Starter

Starter control, function

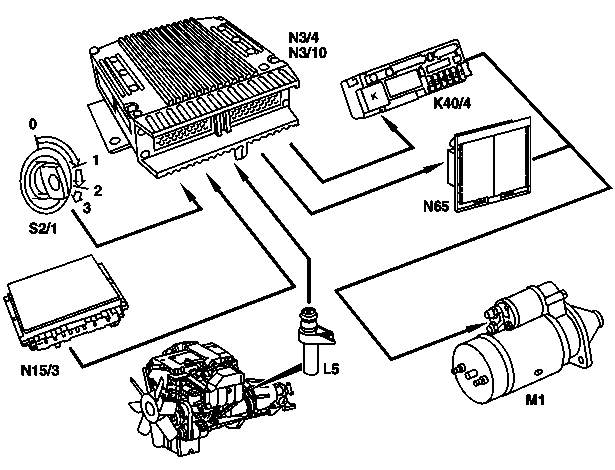

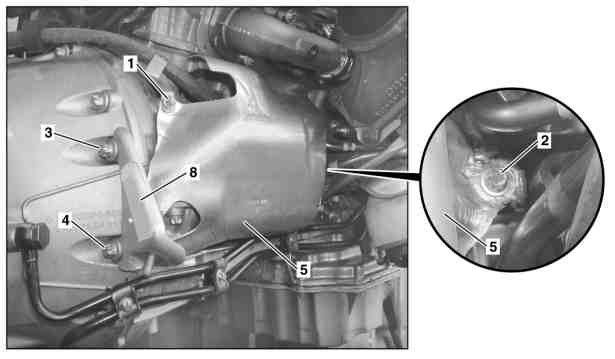

Shown on Engine 111:

|

|

Task

After engine start speed is reached, the circuit (circuit 50) M1 to the solenoid switch of the starter is interrupted.

Design

The solenoid switch of the starter is operated not through the ignition/start switch S2/1, but through the starter relay, by the engine control unit, when in drive position P or N.

The voltage for the starter relay (coil) is supplied through circuit 87. The starter relay is actuated by the engine control unit through GND.

Starter is connected to battery (B+) through front prefuse. According to wiring diagram the wire is unfused.

Function

When the ignition/start switch is operated in the start position, the engine control unit activates an automatic start control. Once the engine start speed of 400 to 700 rpm is reached, the engine control unit interrupts the ground actuation to the starter relay and thus the engine start operation.

Once the engine start operation is initiated, shutting off circuit 50 at the ignition/start switch has no effect. The starter rotates until the specified start speed is reached, or for about 5 seconds at an engine temperature of +80 °C, for a maximum of 10 seconds if the engine is cold.

Start recognition function

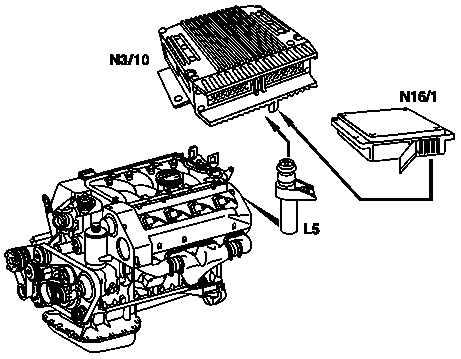

Shown on engine 119:

|

|

Task

Informing the engine control module that the start operation has commenced, in order, for example, to activate start quantity control, start control and post-start enrichment, or to influence the ignition system.

Design/function

The engine control module detects engine start from the first speed signals supplied by the crankshaft position sensor.

Starter relay

When key is turned to start the engine the ignition switch module sends a CAN message to the engine management controller (N3/10) to start the engine; N3/10 then energizes the starter relay that switches power to the motor starter solenoid.

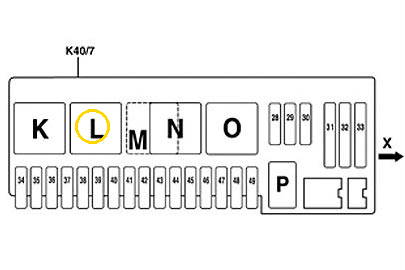

Starter relay (K40/7kL) is located in engine compartment, right rear, inside right front fuse and relay module.

Simple relay test: locate the starter relay and touch it while someone turns the key to see if you can feel it energizing (clicking).

Relay bypass test: remove the relay and connect the relay sockets #30 and #87 with a wire, and turn the key on: this should engage the starter motor. Make sure to remove the jumper wire after the engine has started, otherwise it may damage the starter motor).

Remove starter, install

The complexity of starter removal depends on model (see below for more details):

- In case of 4Matic complete exhaust system has to be removed.

