Fuel pump filter

Fuel pump and filter is mounted on the left frame floor in front of the rear axle.

|

|

Fuel Pump

|

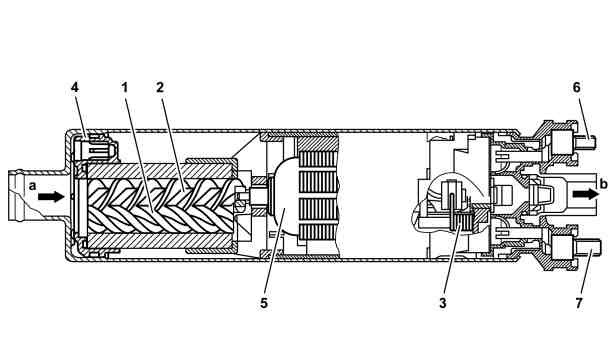

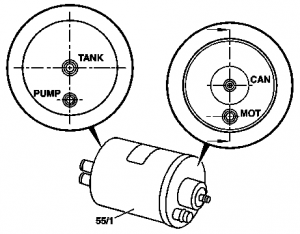

Illustration shows screw spindle pump

|

The task of the pump is to supply an adequate quantity of fuel to the

fuel system at the required pressure in all driving states.

On model W220 helical spindle pump is mounted at frame floor.

The fuel pump (M3) pumps more fuel than the engine requires in total in order to maintain the pressure in the fuel system in all operating states. As a result of this circulation, relatively cool fuel is available at all times for injection (avoids the formation of vapor bubbles). A pressure relief valve (4) is integrated in the fuel pump in order to limit the pressure.

The check valve (3) in the fuel pump decouples the fuel system from the fuel tank by preventing fuel from flowing back through the fuel pump to the fuel tank. The fuel pump is actuated by the engine control unit through the fuel pump relay.

Parts

To date: 30/06/2001 (with screw connections):

- OE - A0004707894 (EUR 370)

From date: 30/06/2001 (with pluggable connections):

- OE - A0014701294 (EUR 370)

- OEM - PIEBURG 7.28126.51.0 (EUR 155)

- BOSCH 0986580354 (EUR 173)

- TOPRAN 401632 (EUR 95)

- STARKE 162-029 (EUR 30)

The manufacturer of the original fuel pump is PIEBURG. Special workshops are able to open them and replace any faulty parts. The inner design of cheaper pumps is different, which leads to lower quality and noisy operation, therefore, in case of fuel pump failure, if possible, the original PIEBURG pump should be repaired.

The part number for pluggable electrical connector on the vehicle side - A1685452728. The male part of the pluggable electrical connector on the pump side is TRUCKTEC/29.3086. The male connector can be used to convert pre-facelift fuel pump with screw connections to a pluggable connection (see the pictures below).

|

|

|

|

|

Filter

The task of the fuel filter is to filter impurities out of the fuel, maintaining constant fuel pressure in wide limits irrespective of the fuel pump delivery.

|

|

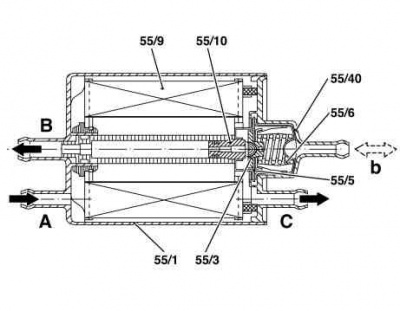

The fuel filter consists of a sheet metal casing with an integrated filter element (55/9). The fuel flows through this from the outside to the inside. As a result any impurities are trapped.

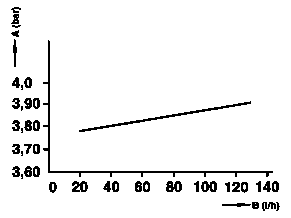

The diaphragm pressure regulator (55/40) controls the fuel pressure of approx. 3.8 bar (operating pessure) via the fuel return flow quantity to the fuel tank.

If the set fuel pressure is exceeded, the diaphragm (55/5) is pushed against the push spring (55/6) and the valve (55/3) attached to the diaphragm opens the passage for the fuel return to the fuel tank (B). If the set pressure is below the limit, the valve is closed again by means of the push spring.

|

|

A greatly varying fuel pump delivery (e.g. 20 or 140 l/h) does not have any great effect on the fuel pressure.

Parts

- A0024773001 OE (EUR 85)

- MANN-FILTER WK 720 (EUR 60)

- Blue Print ADA102301 (EUR 15)

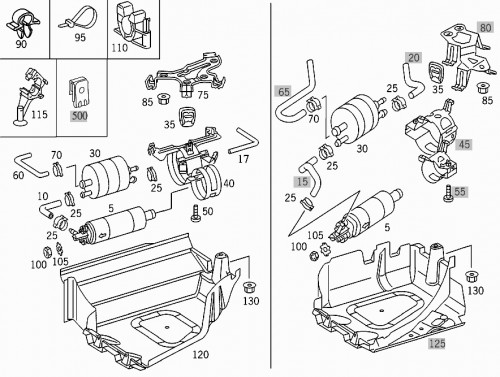

Fuel pump package

Identifying the components in this diagram with same nomenclature as above:

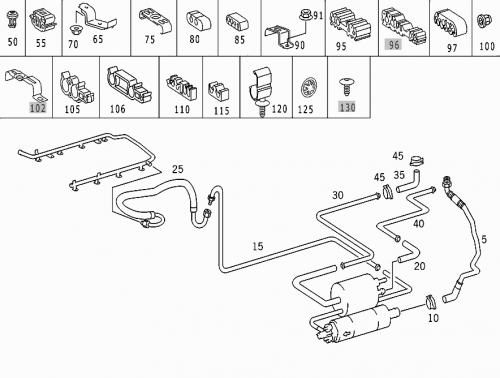

Fuel lines (gasoline vehicles)

Identifying the components in this diagram with same nomenclature as above:

| Part | Part no. | Image | Description |

|---|---|---|---|

| 10 | A0069971990 |

|

Clamp. Fuel hose to fuel pump 21.5-22.5 MM |

| 20 | A2104765527 | Hose. Breather line to fuel filter |

Testing fuel pressure

Remove Schrader valve cap from the fuel rail fuel pressure port and connect your fuel pressure tester. Be extremely careful during this test procedure as if fuel falls on hot engine parts it may cause a fire. Never carry this test if the engine is hot.

The fuel pressure should build up as soon as you turn on the ignition before you even try to crank the engine and the pressure should not drop after turning on the ignition. The pressure reading should be around 3.8 bars. If the pressure is not maintained then the cause can be either a faulty fuel filter or a faulty fuel pump.

Fuel pump and filter replacement