Rear axle

Back to: WIS 32.00 General

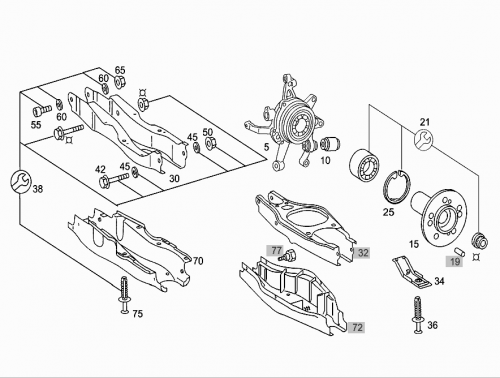

Identification - Rear Drive/Axle Suspension

Components - Rear Drive/Axle Suspension

Lower Bushing - Rear Drive/Axle Suspension

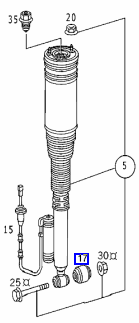

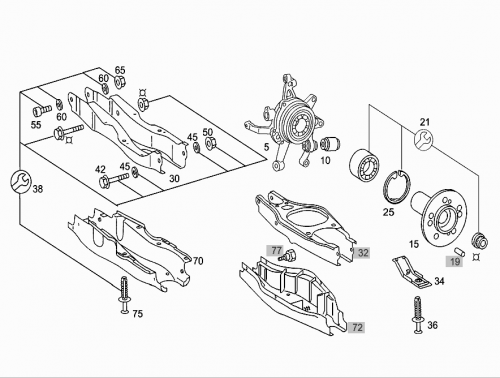

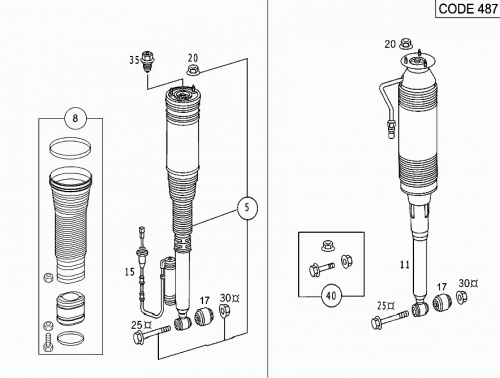

The Lower Rear Axle Suspension Bushing, item (17) and item (10) below, is located at the strut supporting joint in the wheel carrier.

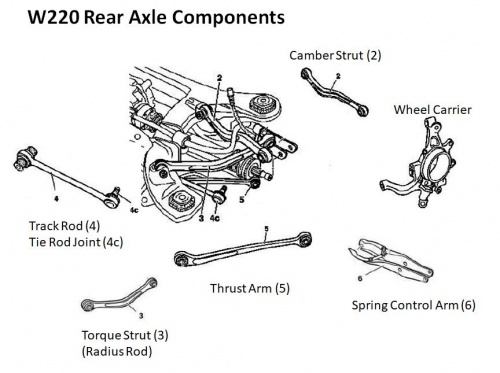

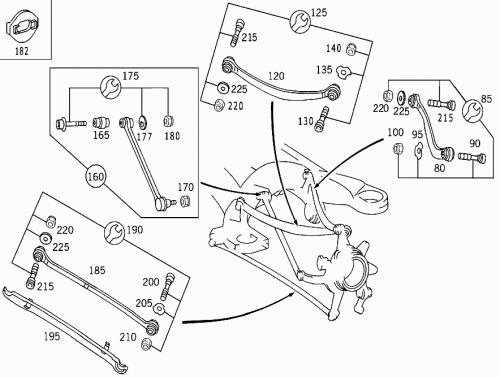

Designations - Rear Axle Suspension

Identifying the components in this diagram with same nomenclature as above.

- Item 95 Camber Srut (2)

- Item 120 Torque Strut (3) (Radius Rod)

- Item 160 Track Rod (4), Tie Rod Joint (4c)

- Item 185 Thrust Arm (5)

Issues - Rear Drive/Axle Suspension

- Squeaking, creaking noises from the rear axle suspension is a common problem.

- The axlel ball joints that look like bushings lose their internal lubrication.

There is a ball joint at the bottom of each suspension AIRmatic strut and another one at the back of the wheel spider. Four ball joints in total. There is no part number for the bottom strut ball joints but they are the same as the outer ones.

It is recommend to replace both the strut ball joints and the outer ball joints when during replacement.

Parts - Rear Suspension

- M-B: A2203520027.

- TRW: JBU167.

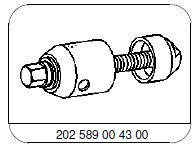

Tools - Rear Suspension

- To remove and replace the bushing a special tool is needed.