- In case of S400 CDI/S600/S65L AMG right catalytic converter has to be removed.

- In case of S600/S600 PULLMAN front right exhaust system has to be removed.

- In case of S280/S320/S320 CDI/S350/S430/S500 starter can be removed without major problems.

S280/S320/S350/S430/S500/S500 PULLMAN

Valid for:

- ENGINE 112.922 in MODEL 220.063 (S280)

- ENGINE 112.944 in MODEL 220.065/165 (S320, except S320 CDI)

- ENGINE 113.941 in MODEL 220.070/170 (S430, except S430 4Matic)

- ENGINE 113.960 in MODEL 220.075/175/875 (S500/S500 PULLMAN, except S500 4Matic)

- ENGINE 112.972 in MODEL 220.067/167 (S350, except S350 4Matic)

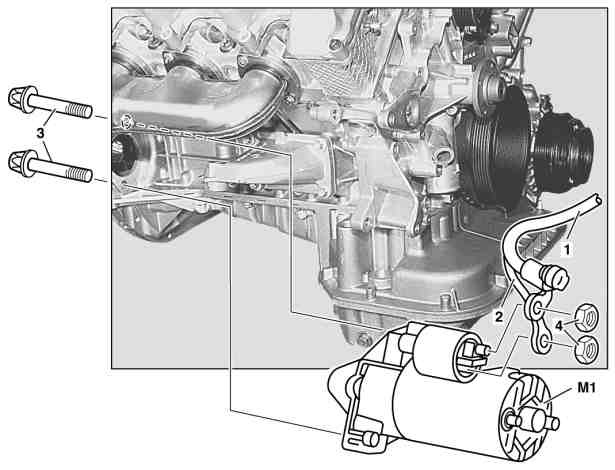

|

|

- Turn key in electronic ignition lock EIS into position "0". Key cannot be withdrawn.

- Dismount ground line to the battery.

- Detach lower engine compartment paneling.

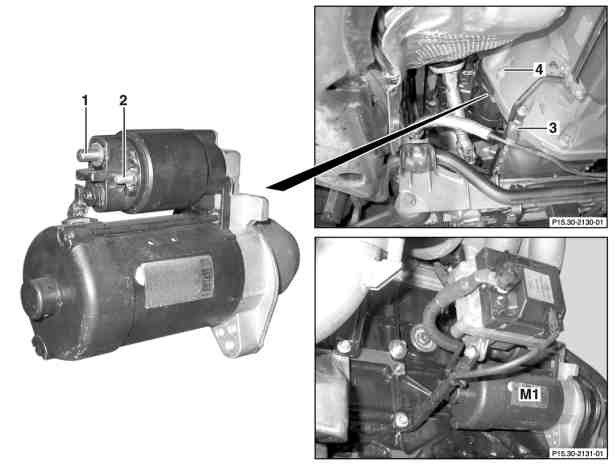

- Unscrew bolts (3)

- Unscrew nuts (4) and remove electrical lines (1, 2).

- Take starter (M1) down and out

- When replacing the starter check ring gear on the drive plate for wear and damage. Rotate engine at the crankshaft in direction of rotation.

- Install in the reverse order

- Render electrical system operational

- Read diagnostic trouble code memory and erase

Torque specification:

- Nut of connection of circuit 30 - Nm 14.

- Nut of connection circuit 50 - Nm 6.

- Bolt of starter to crankcase - Nm 42.

Removal/installation on S350

Starter is attached to transmission and crankcase with two E14 torx bolts. Starter can be removed from underneath the vehicle - only plastic shields have to be removed. Since there is not much space the process is not very convenient but is possible.

|

|

|

|

|

|

|

|

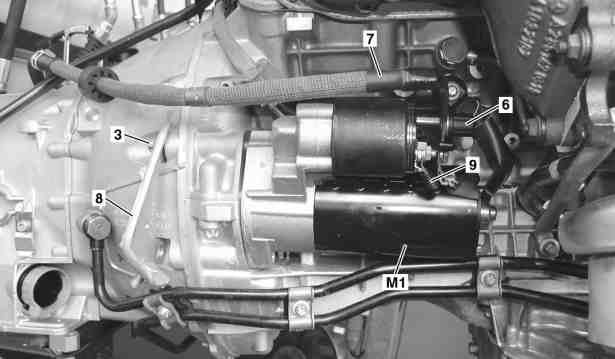

S600/S65 AMG

Valid for:

|

|

|

|

Removing:

- Detach ground line from battery

- Remove right catalytic converter

- Remove bolts (1, 2)

- Loosen bolt (3)

- Remove bolt (4) and remove heat shield (5)

- Detach protection against accidental contact (6) and detach electrical line circuit 30 (7).

