have been put back in during the initial flushing of the return line.

Expect about 8L (8.5 US Quarts) total.

Initial Filling Transmission with Fluid

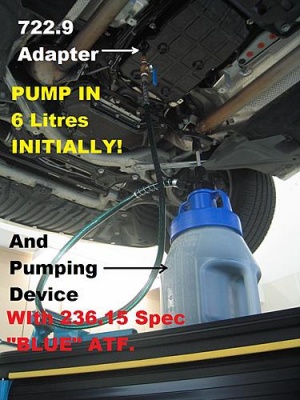

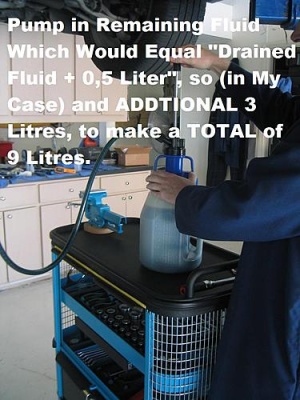

Fill the Assenmacher Refill Container with new fluid to the quantity removed from the calculation above.

Attach the Assenmacher Refill adapter (ATF 129) shut-off valve and hose to the pan.

Technique for Filling

The most important part is to always pump fluid in and try to pump as little air in the transmission as possible.

If necessary search for the latest up to date MB WIS document AR27.00-P-0270SYZ on filling the transmission and checking fluid level.

Pump in initial quantity of fluid into the transmission pan.

Shut off valve and leave the adapter, pump, and bottle in place. (The trans should now have its original quantity of fluid but as a mixture of new fluid in pan and old fluid in torque converter.)

Setting Transmission Fluid Level

Have new pan drain plug and washer ready for final installation. The seal ring for the drain plug must be replaced. The ring is a 12mm x 16mm x 1.5mm ring. Any standard copper 12mm sealing ring can be used. These can be had at most hardware stores. If you plan on doing a few changes, pick up the 25pack from McMaster Carr.

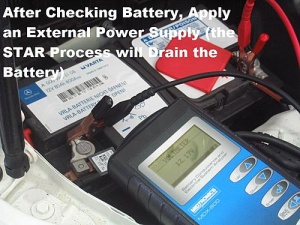

Connect charger to car battery or charging point

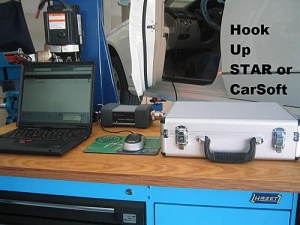

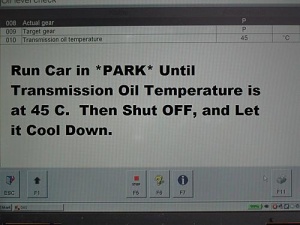

Activate STAR SDS and navigate to monitor transmission fluid temperature. (ECU/Electronic transmission control (722.9 7G-Tronic)/Actual values/Oil level check/F2/010 Transmission oil temperature.)

Restart car engine and allow to idle in Park.

Shut off engine when fluid reaches 45°C.

Pump in remaining fluid to make a total of 9.5L. Record any fluid quantity changes.

Leave filler adapter in place.

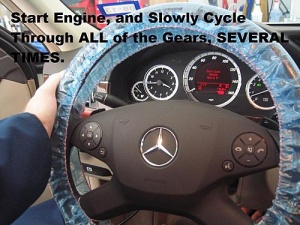

Start the engine. DO NOT SHUT OFF THE ENGINE UNTIL INSTRUCTED TO BELOW, ie only when fluid level is correct as below.

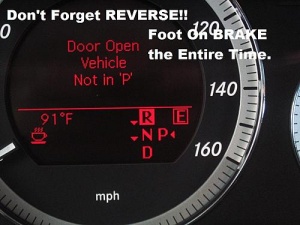

With the engine idling and your foot on the brake, shift through "P-R-N-D" several times.

Allow engine to idle in selector lever position "P". ie keep the engine running.

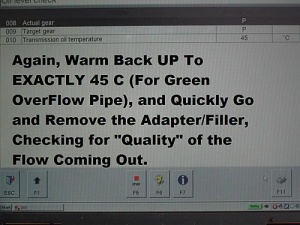

Call up the transmission fluid temperature Transmission oil temperature using STAR DIAGNOSIS.

While watching the transmission temperature via STAR, wait until the temp reaches just under 45°C/113°F.

The engine must run at idle speed and the transmission oil temperature must not be above the specified transmission oil temperature as too much transmission oil is drained at a higher transmission oil temperature.

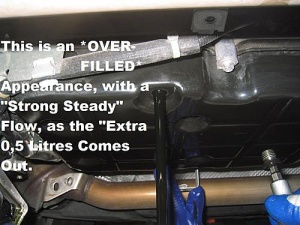

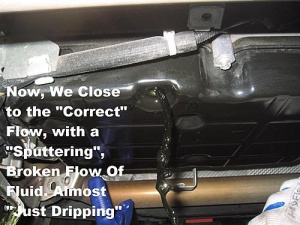

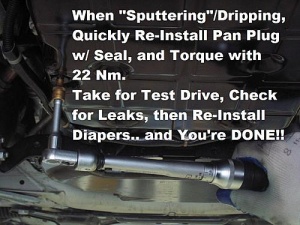

Quickly get under the car and remove the filler adapter and allow the excess fluid to drain out until a small quantity still drains out. Make sure the temp is 45°C/113°F exactly not over or under. Keep checking the temperature and make sure the flow is correct when the temperature is exactly 45°C (exactly and not over or under).

Shut off the engine.

If the fluid flow is not constant after opening the filler adapter, the transmission fluid level has to be corrected and then adjusted again, ie pump in more transmission fluid using the fluid dispenser and the filler adapter. Then retest the level at exactly 45°C as before.

The transmission is now at the correct level.

Final Steps

Clean any excess fluid off of pan and drain plug.

Reinstall the engine covers you removed.