- Removal and Installation Tool W202589004300 (see Special Tools page).

DIY Tasks - Rear Suspension

Assessing Wear - Rear Suspension

Use a large shifting spanner (handle 300mm long) to tightly grip each Rear Axle Component in turn. Measure the movement at the end of the spanner handle as force is applied. The results will give an indication of the amount of wear occurring in each axle component.

Typical results for a W220 with 240,000Km;

| Rear Axle Component | Rear Left (RL) Measurements [mm] | Rear Right (RR) Measurements [mm] |

|---|---|---|

| Camber Strut (2) | 15 | 10 -15 |

| Torque Strut (3) | 20 | 30 |

| Track Rod (4) | 15 - 20 | 10 |

| Thrust Arm (5) | 1 -2 | 1 -2 |

| Tie Rod (25) | 0 | 0 |

The conclusion with these results was that the Torque Struts need replacing. Consequently it was decided to replace all possible wear components while the rear end was dismantled. See below for DIY.

Rear Shock Absorber - Rubber Lower Bushes

Temporary Fix - Rubber Lower Bushes

A quick temporary fix is to make a slit in the rubber seal and inject some oil.

Full Replacement - Rubber Lower Bushes

Reference: WIS AR32.25-P-1871M Replace rubber mounts of rear shock absorbers

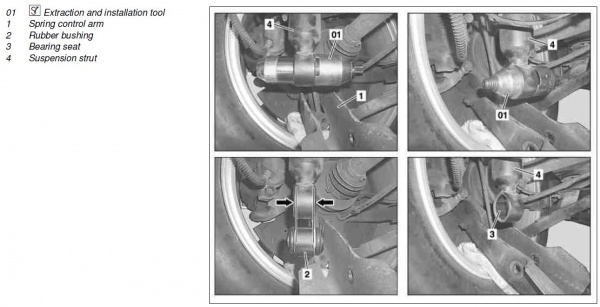

Designations - Rubber Lower Bushes

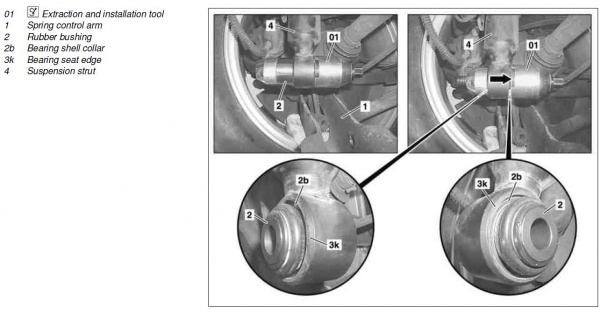

Removal - Rubber Lower Bushes

- Empty suspension strut (4) of rear axle using STAR DIAGNOSIS.

- Partially remove spring control arm (1). TIP: Unhook exhaust system on both rear exhaust-rubber mounts. TIP: Detach spring control arm from rear axle carrier and swing downwards.

- Remove rubber mounts (2) using extraction and insertion tool (01). AIRmatic Lower Rubber Bushes - Rear Suspension

- Clean and check bearing seat (3).

Installation - Rubber Lower Bushes

- Install rubber mounts (2) using extraction and insertion tool (01). TIP: Do not squeeze plastic parts (large arrow) of the rubber mount (2). Cracked plastic parts result in corrosion and thus to damage to the rubber mount(2).

- Check installation position of the rubber mount (2). TIP: Carry out visual inspection of distances (small arrows) from outer bearing shell collar (2b) to the bearing seat edge (3k). In the event of unequal distances (small arrows) correct the installation position using the extraction and insertion tool (01).

- Install spring control arm (1). TIP:Unhook exhaust system on both rear exhaust-rubber mounts.

- Fill the suspension strut (4) using STAR DIAGNOSIS. TIP: The wheels must not touch the ground while pressurizing because the air spring bellows in the suspension strut (4) will be destroyed if pressurized with the suspension compressed.

- Check AIRmatic for leaks.

Resources - Rear Suspension

http://www.benzworld.org/forums/w210-e-class/1602887-diy-r-r-outer-bushing-rear.html

http://www.benzworld.org/forums/w201-190-class/1673624-worn-out-hub-carrier-bushing-3.html

http://www.benzworld.org/forums/w220-s-class/1623753-loud-creaking-rear-03-w220-4matic.html

http://www.benzworld.org/forums/w220-s-class/1695182-w220-04-s600-abc-issue-squeaking.html

How to change subframe bushes: http://forums.mercedesclub.org.uk/showthread.php?t=90826 and http://forums.mercedesclub.org.uk/showthread.php?t=90827 .