- Detach electrical line circuit 50 (9)

- Remove bolt (3) and remove catalytic converter (8)

- Remove starter (M1) from below

- When replacing the starter (M1) check ring gear on drive plate for wear and damage. Rotate engine at crankshaft in direction of rotation.

Install:

- Position starter (M1) at crankcase

- Loosely position bolt (3) with catalytic converter bracket (8)

- Connect electrical line circuit 50 (9)

- Connect electrical line circuit 30 (7) and attach protection against accidental contact (6)

- Loosely position bolts (1,2) on the heat shield (5). Pay attention to cable clamp at bolt (1).

- Loosely position bolt (4). Pay attention to heat shield (5).

- Tighten bolts (3, 4)

- Tighten bolts (1, 2) for heat shield (5)

- Install right three way catalytic converter.

- Connect ground cable to battery

- Carry out function check

- Perform basic programming

- Read out fault memory and erase. When the work is complete stored faults must be worked on in the diagnostic trouble code memories and erased. Connect STAR DIAGNOSIS and read out fault memory.

Torque specifications:

- Nut, connection for circuit 30: 14 Nm

- Nut, connection for circuit 50: 6 Nm

- Bolt connecting starter to crankcase: 42 Nm

- Bolt, heat shield to crankcase: 8 Nm

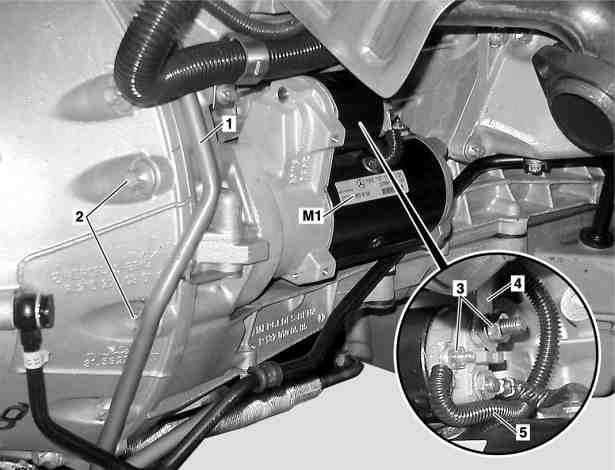

S600/S600 PULLMAN

Valid for:

- ENGINE 137.970 in MODEL 220.178/878 (S600/S600 PULLMAN)

|

|

- Dismount ground line to the battery

- Detach lower engine compartment paneling

- Remove front right exhaust system

- Unscrew bolts of Active Body Control hydraulic line (1)

- Unscrew bolts (2) of starter

- Unscrew nuts (3) and remove electrical lines (4, 5)

- Take starter (M1) down and out

- When replacing the starter (M1) check ring gear on drive plate for wear and damage. Rotate engine at crankshaft in direction of rotation.

- Install in the reverse order

- Perform function check

- Render electrical system operational. Perform basic programming.

- Read out fault memory and erase. When the work is complete stored faults must be worked on in the diagnostic trouble code memories and erased. Connect STAR DIAGNOSIS and read out fault memory.

Torqure specifications:

- Nut, connection for circuit 30: 14 Nm

- Nut, connection for circuit 50: 6 Nm

- Bolt of starter to crankcase: 42 Nm

(S350/S430/S500)

This video shows how to remove the Starter from a W220:

4Matic (S350/S430/S500)

Valid for:

- ENGINE 112 in MODEL 220.087/187 (S350 4Matic)

- ENGINE 113 in MODEL 220.083/183 (S430 4Matic), 220.084/184 (S500 4Matic)

|

|

|

|

|

|

- Disconnect ground line from battery

- Detach lower engine compartment paneling

- Remove complete exhaust system

- Detach heat shield to steering gear

- Dismount exhaust shielding plate (1) for propeller shaft front axle gear

- Detach mounting clamp (2) of electrical line circuit 50 (5) at choke housing

- Detach cap (4) from electrical line circuit 50 (5)

- Unscrew nut of electrical line circuit 50 (5) at starter (M1)

- Unscrew nut of electrical line circuit 30 (3) at starter (M1)

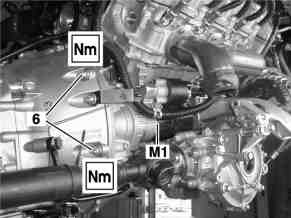

- Remove bolts (6)

- Remove starter (M1) from the rear via the rack-and-pinion steering

- Check ring gear on drive plate for wear and damage. Only when replacing starter. Rotate engine at crankshaft in the direction of rotation of engine.

