Alternator: Difference between revisions

No edit summary |

(Replacing alternator / Replacing alternator voltage regulator) |

||

| Line 61: | Line 61: | ||

'''Note:''' This method is not suitable for testing the voltage of [[battery]], since several consumers activated will cause a non-objective measurement. [[Battery]] voltage must be measured without active consumers (i.e. with minimal load) and only across the [[battery]] terminals. | '''Note:''' This method is not suitable for testing the voltage of [[battery]], since several consumers activated will cause a non-objective measurement. [[Battery]] voltage must be measured without active consumers (i.e. with minimal load) and only across the [[battery]] terminals. | ||

==Replacing | ==Replacing alternator== | ||

# Disconnect negative battery cable. This is important to make sure that when disconnecting alternator battery wire (B+) it does not get shorted to chassis. | |||

# Remove [[serpentine belt]]. | |||

# Remove oil dipstick to not accidentally breake it off (important on S500). | |||

# Removing alternator bolts. The bolts are Torx 16, but 11mm socket will work fine too. | |||

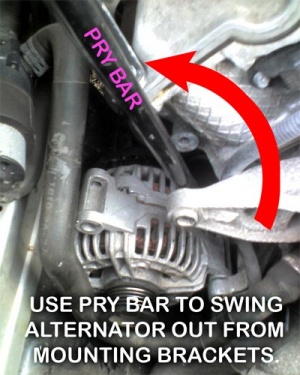

# Tilt alternator out of bracket. Use pry bar if needed (see below). | |||

# Rotate alternator pulley down (see photo below) and remove wires. Battery wire needs 13mm socket. The other wire pulls of easily. | |||

# Remove alternator from the car. S350 has a lot of space to do that. S500 has less space therefore removal will involve some difficulties. Removal of auxillary fan motor will help to get more space (it is only 3 10mm bolts). | |||

# Reinstall in opposite order. It will be easier to push alternator in lower bracket first. To ease installation metal washers can be pushed out of bolt holes. | |||

http://www.benzworld.org/forums/w220-s-class/1688209-alternator-voltage-regulator-replace-diy.html | {| | ||

|[[File:W220_alternator_pry_bar_usage.jpg|thumb|none|Using pry bar to release the alternator from mounting brackets.]] | |||

|[[File:W220_alternator_rotated.jpg|300px]] | |||

|[[File:W220_alternator_removed.jpg|300px]] | |||

|} | |||

<!-- http://www.benzworld.org/forums/w220-s-class/1688209-alternator-voltage-regulator-replace-diy.html --> | |||

==Replacing alternator voltage regulator== | |||

Most of the time failed alternator can be fixed by replacing cheap voltage regulator (i.e., in case brushes are worn). | |||

See video below for voltage regulator replacement. | |||

{| | |||

|{{#ev:youtube|https://www.youtube.com/watch?v=lqDgdtHZUzU|320|center|Alternator voltage regulator replacement.|frame}} | |||

|} | |||

Revision as of 18:29, 23 July 2019

Back to Index

Specification

W220 are equipped with two types of alternators. With and without coolant cooling.

- S350, S430, S500: 14V/150A (part no 0986047550)

- S55: 14V/180A

- S600: 14V/220A

There are several part numbers compatible to each other.

Faulty Alternator

Symptoms

A faulty alternator will fail to charge battery and in a very extreme cases will cause a warning message "BATTERY CHARGE VISIT WORKSHOP!" to be displayed in dashboard.

|

Typical symptoms are:

- Charging voltage across battery terminal with engine running below about 13.8V.

- Alternator output voltage greater than about 15V. A good fully charged battery should be about 14.2V across the battery terminals.

- Illumination change in instrument cluster is usually an early indicator of pending alternator failure.

- A sudden sound of the alternator (high frequency whine) disappearance.

- Clicking sounds from the doors caused by car unlocking itself for safety purposes.

Causes

An alternator can fail or perform poorly due to:

- Bearings worn or noisy

- Voltage regulator electronic component failure

- Brushes worn

- Cable fracture

- Full wave bridge diode open or short circuit

- Stator winding open or short circuit

- Rotor winding open or short circuit

- Serpentine belt issues

The W220 has very good in-built electronic checking systems and so you should be alerted to the usual failure mechanisms by the car itself. With some electronic capability and the right tools it is easy to diagnose most alternator electrical issues. Mechanical problems are usually diagnosed by hearing unusual sounds from the alternator.

Checking Alternator Voltage

Follow the steps below to obtain the alternator voltage readings via the instrument cluster hidden menu.

Start the vehicle. After few seconds the voltage display will disappear. However, you can locate it again using steering wheel buttons. The voltage reading with the vehicle running should be displayed.

Correct voltage measurement on alternator should be around 14V (the voltage value must not fluctuate - see video of faulty alternator below).

Sometimes the problem can be in the circuit to the battery. To test whether the battery actually receives the voltage generated by alternator, use an accurate Digital Volt Meter (DVM) and monitor the alternator output across the battery terminals. It should match voltage displayed on the instrument cluster.

Note: This method is not suitable for testing the voltage of battery, since several consumers activated will cause a non-objective measurement. Battery voltage must be measured without active consumers (i.e. with minimal load) and only across the battery terminals.

Replacing alternator

- Disconnect negative battery cable. This is important to make sure that when disconnecting alternator battery wire (B+) it does not get shorted to chassis.

- Remove serpentine belt.

- Remove oil dipstick to not accidentally breake it off (important on S500).

- Removing alternator bolts. The bolts are Torx 16, but 11mm socket will work fine too.

- Tilt alternator out of bracket. Use pry bar if needed (see below).

- Rotate alternator pulley down (see photo below) and remove wires. Battery wire needs 13mm socket. The other wire pulls of easily.

- Remove alternator from the car. S350 has a lot of space to do that. S500 has less space therefore removal will involve some difficulties. Removal of auxillary fan motor will help to get more space (it is only 3 10mm bolts).

- Reinstall in opposite order. It will be easier to push alternator in lower bracket first. To ease installation metal washers can be pushed out of bolt holes.

|

|

|

Replacing alternator voltage regulator

Most of the time failed alternator can be fixed by replacing cheap voltage regulator (i.e., in case brushes are worn). See video below for voltage regulator replacement.