- Install in the reverse order

- Carry out function check

- Perform basic programming

- Read out fault memory and erase. When the work is complete stored faults must be worked on in the diagnostic trouble code memories and erased. Connect STAR DIAGNOSIS and read out fault memory.

Torqure specifications:

- Nut, connection for circuit 30: 14 Nm

- Nut, connection for circuit 50: 6 Nm

- Bolt connecting starter to crankcase: 42 Nm

S320 CDI (1999-2002)

Valid for:

- ENGINE 613.960 in MODEL 220.026 (S320 CDI)

|

|

- Disconnect ground line from battery

- Remove center and rear bottom sections of soundproofing

- Remove protective cap and detach electrical lines (1,2).

- Remove bolt (3)

- Remove starter (M1) from below

- When replacing the starter (M1) check ring gear on drive plate for wear and damage. Rotate engine at crankshaft in direction of rotation.

- Install in the reverse order

- Carry out function check

- Render electrical system operational. Perform basic programming.

- Read out fault memory and erase. When the work is complete stored faults must be worked on in the diagnostic trouble code memories and erased. Connect STAR DIAGNOSIS and read out fault memory.

Torqure specifications:

- Bolt connecting starter to crankcase: 42 Nm

- Nut, connection for circuit 30: 14 Nm

- Nut, connection for circuit 50: 6 Nm

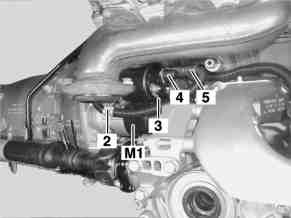

S320 CDI (2003-2006)

Valid for:

- ENGINE 648 in MODEL 220 (S320 CDI 2003-2006)

|

|

- Remove bottom section of soundproofing

- Disconnect circuit 30 (1)

- Disconnect circuit 50 (2)

- Detach bracket (3)

- Remove bottom bolt (4). Insert a long extension at rear engine mount via transmission to loosen upper bolt.

- Take starter (M1) down and out

- Install in the reverse order

- Read out fault memory. Connect STAR DIAGNOSIS and read out fault memory.

- Perform basic programming

Torqure specifications:

- Bolt connecting starter to crankcase: 42 Nm

- Nut, connection for circuit 30: 14 Nm

- Nut, connection for circuit 50: 6 Nm

S400 CDI

Valid for:

- ENGINE 628.960 in MODEL 220.028 (S400 CDI)

|

|

|

|

- Disconnect ground cable from battery

- Remove bottom sections of soundproofing

- Lower front axle carrier

- Remove fan shroud

- Remove right catalytic converter

- Remove bottom right charge air pipe (1). Do not detach bottom charge air pipe (1) from charge air hose. Place released bottom charge air pipe (1) only to the side. Installation: Attach bottom charge air pipe (1) with new sealing ring to the turbocharger.

- Remove protective cap and dismount electrical line circuit 50 (2) and electrical line circuit 30 (3) at starter (M1)

- Unscrew bolts (4) of starter (M1)

- Take starter (M1) down and out

- When replacing the starter check ring gear on the drive plate for wear and damage. Rotate engine at torque converter in direction of rotation of engine.

- Install in reverse order

- Perform function check

- Make electrical system ready for operation. Perform basic programming.

- Read out fault memory. Connect STAR DIAGNOSIS and read out fault memory.

Torqure specifications:

- Nut, connection for circuit 30: 14 Nm

- Nut, connection for circuit 50: 6 Nm

- Bolt connecting starter to crankcase: 42 Nm

Parts

| Part No. | Notes |

|---|---|

| A0061510501 | For S350. From Date: 30/10/2003. Voltage: 12V, Kilowatt: 1.4kW, Rotation: CW, Teeth: 10T. Borg & Beck part number: BST2087. Bosch part numbers: 0986021280, 0001108404, 0001108403. |

| A0051516501 | For S350. To Date: 30/10/2003. Voltage: 12V, Kilowatt: 1.4kW, Rotation: CW, Teeth: 10T. Bosch part numbers: 0986019507, 0986019500, 0001108197. |

| A0061510601 | For S430/S500. From Date: 30/10/2003. Voltage: 12V, Kilowatt: 1.7kW, Rotation: CW, Teeth: 10T. Bosch part numbers: 0986021290, 0001108213. |

| A1121510001 | For S430/S500. To Date: 30/10/2003. Voltage: 12V, Kilowatt: 1.7kW, Rotation: CW, Teeth: 10T. Bosch part numbers: 0001115005, 0001115004, 0001108213, BX1789, 0986017890. |

| N910105010044 | Bolt M10X90. Starter to crankcase and transmission. |